Construction method of directional hole in upward penetration layer on top plate for gas drainage in underground coal mine

A gas drainage and construction method technology, which is applied in the direction of gas discharge, directional drilling, mining equipment, etc., can solve the problems of short extension distance of fracture zone, long construction period, low drilling efficiency, etc. The effect of large hole coverage area and high drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The implementation of the present invention will be described in detail below through examples and in conjunction with the accompanying drawings. in,

[0034] Example:

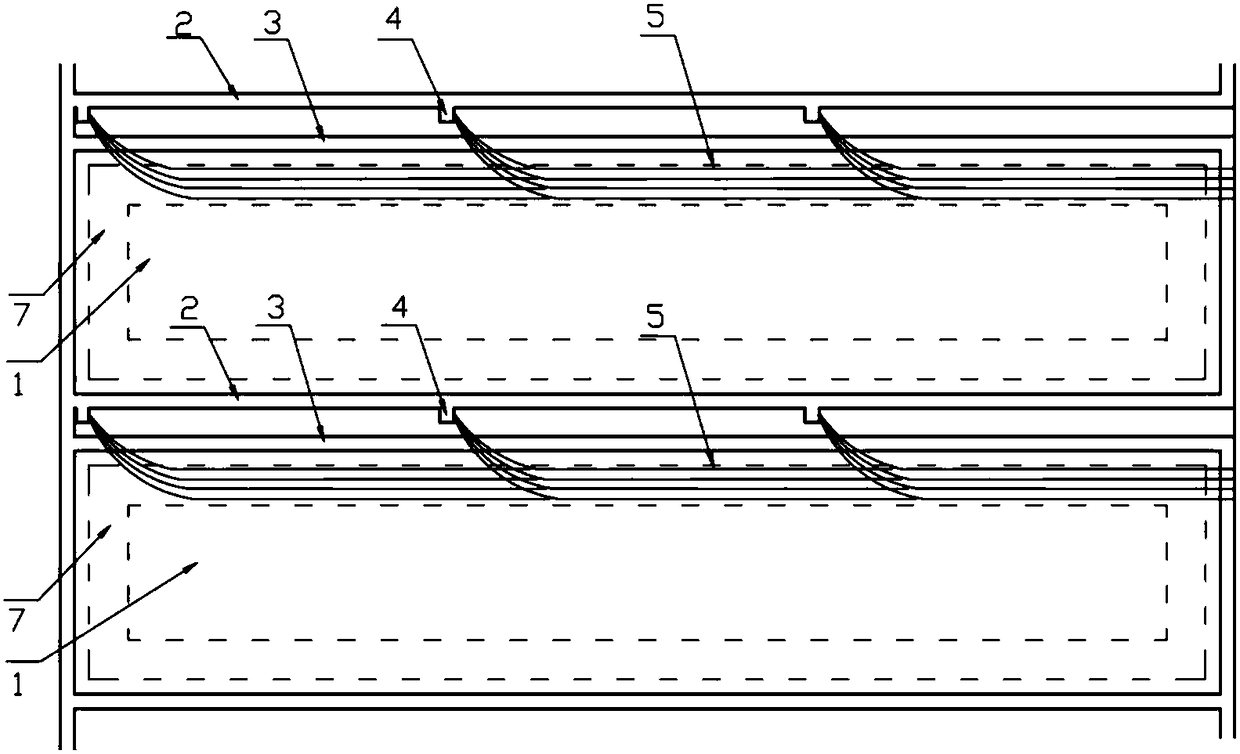

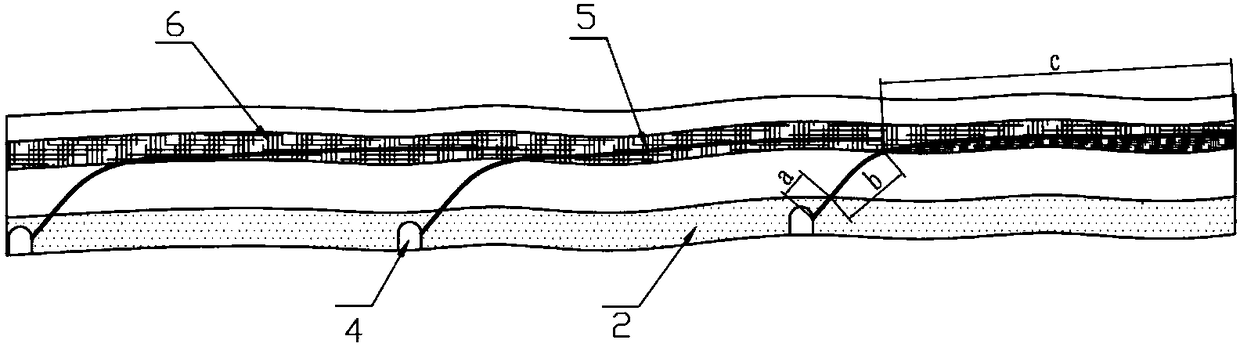

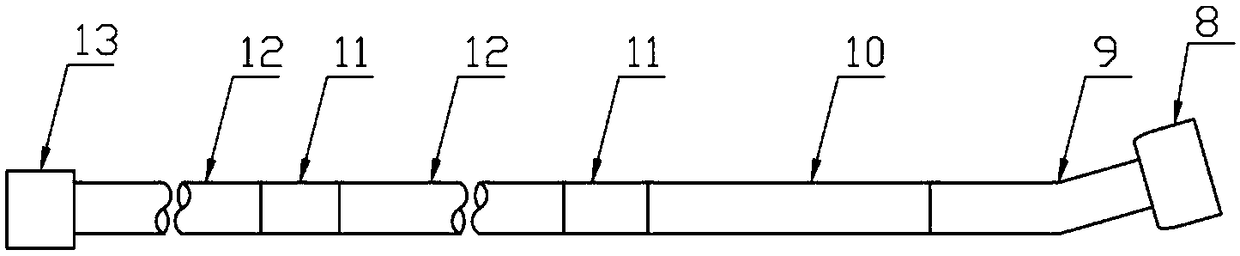

[0035] see figure 1 , figure 2 , a method for constructing directional holes in the upward penetration layer on the roof of coal mine underground mining gas drainage, characterized in that it includes the following steps:

[0036] Step 1: Drill site 4 preparation. A plurality of drilling sites 4 have been developed in the wind tunnel 2 of the adjacent working face of the working face 1 to be mined in the underground, and the distance between the adjacent drilling sites 4 is equal to the horizontal projection length of the directional hole 5 of the directional stabilizing hole section c of the upward penetration layer on the top plate .

[0037] Step 2: Drill hole design. According to the mine coal seam roof occurrence and mining plan, the existing model simulation analysis and theoretical formula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com