Developable curved surface tubular structure

A technology of tubular structure and curved surface, which is applied in the direction of building components, building structures, buildings, etc., can solve problems such as difficult to control deformation, and achieve the effects of low production cost, convenient processing, and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: An embodiment of a rectangular tubular structure with equal cross-section and curved surface.

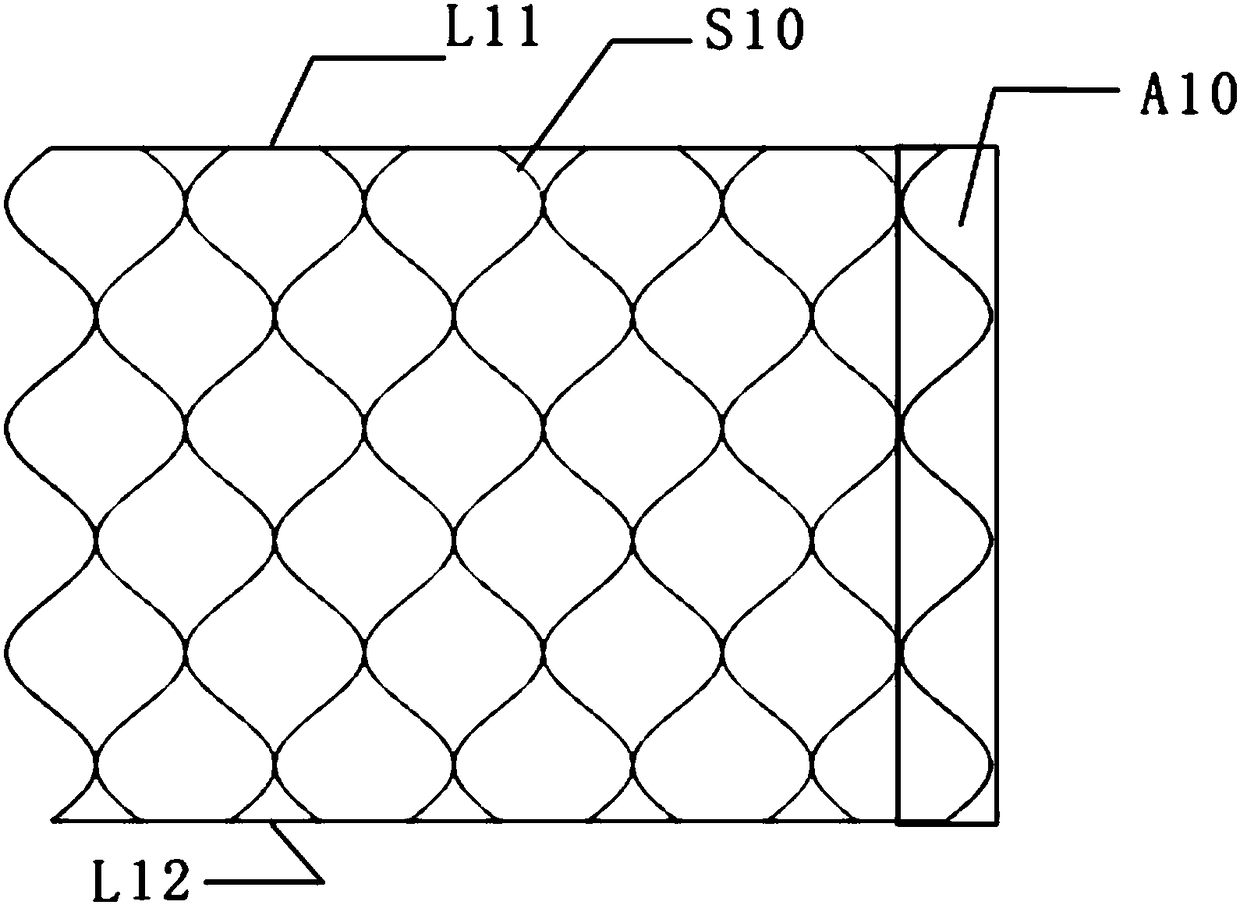

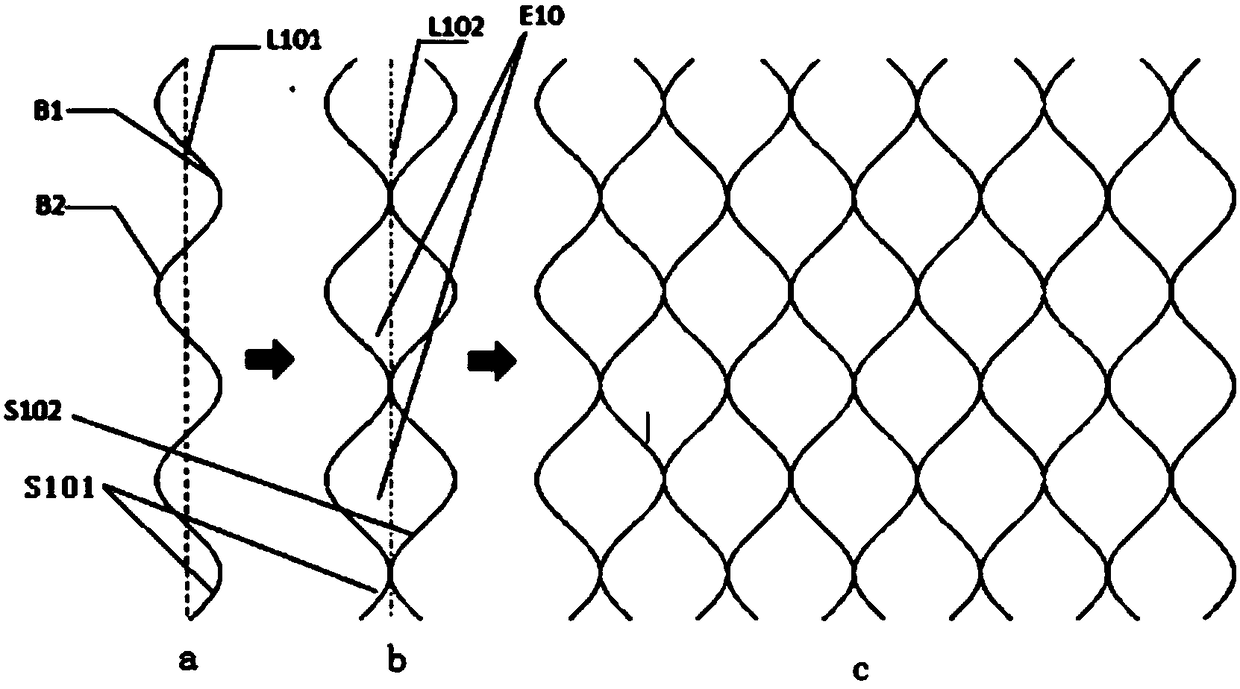

[0032] Such as figure 1 As shown, it represents a curved tubular structure, including a number of "S"-shaped curved indentations S10 uniformly arranged on the sheet material, and the curved creases are surrounded by four indentations parallel to the circumferential direction and uniform in two directions. The edge is diamond-shaped, and one end of the thin plate is provided with a glue point A10, which is used for glue after curling. The thin plate material can be cardboard, PP board and other materials, and the size of the thin plate is about A4 (293mm*210mm). The indentation is processed by a laser engraving machine. In this embodiment, there are 11 curved marks S10 in total, which are evenly distributed along the horizontal direction, and the cross-section will form a regular pentagon after curling. The viscose used in the pasting area A10 in this embodime...

Embodiment 2

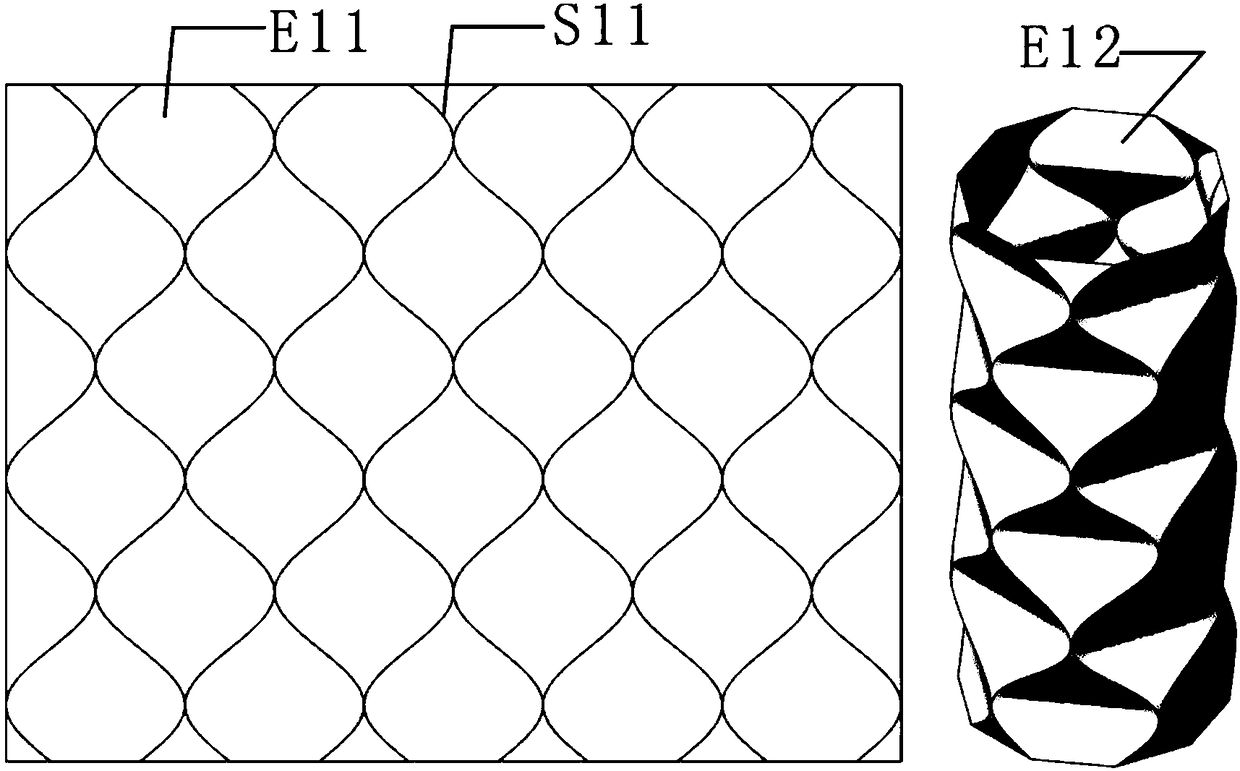

[0038] Such as Figure 4 As shown; the difference between this embodiment and the previous embodiment 1 is that the curvature S21 is different, and will be surrounded by a curved rhombus unit E21. A total of 13 curved marks are evenly distributed, forming a regular hexagonal cross-section after the thin plate is curled. In the vertical direction, there are 2 groups of crests and troughs, forming 2 curved diamond-shaped units E21 in the vertical direction of the thin plate, that is, 2 curved surface units E22 in the axis direction of the curled origami tubular structure. After folding and compressing according to the operation steps in the above examples, evenly distributed small curved surface structures can still be formed on the surface of the cylinder. The curved diamond-shaped unit E22 formed by this kind of curved indentation is relatively tall and thin, and the finished product is as follows Figure 4 As shown on the right, different from Example 1, different structural...

Embodiment 3

[0040] Such as Figure 5 Shown; The difference between this embodiment and the above-mentioned two embodiments is that the shape fluctuation range of its curved creases is relatively large, and the curves S31 are arranged in a staggered manner, and a complete curved rhombus unit is not formed on its limited height, such as As shown in the figure, unit E31 in the figure. After curling, an incomplete curved diamond-shaped unit E32 is formed. After folding and compressing according to the operation steps in the above-mentioned embodiments, a small curved surface structure E32 can also be formed on the surface of the tubular structure, and finally a finished product such as Figure 5 shown on the right.

[0041] To sum up, with the above composition of the present invention, the user can easily and quickly make the expandable tubular structure with regularly distributed concave-convex small curved surfaces through steps such as manual folding, pressing, and pasting. In the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com