Porous magnesium manganate and preparation method and application thereof

A technology of porous magnesium manganate and magnesium nitrate is applied in the field of porous magnesium manganate and its preparation to achieve the effects of improving water quality and promoting sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of porous magnesium manganate, the preparation method of described porous magnesium manganate is as follows:

[0031] (1) According to the raw material molar ratio of magnesium nitrate: manganese nitrate: citric acid = 1:1:2, weigh 1073.7mg (3mmol) manganese nitrate solution with a mass fraction of 50%, 769.2mg (3mmol) magnesium nitrate hexahydrate, 1260.8 mg (6mmol) citric acid monohydrate, placed in a 100mL beaker. Add an appropriate amount of pure water to just enough to dissolve all the solids to form a uniform solution.

[0032] (2) Add 25% (w / w) ammonia water dropwise to the above solution, stir, and stop adding ammonia water when the pH value is adjusted to 5.0-6.0. Place the beaker in an 80°C water bath and stir for 2h, then transfer to 80°C o C oven for further drying.

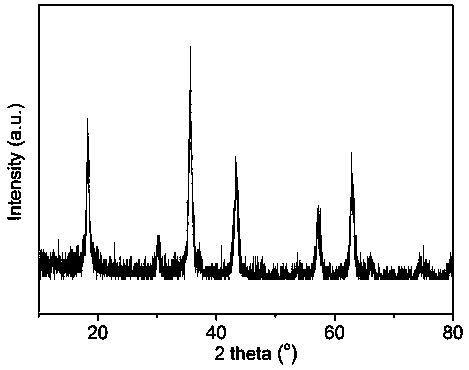

[0033] (3) The dry gel is calcined in a muffle furnace, and after a calcination time of 2 hours at a calcination temperature of 450°C, it is cooled and ground to obtain a brown-black ...

Embodiment 2

[0036] A kind of porous magnesium manganate, the preparation method of described porous magnesium manganate is as follows:

[0037] (1) According to the molar ratio of raw materials magnesium nitrate: manganese nitrate: citric acid = 1.0: 1.05: 3, respectively weigh 1073.7mg (3mmol) manganese nitrate solution with a mass fraction of 50%, 807.7mg (3.15mmol) magnesium nitrate hexahydrate, 1891.2mg (9mmol) of citric acid monohydrate was placed in a 100mL beaker. Add an appropriate amount of pure water to just enough to dissolve all the solids to form a uniform solution.

[0038] (2) Add 25% (w / w) ammonia water dropwise to the above solution, stir, and stop adding ammonia water when the pH value is adjusted to 9.0-10.0. The beaker was stirred in a 60°C water bath for 6h, and then transferred to an 80°C oven for further drying.

[0039] (3) The xerogel is calcined in a muffle furnace. After a calcination time of 1 h at a calcination temperature of 550° C., it is cooled and ground...

Embodiment 3

[0041] A kind of porous magnesium manganate, the preparation method of described porous magnesium manganate is as follows:

[0042] (1) According to the molar ratio of raw materials, magnesium nitrate: manganese nitrate: or ethylenediaminetetraacetic acid = 1.05: 1: 0.5, respectively weigh 1127.4mg (3.15mmol) manganese nitrate solution with a mass fraction of 50%, 769.2mg (3mmol) six Magnesium nitrate hydrate and 438.4 mg (1.5 mmol) citric acid monohydrate were placed in a 100 mL beaker. Add an appropriate amount of pure water to just enough to dissolve all the solids to form a uniform solution.

[0043] (2) Add 25% (w / w) ammonia water dropwise to the above solution, stir, and stop adding ammonia water when the pH value is adjusted to 10.0-12.0. Place the beaker in a 70°C water bath and stir for 4h, then transfer to 80°C o C oven for further drying.

[0044] (3) The dry gel is calcined in a muffle furnace, and after a calcination time of 10 hours at a calcination temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com