A complete set of welding equipment for high-pressure helium filling and laser welding of nuclear fuel rod cladding

A nuclear fuel rod, laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve problems such as large consumption, and achieve the effect of small helium filling, low energy consumption, and low helium consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail below in conjunction with accompanying drawing:

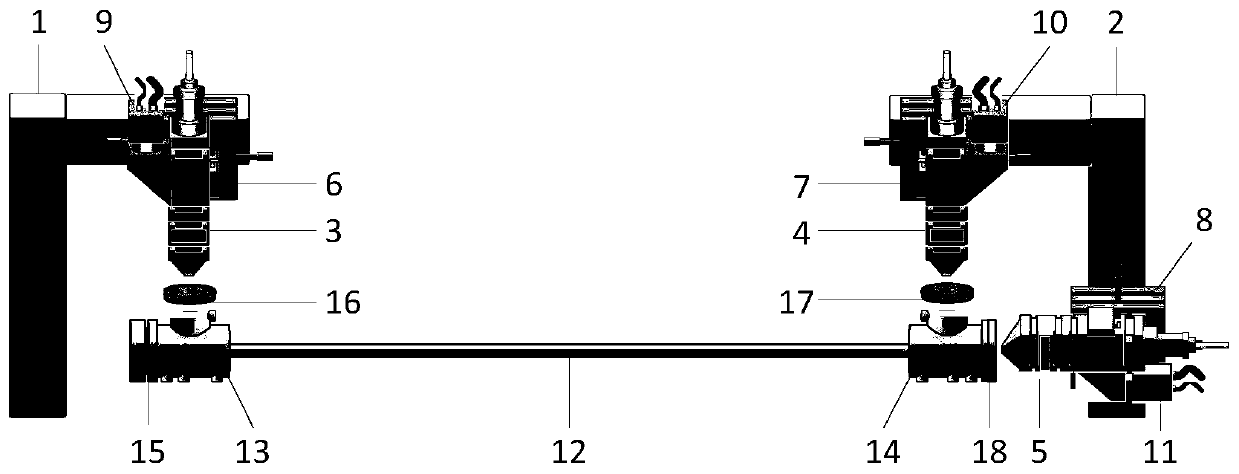

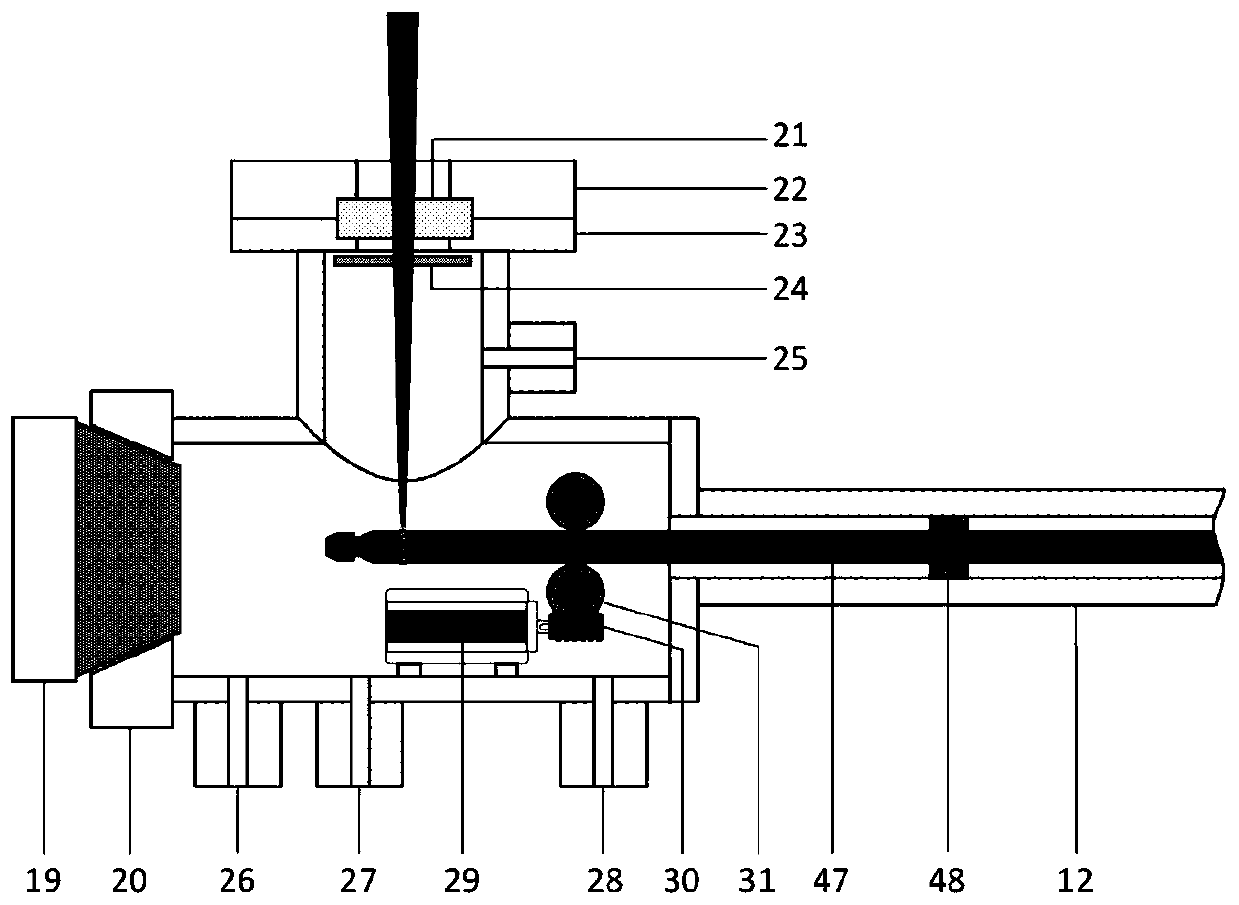

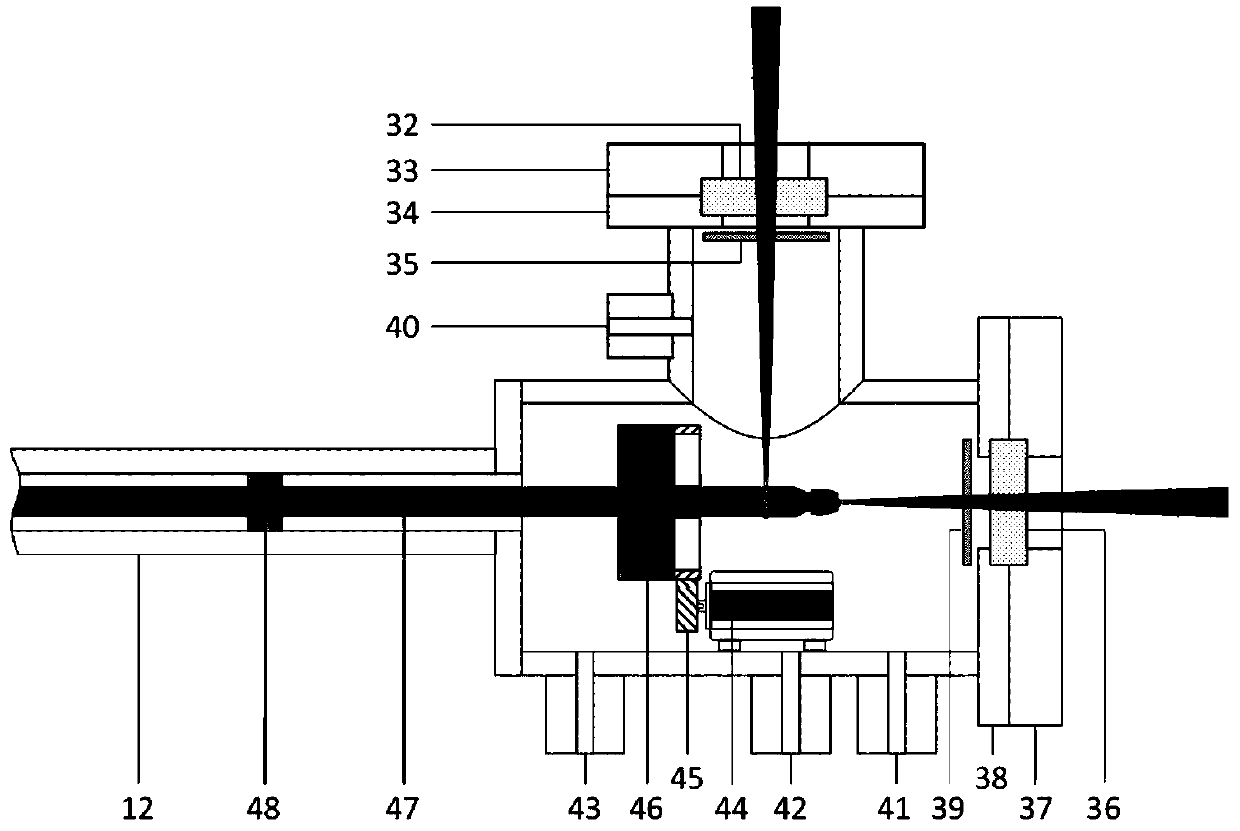

[0033] refer to figure 1 , figure 2 and image 3, the nuclear fuel rod cladding high-pressure helium filling and laser welding complete set of welding equipment according to the present invention includes a first welding chamber end 13, a plug valve head 19, a plug valve seat 20, a second welding chamber end 14, and a welding chamber neck 12. The first laser welding head 3, the second laser welding head 4 and the third laser welding head 5; the end surface of the end 13 of the first welding chamber is provided with an upper and lower material opening 15, and the plug valve head 19 is fixed on the At the loading and unloading port 15, the side of the first welding chamber end 13 is provided with a first laser incident window 16, a first air inlet 25 and a vacuum pump interface 26, and the first welding chamber end 13 is equipped with a transfer roller 31 and a The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com