Automatic welding device for circular seam of steel pipe of pressure shaft and construction method

A technology for automatic welding and pressure steel pipes, applied to welding equipment, welding accessories, electrode support devices, etc., to achieve the effects of simplifying the construction process, improving welding efficiency, and saving engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

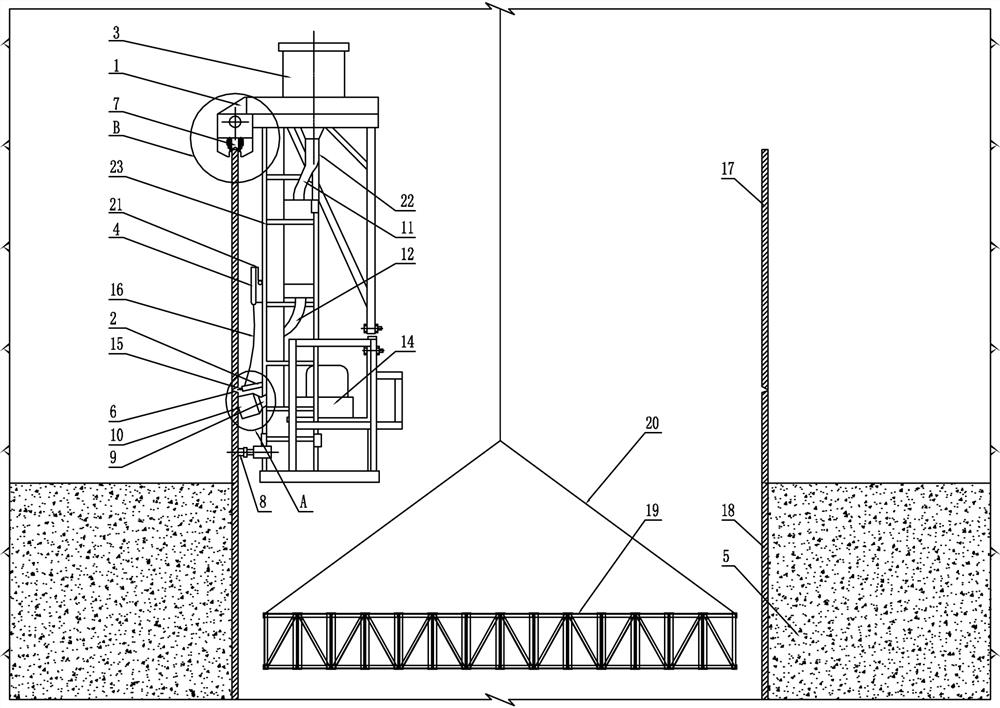

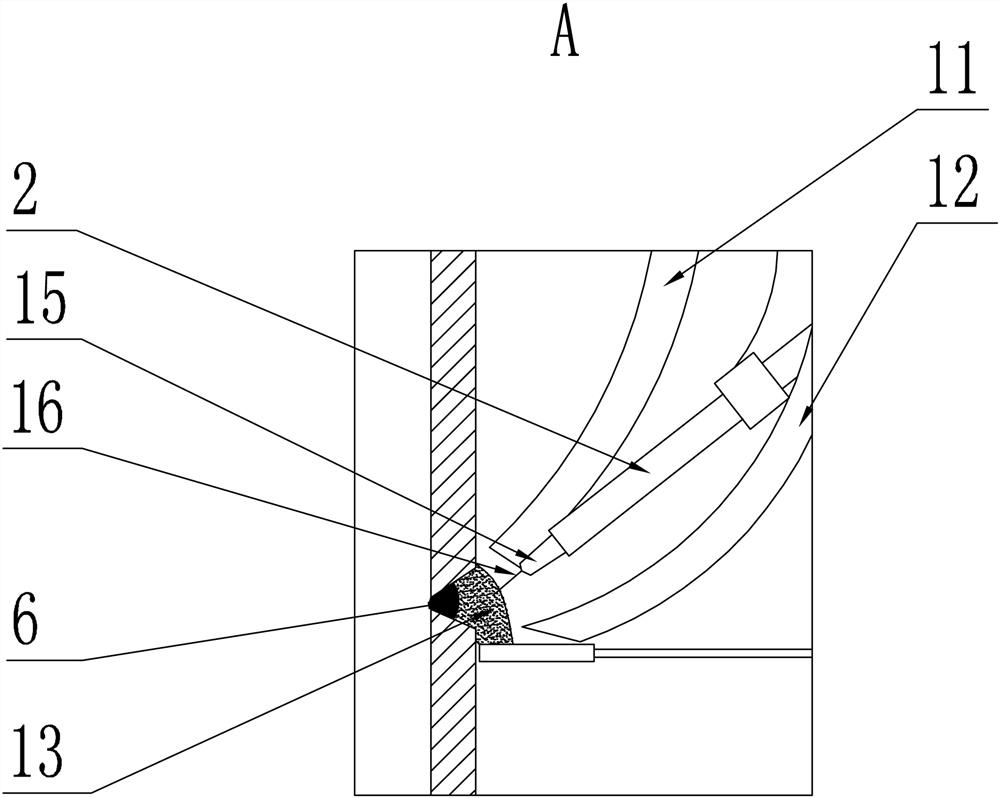

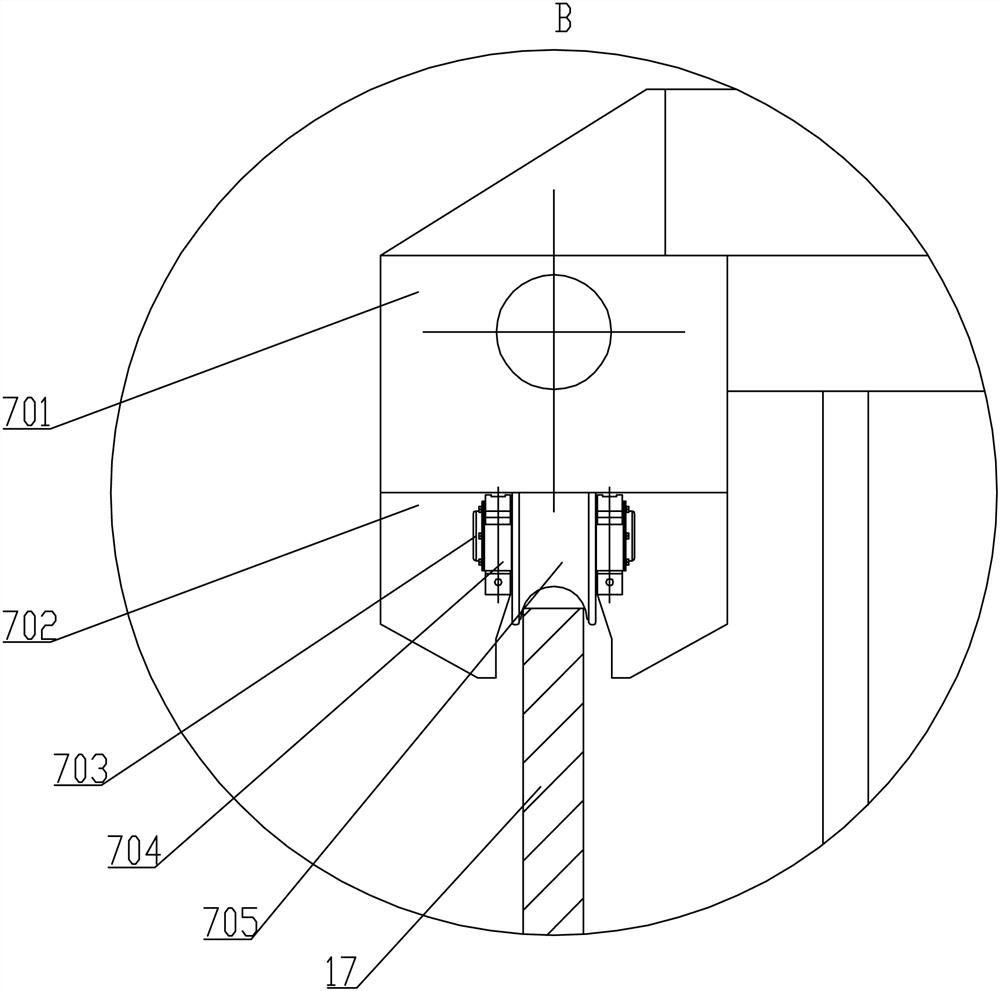

[0056] see Figure 1-10 , the automatic welding device for the girth seam of the pressure shaft steel pipe, comprising a walking frame structure 23 for carrying the submerged arc welding automatic welding system 21; The welding walking system 1 that moves circumferentially on the circular weld 6; the automatic submerged arc welding system 21 is connected to the flux delivery and recovery system 22 installed on the welding walking frame structure 17; the automatic submerged arc welding system 21. The welding walking system 1 and the flux feeding and recycling system 22 are connected with the automatic control system. The automatic welding device is simple in structure and easy to use. It can not only improve the working environment, reduce labor intensity, but also improve welding efficiency and save engineering costs. It can be used for fully automatic welding of steel pipe ring seams in pressure shafts. In the specific welding process, the entire walking frame structure 23 i...

Embodiment 2

[0065] see Figure 4-10 A method for constructing a pressure pipe shaft of a hydropower station by using an automatic welding device for the ring seam of a pressure shaft steel pipe comprises the following steps:

[0066] Step 1, automatic welding device assembly: according to the basic size of the penstock to be installed, make and select the specific model and size of the automatic welding device to be used in the subsequent welding process on site;

[0067] Step 2: Installation of the bottom section steel pipe: the installation of the first installed steel pipe 18 is carried out in the vertical shaft;

[0068] Step 3: Fixing of the bottom steel pipe: after the installation of the installed steel pipe 18 is completed, fill backfill concrete 5 between the installed steel pipe 18 and the shaft, and fix the installed steel pipe 18;

[0069] Step 4: docking of the steel pipes in the upper section: after the installed steel pipes 18 are fixed, the steel pipes 17 to be installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com