A kind of use waste PET bottle to prepare UV curing polyurethane acrylate and preparation method thereof

A polyurethane acrylate, waste technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of unfavorable environment, high reaction temperature, degradation of paint film performance, etc., to relieve huge pressure, high stability, adhesion high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

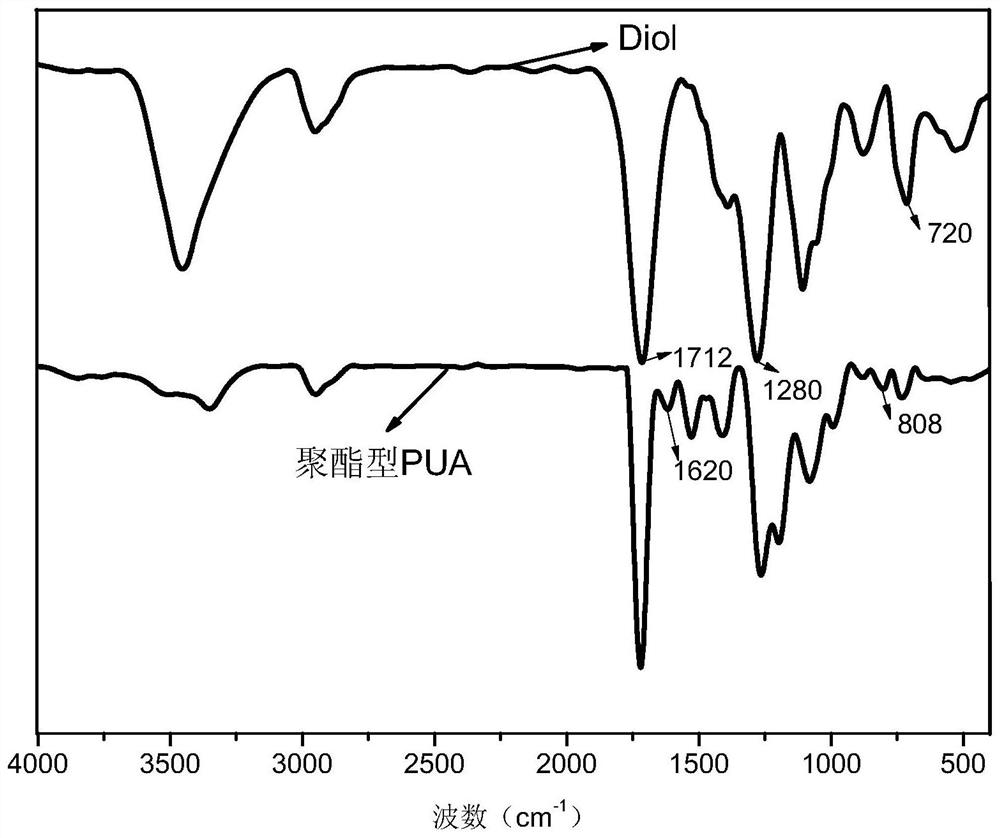

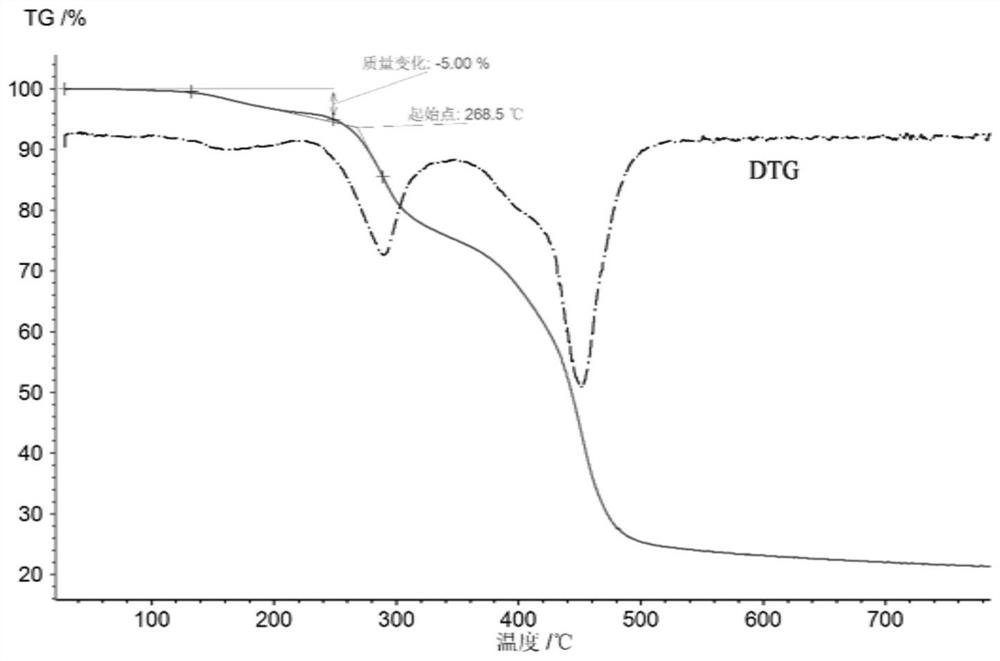

Method used

Image

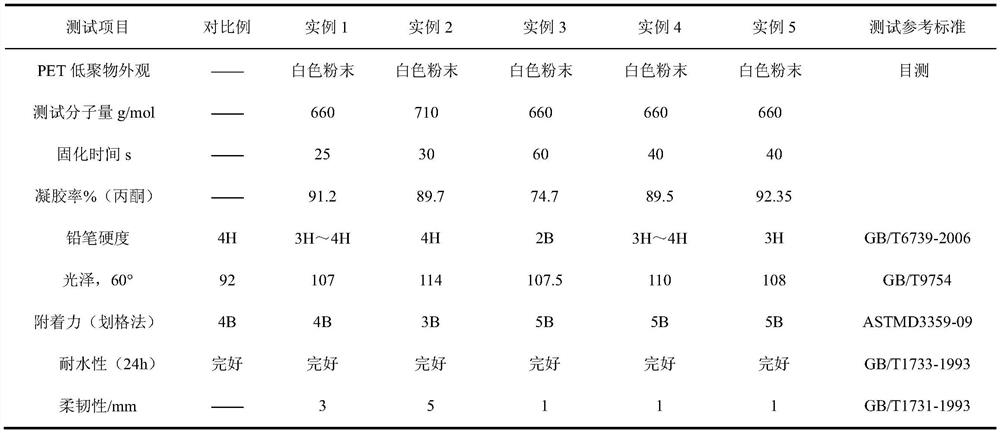

Examples

Embodiment 1

[0029](1) Alcoholysis of waste PET: cut the waste PET bottle into small pieces, after washing treatment, take 50g PET fragments, 64.65g ethylene glycol, 0.48g zinc acetate, and add them to a four-necked flask with mechanical stirring, condensation device and thermometer In an atmosphere of nitrogen, heating to 190°C and reacting for 1.5 hours to split the PET long chain into hydroxyl-terminated short-chain diols. Among them, the molecular weight of the PET repeating unit is 192 g / mol.

[0030](2) Step (1) After the reaction is completed, a light yellow translucent liquid is obtained, and the alcoholysis solution is suction filtered while it is hot, and the filtrate obtained is ultrasonically washed with deionized hot water at 80°C, and then quickly placed in a high-speed centrifuge at 4000 rpm Centrifuge for 6 minutes to obtain the water-insoluble alcoholysis product. Take the precipitate and repeat the washing and centrifugation operation 3 times. Place the alcoholysis product in a va...

Embodiment 2

[0034](1) Alcoholysis of waste PET: cut the waste PET bottle into small pieces, after washing, take 50g PET fragments, 48.49g ethylene glycol, 0.48g zinc acetate, and add them to a four-necked flask with mechanical stirring, condensation device, and thermometer In a nitrogen atmosphere, heating to 190°C and reacting for 1.5 hours to split the PET long chain into short-chain diols with hydroxyl terminated. Among them, the PET repeat unit molecular weight is 192g / mol.

[0035](2) Step (1) After the reaction is completed, a light yellow translucent liquid is obtained, and the alcoholysis solution is suction filtered while it is hot, and the filtrate obtained is ultrasonically washed with deionized hot water at 80°C, and then quickly placed in a high-speed centrifuge at 4000 rpm Centrifuge for 6 minutes to obtain the water-insoluble alcoholysis product. Take the precipitate and repeat the washing and centrifugation operation 3 times. Place the alcoholysis product in a vacuum drying oven wi...

Embodiment 3

[0039](1) Alcoholysis of waste PET: cut the waste PET bottle into small pieces, after washing, take 50g PET fragments, 48.49g ethylene glycol, 0.48g zinc acetate, and add them to a four-necked flask with mechanical stirring, condensation device, and thermometer In a nitrogen atmosphere, heating to 190°C and reacting for 1.5 hours to split the PET long chain into short-chain diols with hydroxyl terminated. Among them, the molecular weight of the PET repeating unit is 192 g / mol.

[0040](2) Step (1) After the reaction is completed, a light yellow translucent liquid is obtained, and the alcoholysis solution is suction filtered while it is hot, and the filtrate obtained is ultrasonically washed with deionized hot water at 80°C, and then quickly placed in a high-speed centrifuge at 4000 rpm Centrifuge for 6 minutes to obtain the water-insoluble alcoholysis product. Take the precipitate and repeat the washing and centrifugation operation 3 times. Place the alcoholysis product in a vacuum dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com