Preparation method of three-dimensional hollow selenium nickel sulfide nano-frame catalyst

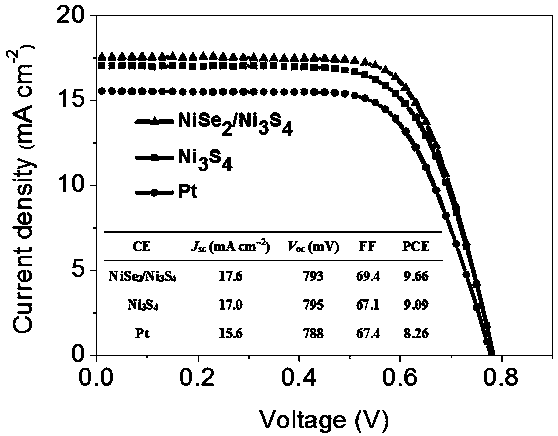

A three-dimensional hollow, nickel sulfide technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as poor adhesion and short circuit of DSSCs, and achieve stability Good performance, small size, cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

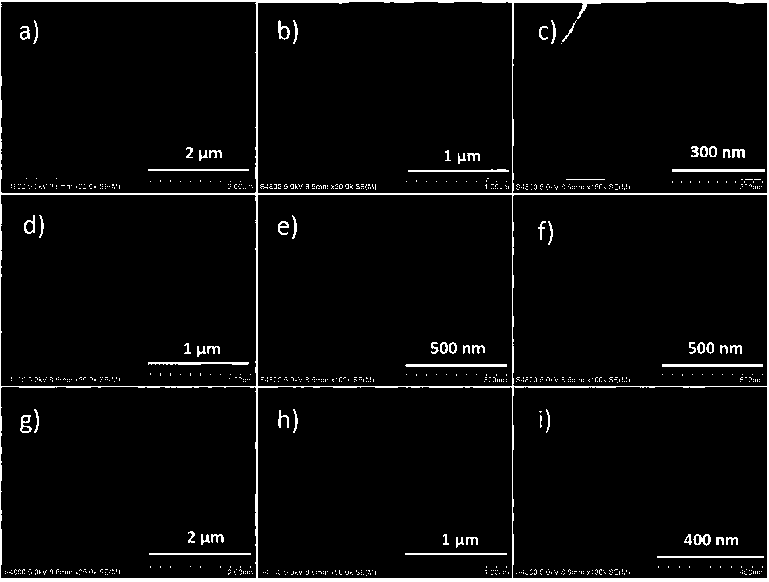

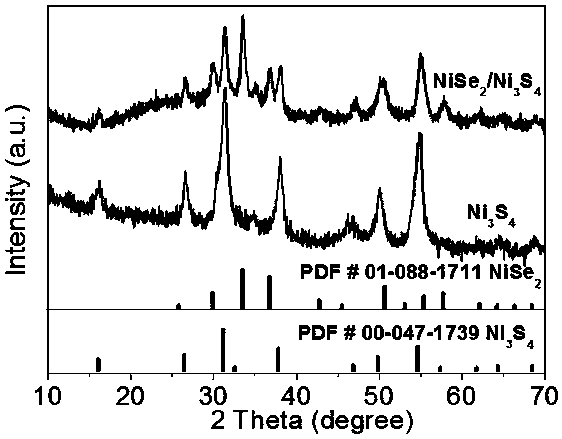

[0025] Disperse 3 mmol cobalt nitrate hexahydrate and 4.5 mmol sodium citrate dihydrate in 100 mL deionized water to form component A, and disperse 2 mmol potassium cobaltcyanide in 100 mL deionized water to form component B. Component B and component B were mixed and stirred for 1 min, then allowed to stand for 18 h, and dried by centrifugation to obtain blue Ni-Co PBA. Disperse 50 mg of Ni-Co PBA and 250 mg of sodium sulfide nonahydrate in 30 mL of absolute ethanol and 10 mL of deionized water with magnetic stirring, respectively. After mixing, continue to stir for 15 min, and seal them in a 100 mL polytetrafluoroethylene-lined container. In a high-pressure reactor, the solvothermal reaction was carried out at 120 °C for 6 h, and the three-dimensional hollow nickel sulfide nanoframes were obtained by centrifugal drying. Then 15 mg of the above-mentioned nickel sulfide nanoframes and 30 mg of selenium powder were magnetically stirred and dispersed in 50 mL of deionized water,...

Embodiment 2

[0027]Disperse 3 mmol cobalt nitrate hexahydrate and 4.5 mmol sodium citrate dihydrate in 100 mL deionized water to form component A, and disperse 2 mmol potassium cobaltcyanide in 100 mL deionized water to form component B. Component B and component B were mixed and stirred for 1 min, then allowed to stand for 18 h, and dried by centrifugation to obtain blue Ni-Co PBA. Disperse 50 mg of Ni-Co PBA and 250 mg of sodium sulfide nonahydrate in 30 mL of absolute ethanol and 10 mL of deionized water with magnetic stirring, respectively. After mixing, continue to stir for 15 min, and seal them in a 100 mL polytetrafluoroethylene-lined container. In a high-pressure reactor, solvothermal reaction was carried out at 140 °C for 6 h, and the three-dimensional hollow nickel sulfide nanoframes were obtained by centrifugal drying. Then 15 mg of the above-mentioned nickel sulfide nanoframes and 30 mg of selenium powder were magnetically stirred and dispersed in 50 mL of deionized water, and ...

Embodiment 3

[0029] Disperse 3 mmol cobalt nitrate hexahydrate and 4.5 mmol sodium citrate dihydrate in 100 mL deionized water to form component A, and disperse 2 mmol potassium cobaltcyanide in 100 mL deionized water to form component B. Component B and component B were mixed and stirred for 1 min, then allowed to stand for 18 h, and dried by centrifugation to obtain blue Ni-Co PBA. Disperse 50 mg of Ni-Co PBA and 250 mg of sodium sulfide nonahydrate in 30 mL of absolute ethanol and 10 mL of deionized water with magnetic stirring, respectively. After mixing, continue to stir for 15 min, and seal them in a 100 mL polytetrafluoroethylene-lined container. In a high-pressure reactor, solvothermal reaction was carried out at 160 °C for 6 h, and the three-dimensional hollow nickel sulfide nanoframes were obtained by centrifugal drying. Then 15 mg of the above-mentioned nickel sulfide nanoframes and 30 mg of selenium powder were magnetically stirred and dispersed in 50 mL of deionized water, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com