PVC (polyvinyl chloride) composite material for bags and suitcases and preparation process thereof

A composite material and luggage technology, applied in the field of polymer material preparation, can solve the problems of decreased physical and mechanical properties, poor light and thermal stability, poor aging resistance, etc., and achieve long service life, good aging resistance, and strong weather resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

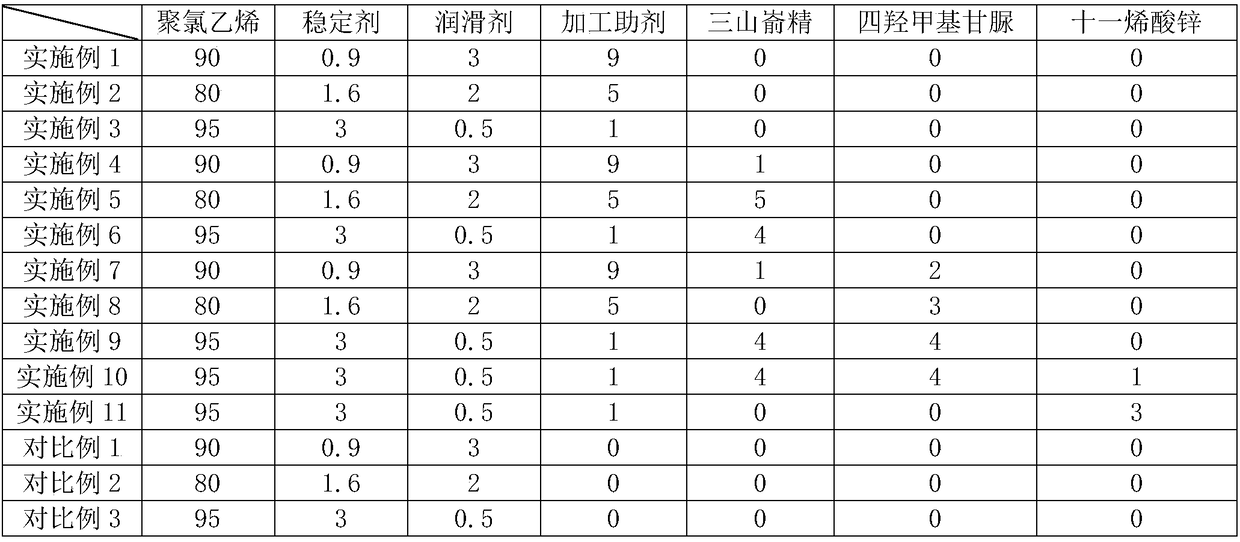

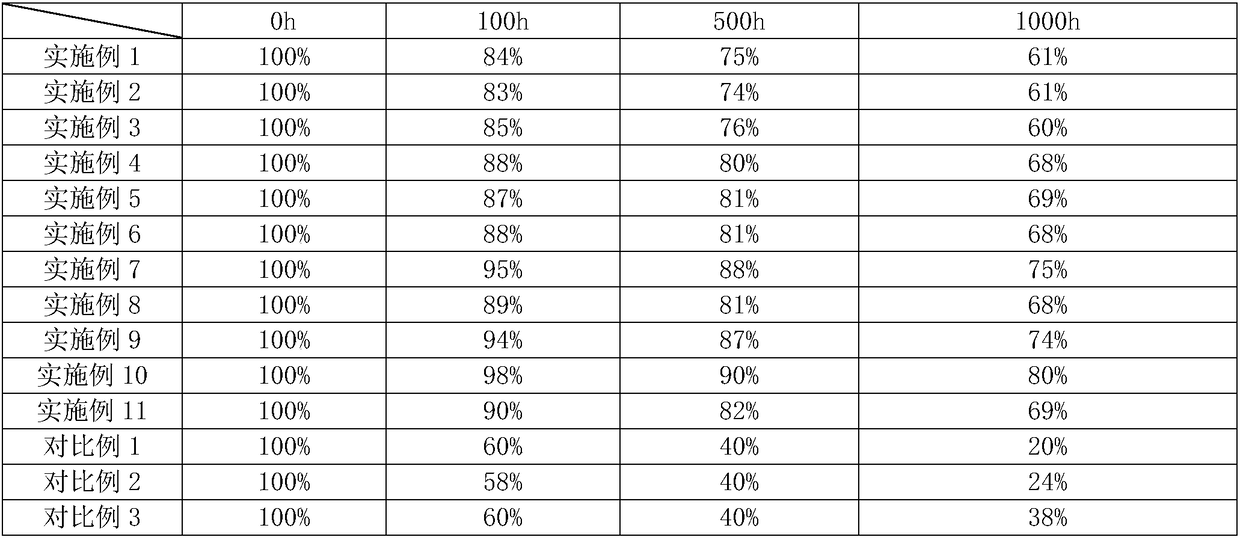

Embodiment 1

[0020] Example 1: A PVC composite material used for bags, the components and contents of the raw materials are shown in Table 1, and the unit of each component in Table 1 is kg. Wherein the stabilizer is dibutyltin dilaurate, the lubricant is butyl stearate, and the processing aid is sucrose tribehenate.

[0021] The preparation process of the PVC composite material used for bags is as follows: the following steps are included, step 1, batching, taking each component in the raw material, heating to 80°C, and stirring evenly; step 2, extruding, cooling the material in step 1 to 30 ℃, sent to the extruder for extrusion, the heating temperature of the extruder is controlled at 140-150 ℃, and the plasticizing temperature of the material is controlled at 150-180 ℃; Step 3, calendering, calendering the material extruded by the extruder, calendering roller The temperature is controlled at 150-180°C; step 4, cooling and winding, after the sheet calendered by the calender is cooled, wi...

Embodiment 2

[0022] Embodiment 2: A kind of PVC composite material that is used for luggage, the difference with embodiment 1 is that each component of raw material and content are as shown in table 1, and wherein, stabilizer is di-n-octyltin dilaurate, lubricant It is glycerol monooleate, and the processing aid is sucrose tribehenate.

Embodiment 3

[0023] Embodiment 3: a kind of PVC composite material that is used for luggage, the difference with embodiment 1 is that each component of raw material and content are as shown in table 1, and wherein, stabilizing agent is dibutyltin maleate, and lubricant is Monoglyceride Stearate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com