Additive manufacturing on-line detection and repairing method

A technology of additive manufacturing and repair method, which is applied in the fields of laser remelting process to eliminate specified defects, closed-loop control, additive manufacturing online inspection and repair, and can solve the problems that affect the mechanical properties and service life of additive manufacturing components, and the cumbersome laser inspection steps , long scanning time at the slice level, etc., to avoid the inconvenience of detection and repair, the detection speed is fast, and the quality of the product is guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

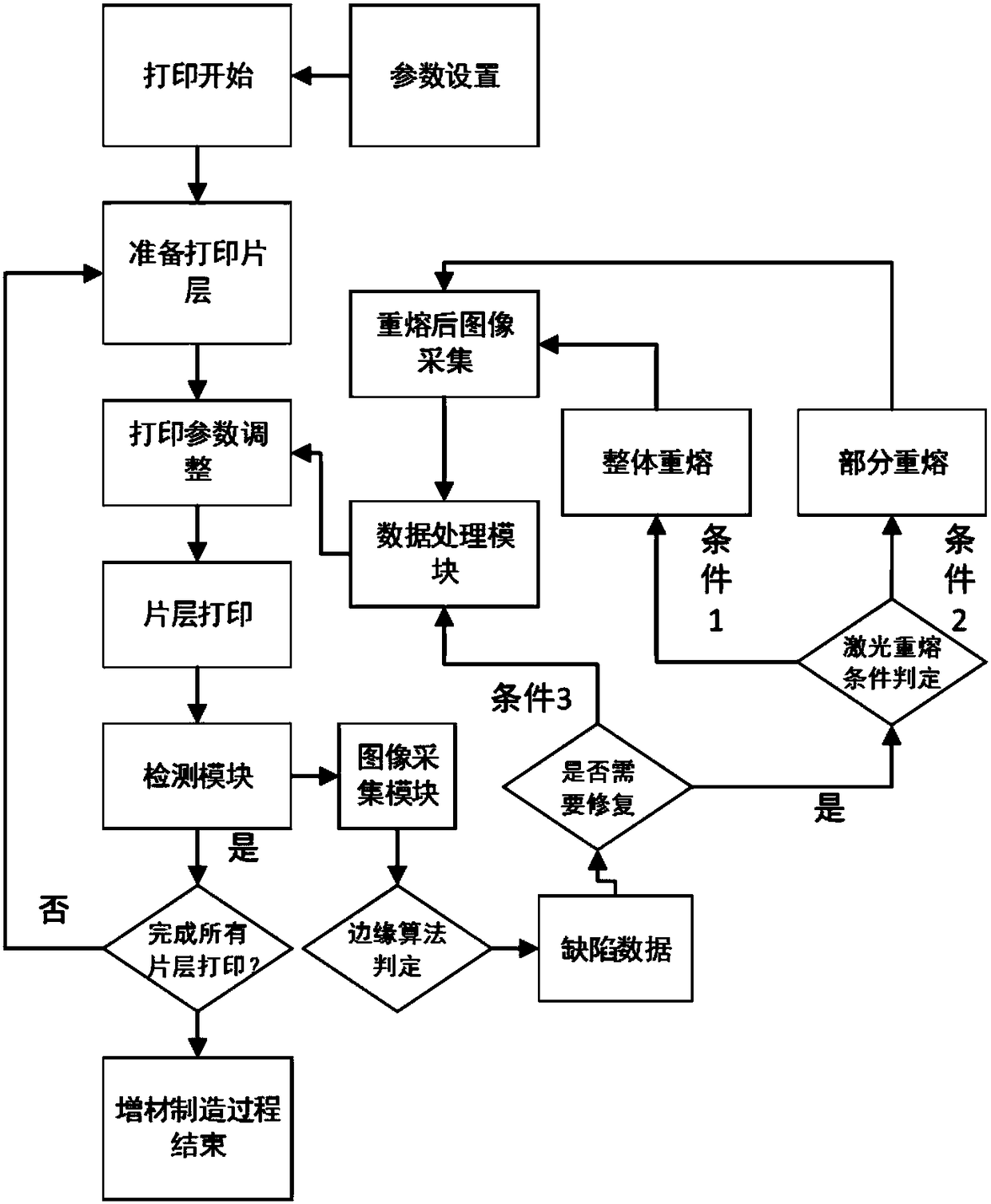

[0037] Specific embodiments: the present invention is a method for combining detection and repair, comprising the following steps:

[0038] Step 1: Set the parameters of the defect detection system: set the maximum allowable defect area S before processing max =1mm 2 , the negligible defect area S min =0.1mm 2 , the maximum number of single-layer defects N max =10 x , set the maximum allowable defect area S max The number threshold M=3, the edge point diameter threshold C=0.5;

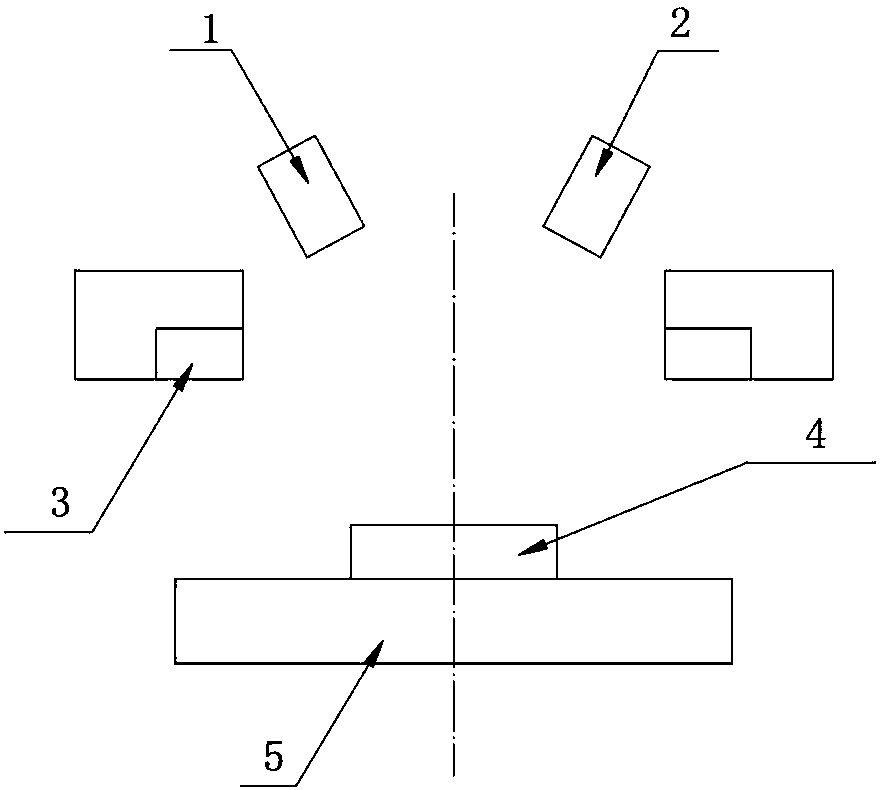

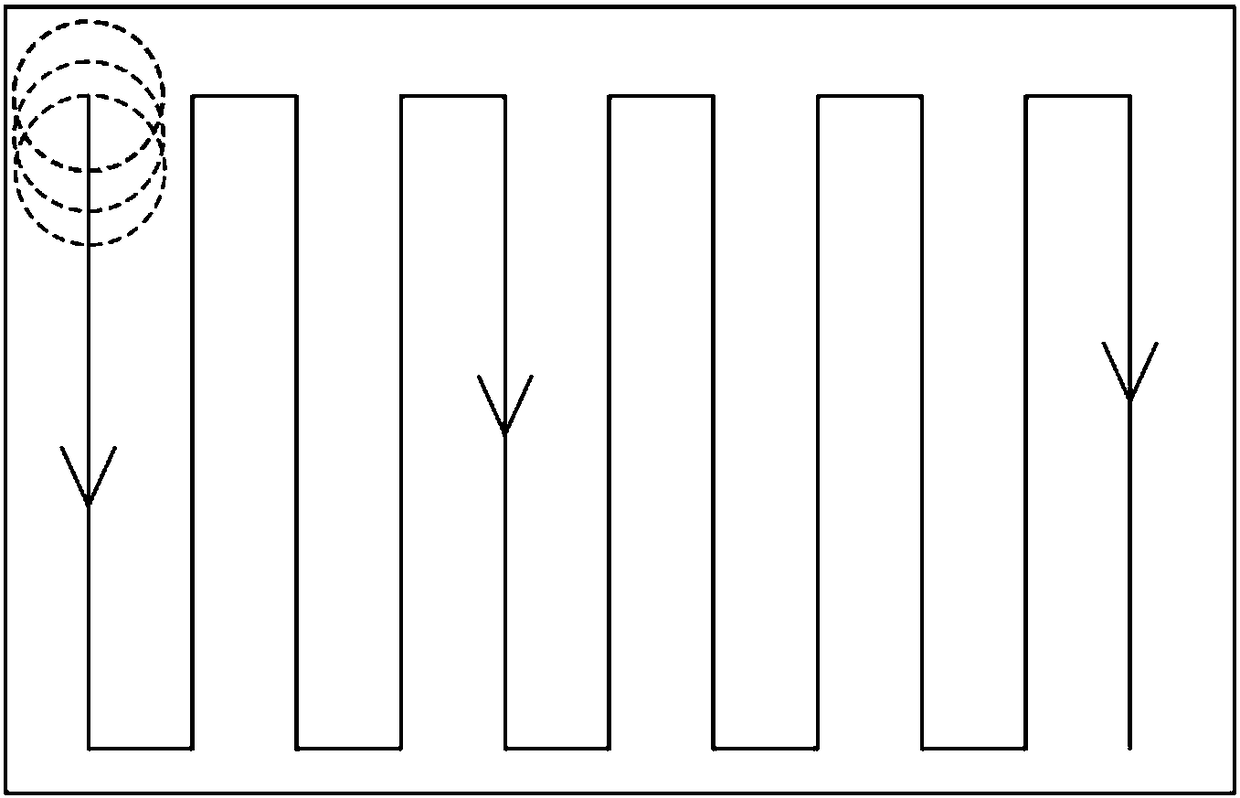

[0039] Step 2: The additive manufacturing equipment accepts the processing command to process the current layer. After the processing of the layer, the additive manufacturing equipment accepts the pause command, the ring light is turned on, the camera module moves through the guide rail to a suitable position above the workpiece, and the image acquisition module Send a starting pulse to the camera module, the camera module starts slice image scanning, and outputs the data to the image acquisition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com