Gun-pressed elastic ground wire

A grounding wire and elastic technology, which is applied in the field of sheet metal welding, can solve the problems of small contact point, output current attenuation, and the ground wire is not easy to weld firmly, so as to achieve good contact, reduce output impedance, and improve the welding success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

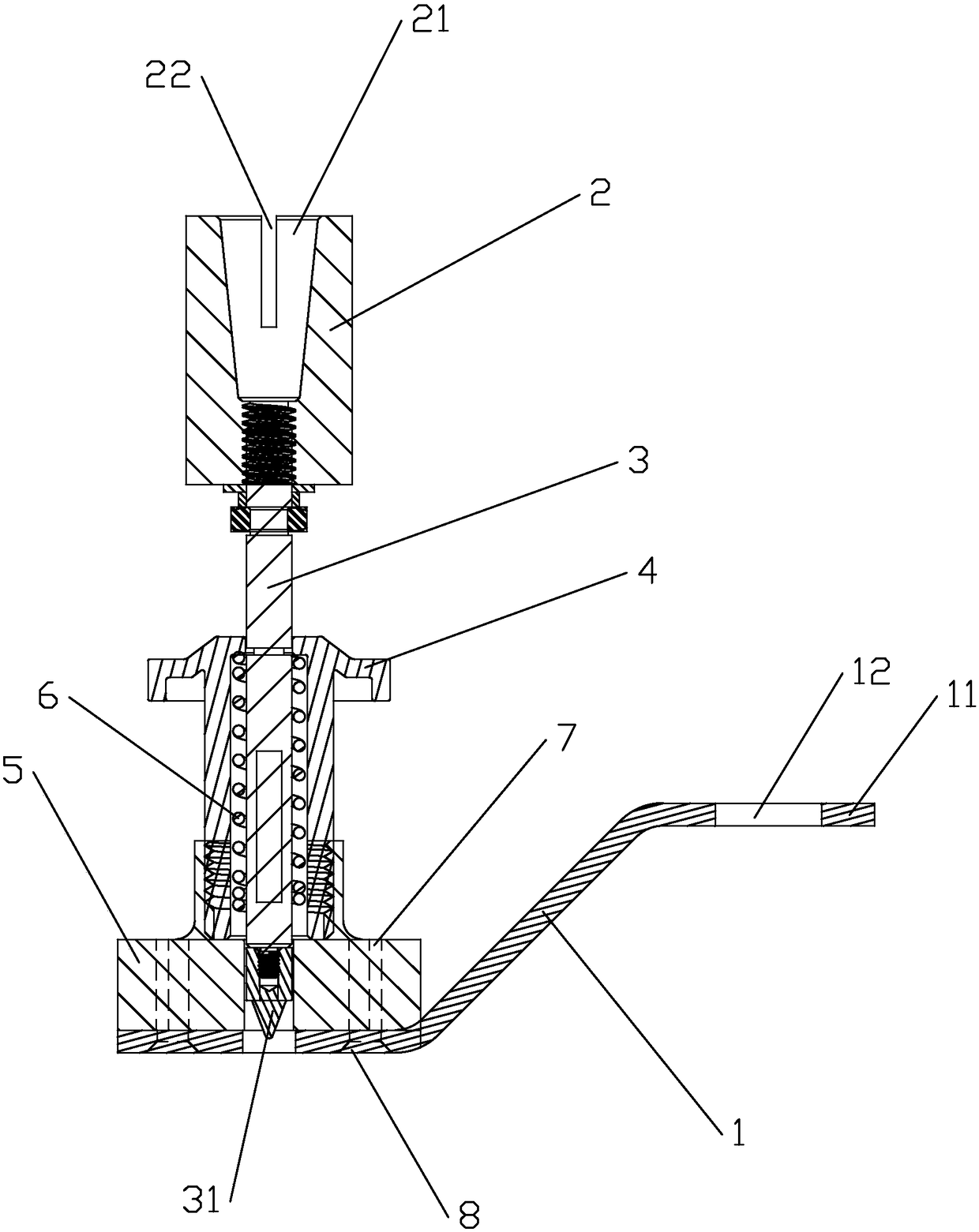

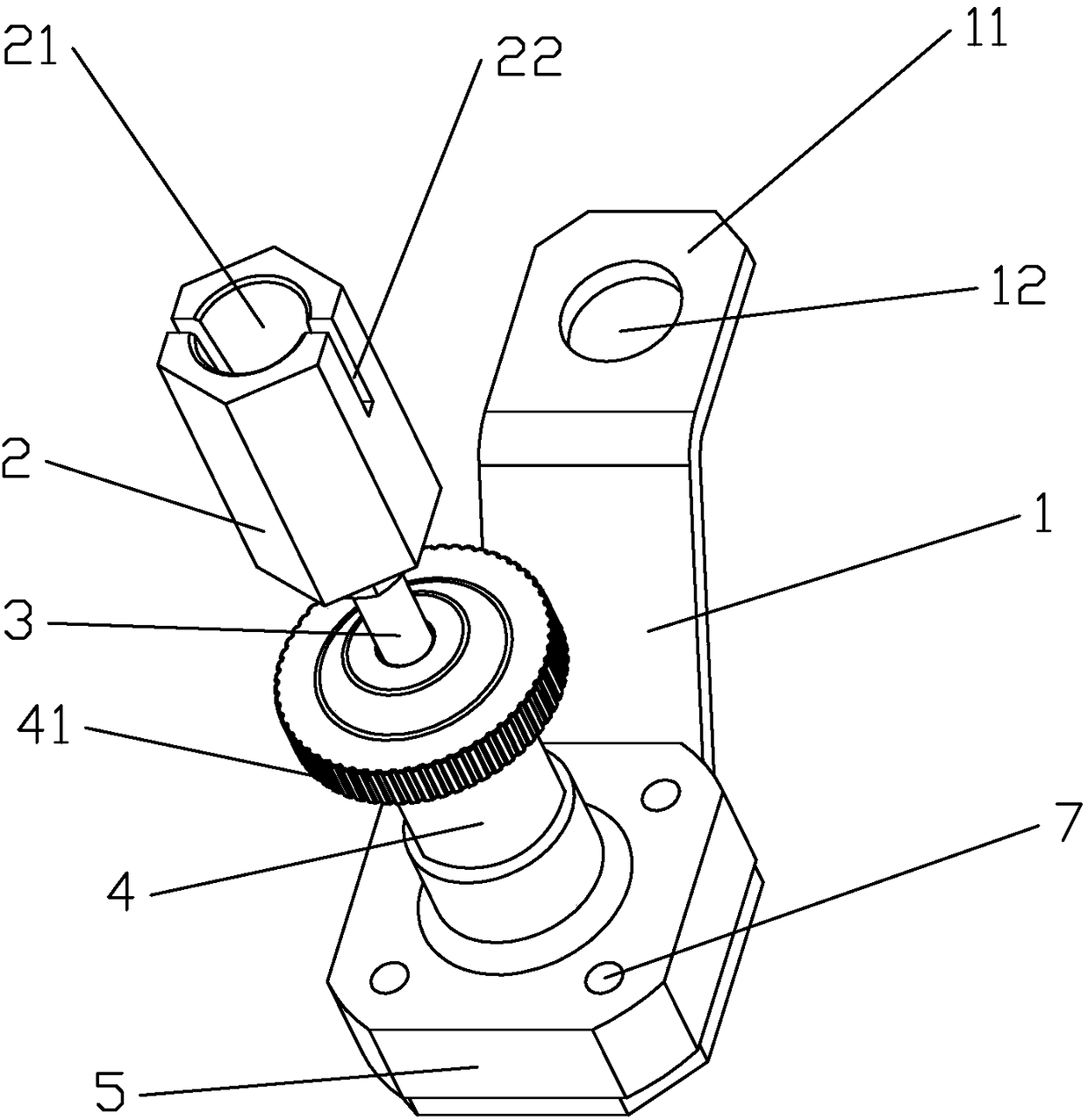

[0021] Such as figure 1 and figure 2 As shown, one of the embodiments provided by the present invention, the gun pressure elastic grounding wire, includes a welding unit and a grounding unit, and the welding unit includes a depressible transfer part connected to the welding gun and a welding connection with the sheet metal welding. part, the transition part is provided with a cavity 21 and an opening groove 22, the welding part is provided through the grounding unit, and an elastic element is provided between the welding part and the grounding unit, so that The welding part has an extended state and a retracted state; the grounding unit includes an insulating component movably sleeved outside the welding part, and a ground wire base 1 in contact with the sheet metal.

[0022] The adapter part is a metal adapter 2, and the middle part is provided with an inverted tapered concave cavity 21, which can be matched with welding and drawing tools of different diameters, and an open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com