A kind of low Curie temperature point PTC organic composite material and preparation method thereof

A technology of composite materials and temperature points, which is applied in the field of constant temperature materials, low Curie temperature PTC organic composite materials and their preparation, can solve the problems of limiting PTC composite materials, difficulty, and lowering the melting point of composite materials, so as to improve the strength of PTC , lower the melting point, and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

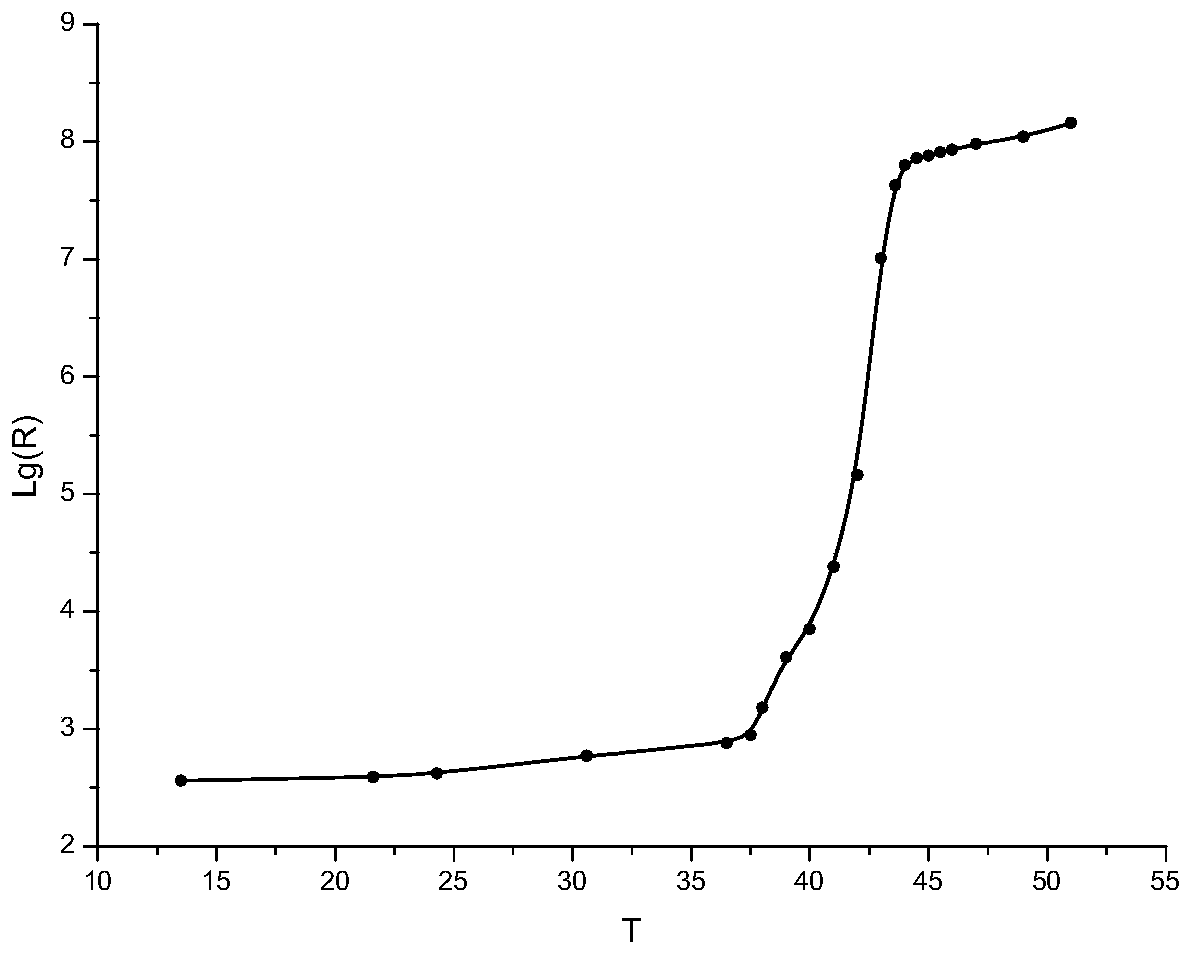

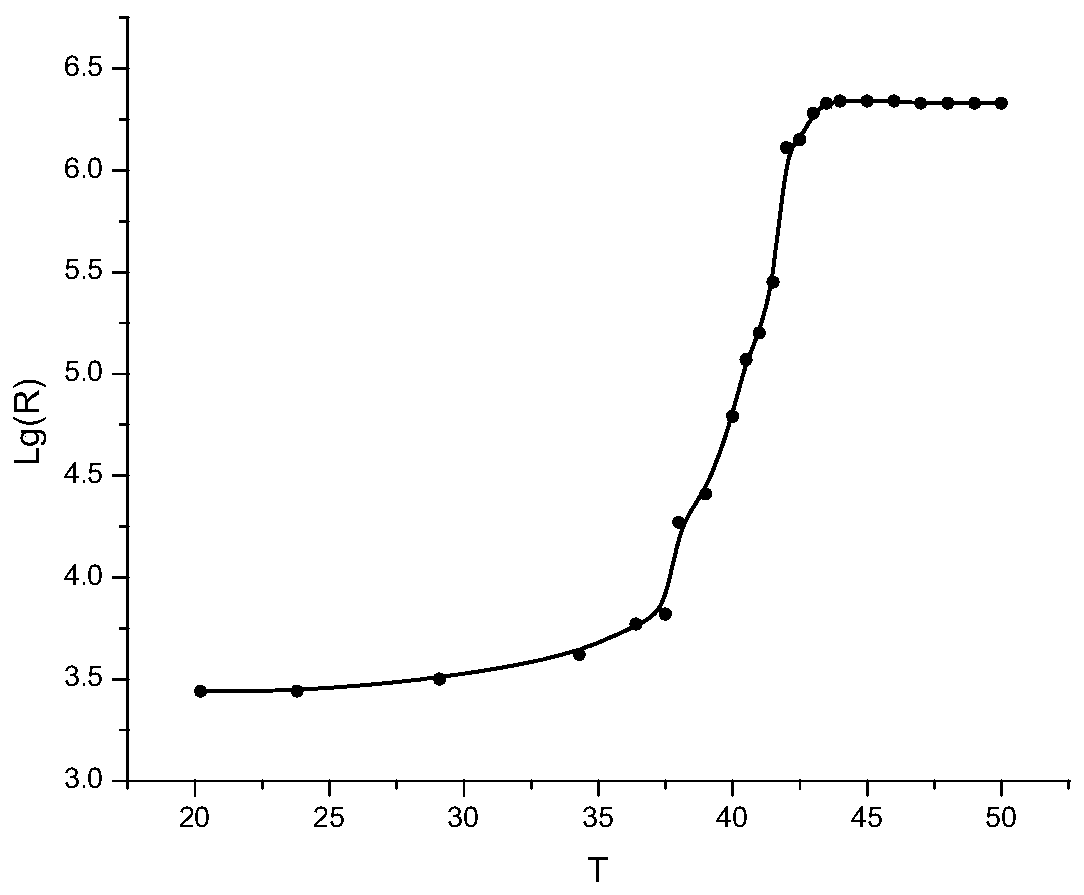

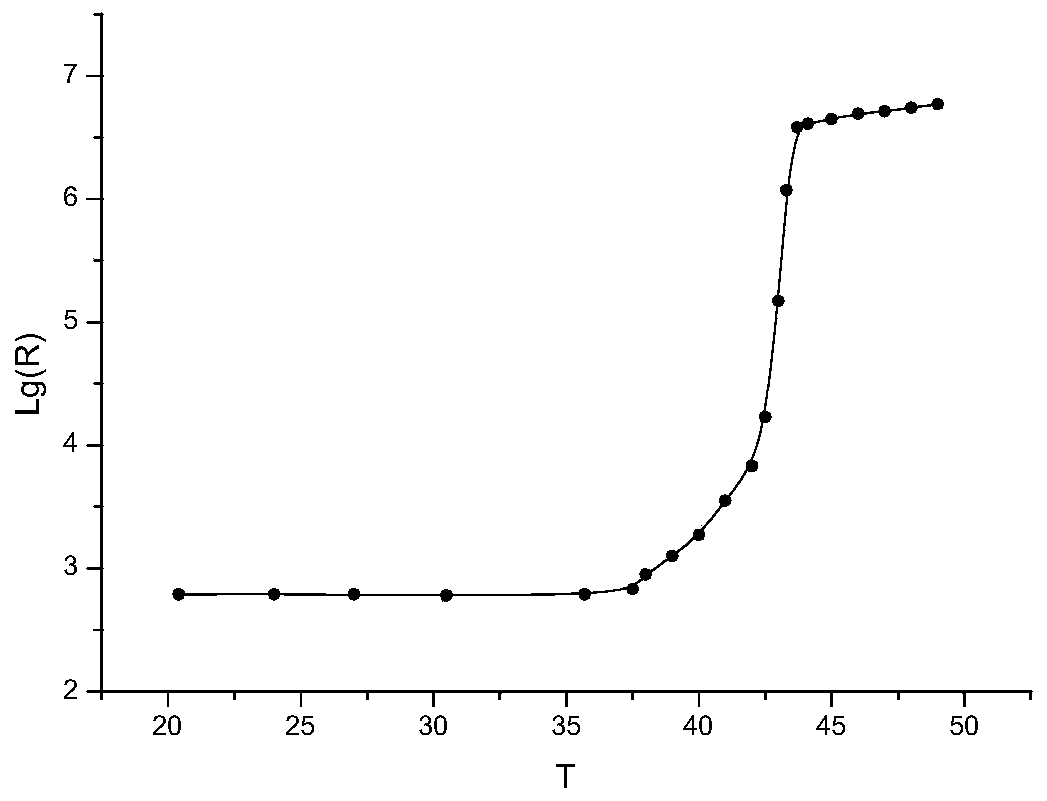

Image

Examples

Embodiment 1

[0030] Raw materials: prepare the materials by their weight (unit / g) according to the formula described in Table 1 (respectively corresponding to the model of raw materials);

[0031] Step 1. Pretreatment of acetylene carbon black: Soak acetylene carbon black with acetone for 24 hours to remove organic substances that may be adsorbed on the surface of acetylene carbon black, filter and distill under reduced pressure to remove acetone; then heat at 100°C for 120 minutes to remove the surface of acetylene carbon black Adsorbed volatile substances;

[0032] Step 2. Mixing and molding of raw materials: Add ethylene-vinyl acetate copolymer (EVA) powder and lauric acid (LA) particles that have been dried in advance into a beaker, pour an appropriate amount (about 50mL) of xylene, and stir in a mechanical Dissolve under heating conditions (temperature about 80°C); after complete dissolution, add acetylene carbon black, mix well, add auxiliary materials (antioxidant 1010, silane coupl...

Embodiment 2

[0036] Raw materials: prepare the materials by their weight (unit / g) according to the formula described in Table 1 (respectively corresponding to the model of raw materials);

[0037]Step 1. Pretreatment of acetylene carbon black: soak acetylene carbon black with acetone for 24 hours to remove organic substances that may be adsorbed on the surface of acetylene carbon black, filter and distill under reduced pressure to remove acetone; then heat at 120°C for 100 minutes to remove the surface of acetylene carbon black Adsorbed volatile substances;

[0038] Step 2. Mixing and molding of raw materials: Add ethylene-vinyl acetate copolymer (EVA) powder and lauric acid (LA) particles that have been dried in advance into a beaker, pour an appropriate amount (about 55mL) of xylene, and stir in a mechanical And dissolve under the condition of heating (temperature about 80°C); after completely dissolving, add other substances (acetylene carbon black, antioxidant AN5057, silane coupling a...

Embodiment 3

[0042] Raw materials: prepare the materials by their weight (unit / g) according to the formula described in Table 1 (respectively corresponding to the model of raw materials);

[0043] Step 1. Pretreatment of acetylene carbon black: Soak acetylene carbon black with acetone for 24 hours to remove organic substances that may be adsorbed on the surface of acetylene carbon black, filter and distill under reduced pressure to remove acetone; then heat at 80°C for 100 minutes to remove the surface of acetylene carbon black Adsorbed volatile substances;

[0044] Step 2. Mixing and molding of raw materials: Add ethylene-vinyl acetate copolymer (EVA) powder and lauric acid (LA) particles that have been dried in advance into a beaker, pour an appropriate amount (about 50mL) of xylene, and stir in a mechanical Dissolve under heating conditions (temperature about 70°C); after completely dissolving, add other substances (acetylene carbon black, antioxidant 168, silane coupling agent KH-560, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com