Magnetism insulation piece for wireless charging and preparing method

A technology of wireless charging and magnetic isolation sheet, which is applied in the field of magnetic isolation sheet for wireless charging and its preparation, and can solve the problems of high loss and low Bs of magnetic isolation sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

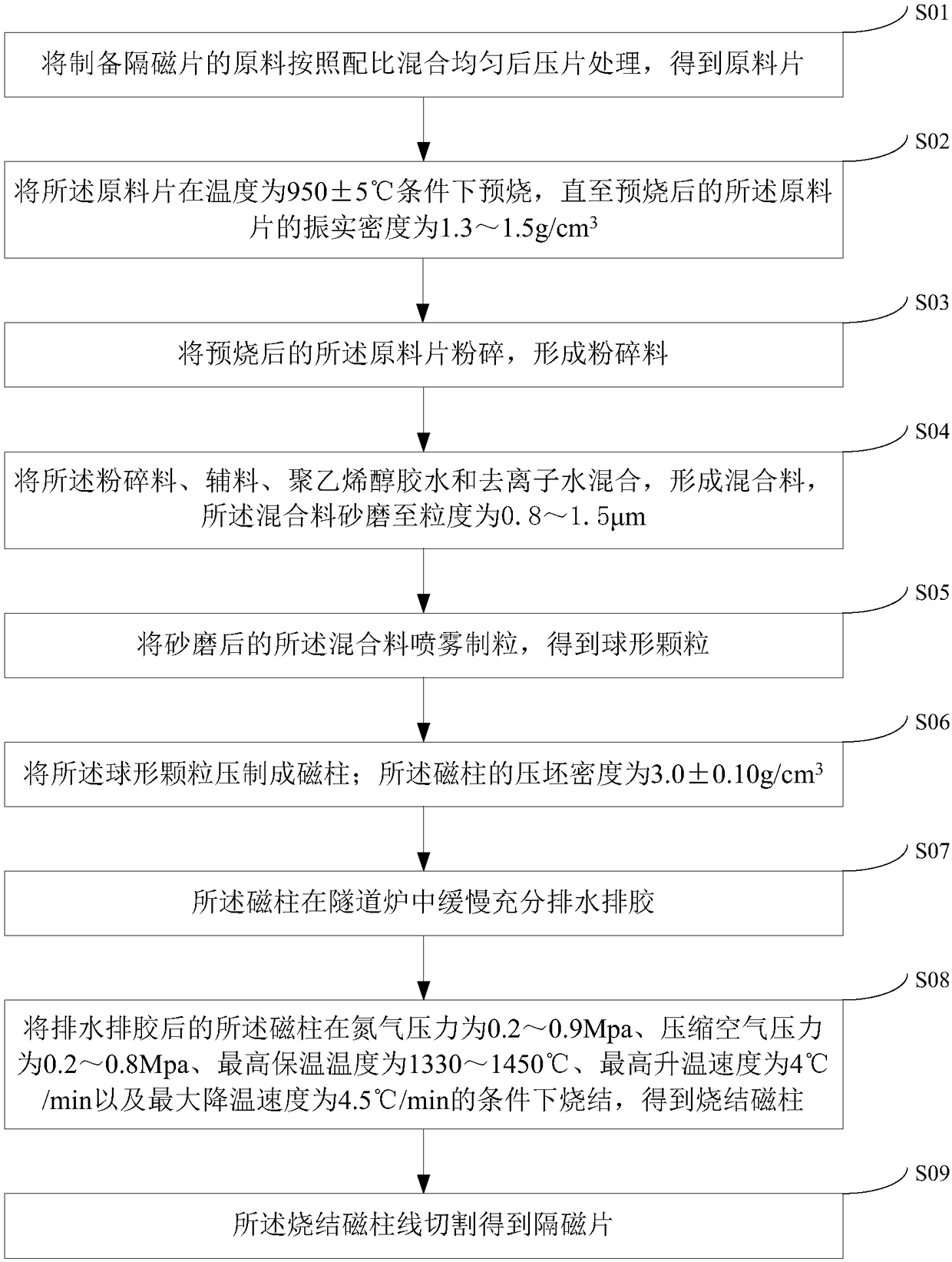

[0041] The embodiment of the present application provides a preparation method of a magnetic isolation sheet for wireless charging, the preparation method comprising:

[0042] S101: The raw materials for preparing the magnetic isolation sheet are Fe according to the mass ratio 2 o 3 69.5%, Mn 3 o 4 23% and ZnO7.5% are uniformly mixed and then tableted to obtain raw material tablets.

[0043] S102: Pre-fire the raw material sheet at a temperature of 950°C until the tap density of the pre-fired raw material sheet is 1.3 g / cm 3 .

[0044] S103: Pulverize the calcined raw material pieces to form a pulverized material.

[0045] S104: Mix crushed materials, auxiliary materials, polyvinyl alcohol glue and deionized water to form a mixture. The rotational speed of the mixture was sand-milled at 2000r / min, the sand-milling time was 180min, and the sand-milled particle size was 0.8μm. The auxiliary materials include calcium carbonate, vanadium pentoxide, niobium pentoxide, elemen...

Embodiment 2

[0053] The embodiment of the present application provides a preparation method of a magnetic isolation sheet for wireless charging, the preparation method comprising:

[0054] S201: The raw materials for preparing the magnetic isolation sheet are Fe according to the mass ratio 2 o 3 69.5%, Mn 3 o 4 23% and ZnO7.5% are uniformly mixed in proportion and then tableted to obtain raw material tablets.

[0055] S202: Pre-fire the raw material sheet at a temperature of 948°C until the tap density of the pre-fired raw material sheet is 1.5 g / cm 3 .

[0056] S203: Pulverize the calcined raw material pieces to form a pulverized material.

[0057] S204: Mix crushed materials, auxiliary materials, polyvinyl alcohol glue and deionized water to form a mixture. The rotation speed of the mixture was 2000r / min, the sanding time was 120min, and the sanding time was 1.4μm. The auxiliary materials include calcium carbonate, vanadium pentoxide, niobium pentoxide, elemental iron and dicobalt...

Embodiment 3

[0065] The embodiment of the present application provides a preparation method of a magnetic isolation sheet for wireless charging, the preparation method comprising:

[0066] S301: The raw materials for preparing the magnetic isolation sheet are Fe according to the mass ratio 2 o 3 65%, MnO26% and ZnO9% are uniformly mixed in proportion and then tableted to obtain raw material tablets.

[0067] S302: Pre-fire the raw material sheet at a temperature of 945°C until the tap density of the pre-fired raw material sheet is 1.3g / cm 3 .

[0068] S303: Pulverize the calcined raw material pieces to form a pulverized material.

[0069] S304: Mix crushed materials, auxiliary materials, polyvinyl alcohol glue and deionized water to form a mixture. The rotational speed of the mixture was sand-milled at 2000r / min, the sand-milling time was 90min, and the sand-milled particle size was 1.2μm. The auxiliary materials include calcium carbonate, vanadium pentoxide, niobium pentoxide, elemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com