Waterproof and moisture-permeable multifunctional polyurethane thin film glove

A polyurethane film, waterproof and moisture-permeable technology, applied in gloves, protective clothing, clothing, etc., can solve the problems of low consumer acceptance, ugly appearance, and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

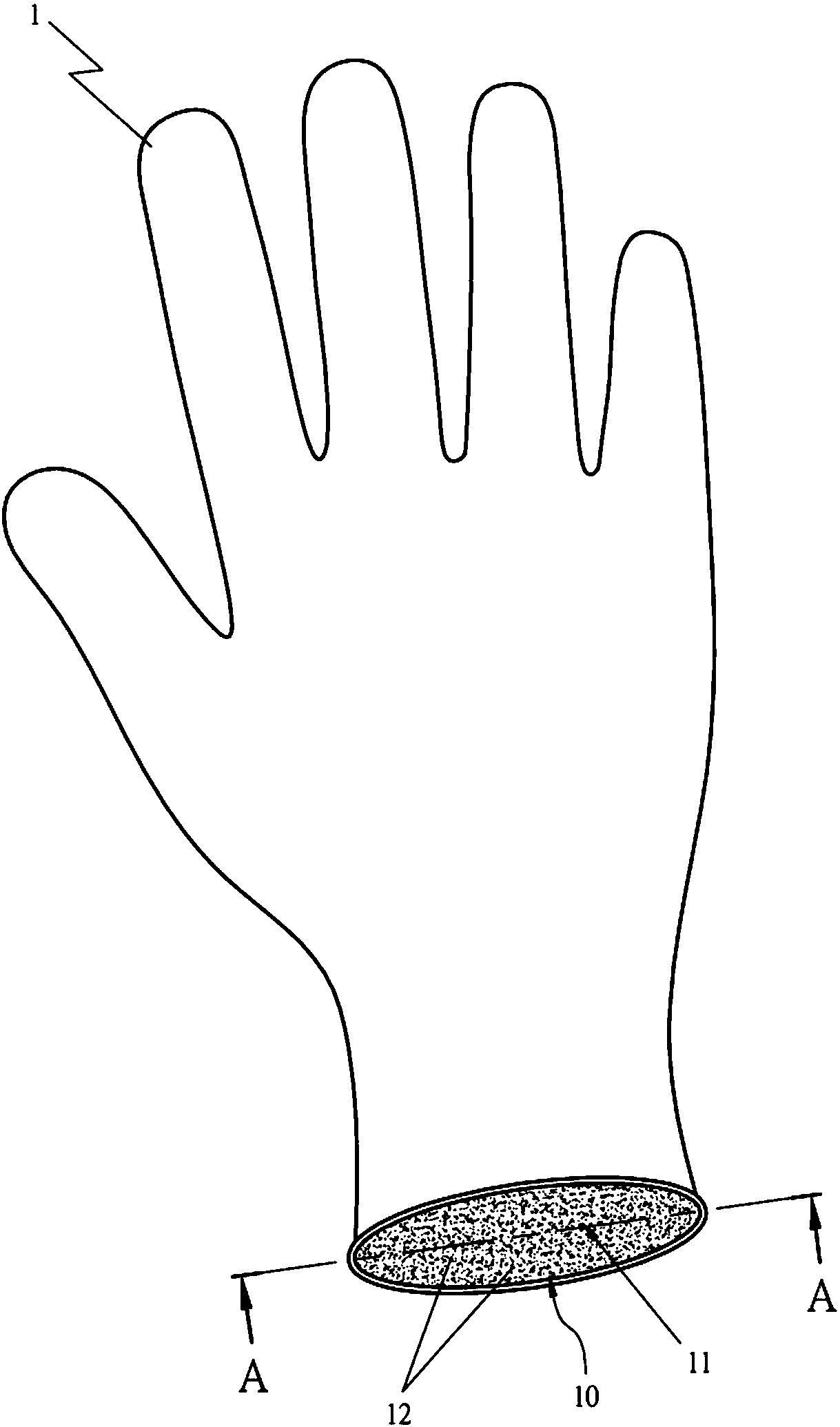

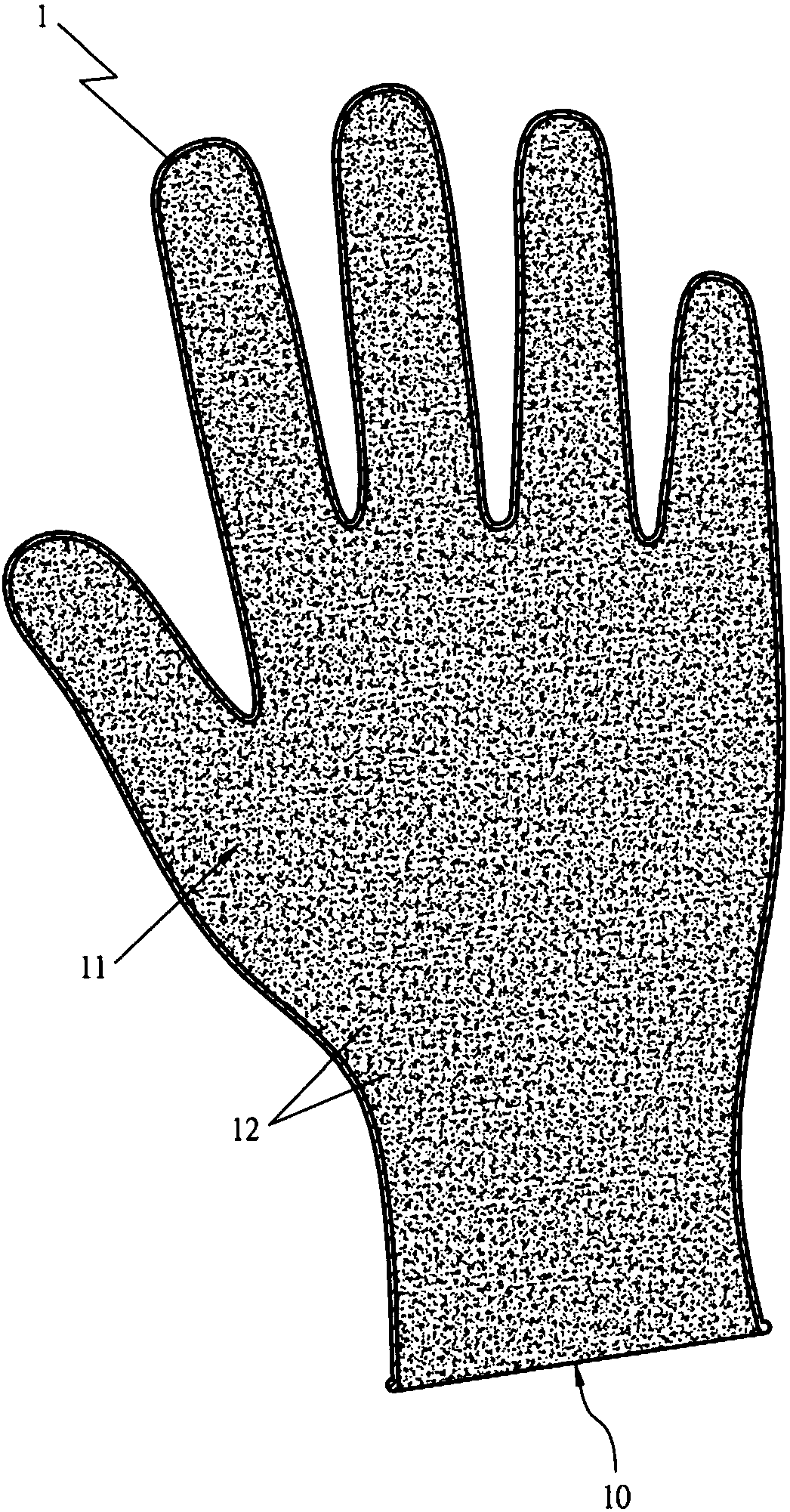

[0019] In order to further understand the present invention, the embodiment of the best waterproof and moisture-permeable multifunctional polyurethane film cover is as follows figure 1 and 2 As shown, at least include:

[0020] Cover body 1, which is a film cover made of polyurethane (PU) raw materials containing polyethylene glycol (PEG) structure integrally formed, because polyethylene glycol has the characteristics of hydrophilic and moisture permeability The polyurethane raw material of alcohol makes the waterproof polyurethane cover 1 have a high moisture permeability effect, and can simultaneously maintain the good stretching, tear resistance, elasticity and other characteristics of the polyurethane material, and the polyurethane material is a decomposable material, so it can be used The cover body 1 achieves the effect of environmental protection. Such as figure 1 As shown, the aforementioned cover body 1 is provided with an opening 10, and an accommodating groove 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com