Base-containing high-entropy alloy composite and preparation method thereof

A technology of high-entropy alloys and composite materials, applied in the field of high-entropy alloys and their preparation, can solve the problems of inability to improve mechanical strength and plasticity, high brittleness, etc., and achieve excellent comprehensive mechanical properties and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

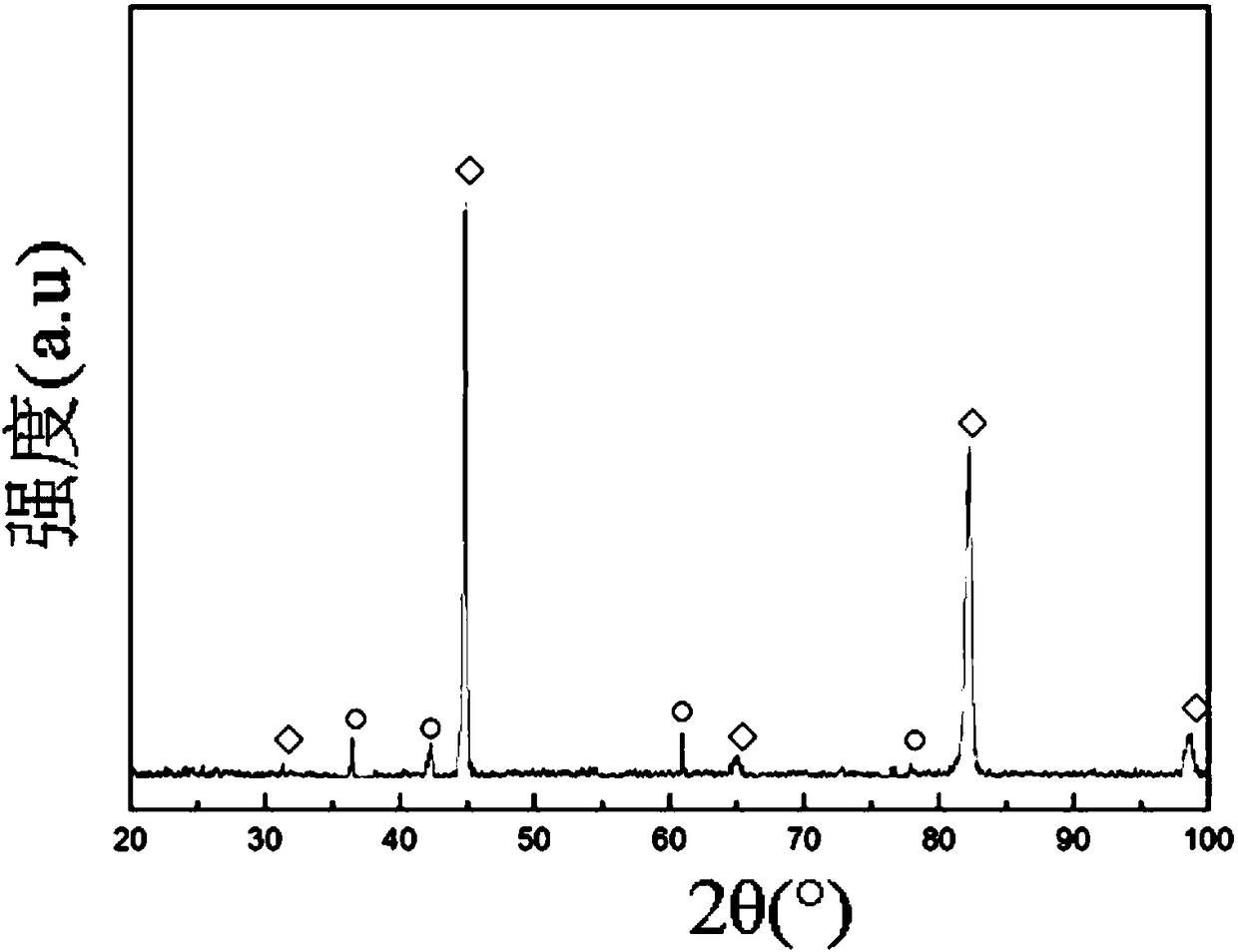

Image

Examples

specific Embodiment approach 1

[0023] Specific Embodiment 1: This embodiment is a base-based high-entropy alloy composite material prepared from 1% to 20% of the reinforcement phase and 80% to 99% of the base-based high-entropy alloy matrix according to the mass percentage; the reinforcement phase TiC, TiB 2 , TiB, B 4 C or Al 2 o 3 ; The base-based high-entropy alloy matrix is composed of 50% to 90% alloy matrix and 10% to 50% alloying elements by mass fraction; the alloy matrix is Fe, Al, Cr, Ni, Co, Cu, One or two elements in Ti, Mn, Mo, Zr, Hf, Nb and Sn; the alloying elements are Fe, Al, Cr, Ni, Co, Cu, Ti, Mn, Mo, Zr , Hf, Nb, and Sn, or two or more elements; when the alloy matrix is composed of two elements, the molar ratio between the two elements is b, and the range of b is 0.5≤b≤ 2. The molar ratio between any two elements of the alloying elements is a, and a satisfies: 0.8≤a≤1.25.

specific Embodiment approach 2

[0024] Specific embodiment two: This embodiment is a method for preparing a base-based high-entropy alloy composite material, which is completed in the following steps:

[0025] 1. Weighing 1% to 20% of the reinforcing phase and 80% to 99% of the base-based high-entropy alloy matrix according to the mass percentage to obtain the base-based high-entropy alloy composite material raw material;

[0026] The reinforcement phase described in step 1 is TiC, TiB 2 , TiB, B 4 C or Al 2 o 3 ;

[0027] The base-based high-entropy alloy matrix described in step 1 is composed of 50% to 90% alloy matrix and 10% to 50% alloying elements by mass fraction; the alloy matrix is Fe, Al, Cr, Ni, Co, One or two elements in Cu, Ti, Mn, Mo, Zr, Hf, Nb and Sn; the alloying elements are Fe, Al, Cr, Ni, Co, Cu, Ti, Mn, Mo , Zr, Hf, Nb and Sn, or two or more of them; when the alloy matrix is composed of two elements, the molar ratio between the two elements is b, and the range of b is 0.5≤ b≤2;...

specific Embodiment approach 3

[0033] Embodiment 3: The difference between this embodiment and Embodiment 2 is that in step 1, 10% of the reinforcement phase and 90% of the base-based high-entropy alloy matrix are weighed by mass percentage to obtain the base-based high-entropy alloy composite material raw material. Other steps are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com