A kind of epoxidized polyester resin and its preparation method and application

A technology of epoxidizing polyester and polyester resin, which is applied in the direction of polyester coating, powder coating, coating, etc., can solve the problems of corrosion of metal substrates, high cost, limiting the performance and stability of powder coatings, etc., and achieves reduction Effects of cost, good stability and boiling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

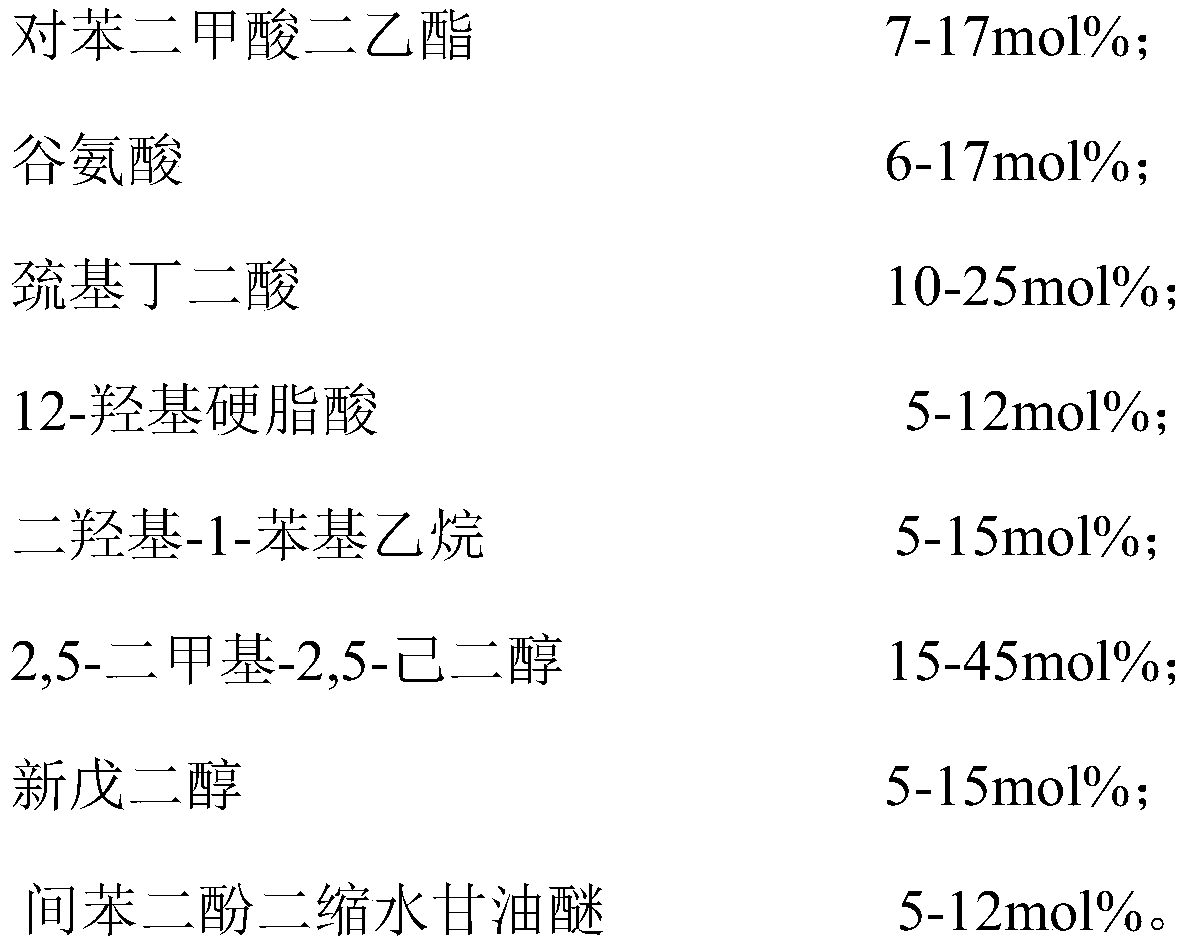

[0026] The epoxidized polyester resin described in the present embodiment, based on the total amount of the epoxidized polyester resin, includes the raw material components in the following molar percentages:

[0027]

[0028] The preparation method of the epoxidized polyester resin described in the present embodiment may further comprise the steps:

[0029] (1) Add a selected amount of diethyl terephthalate, mercaptosuccinic acid and 12-hydroxystearic acid into the mixer, and control the temperature below 130°C for heating and melting;

[0030] (2) Add a selected amount of the dihydroxy-1-phenylethane, 2,5-dimethyl-2,5-hexanediol and neopentyl glycol into the above mixed material, and add a selected amount of the The catalyst is gradually heated up to 180°C under the protection of nitrogen, and a selected amount of glutamic acid is added to mix well, and then the temperature is slowly raised until no obvious distillate is evaporated, and the acid value of the reactant is l...

Embodiment 2

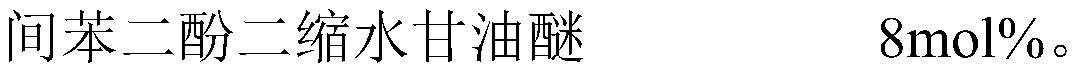

[0035] The epoxidized polyester resin described in the present embodiment, based on the total amount of the epoxidized polyester resin, includes the raw material components in the following molar percentages:

[0036]

[0037]

[0038] The preparation method of the epoxidized polyester resin described in this embodiment is the same as that in Example 1.

[0039] After testing, the acid value of the epoxidized polyester resin obtained in this example is 0.9 mgKOH / g, the epoxy equivalent is 842 g / mol, and the softening point is 101° C.

Embodiment 3

[0041] The epoxidized polyester resin described in the present embodiment, based on the total amount of the epoxidized polyester resin, includes the raw material components in the following molar percentages:

[0042]

[0043] The preparation method of the epoxidized polyester resin described in this embodiment is the same as that in Example 1.

[0044] After testing, the acid value of the epoxidized polyester resin obtained in this example is 0.5 mgKOH / g, the epoxy equivalent is 870 g / mol, and the softening point is 98° C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com