A tape preheating device for an edge banding machine

A technology of preheating device and edge banding machine, which is applied to household components, wood processing appliances, etc., can solve the problems of inability to seal edges, waste of energy, overheating of edge banding tapes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

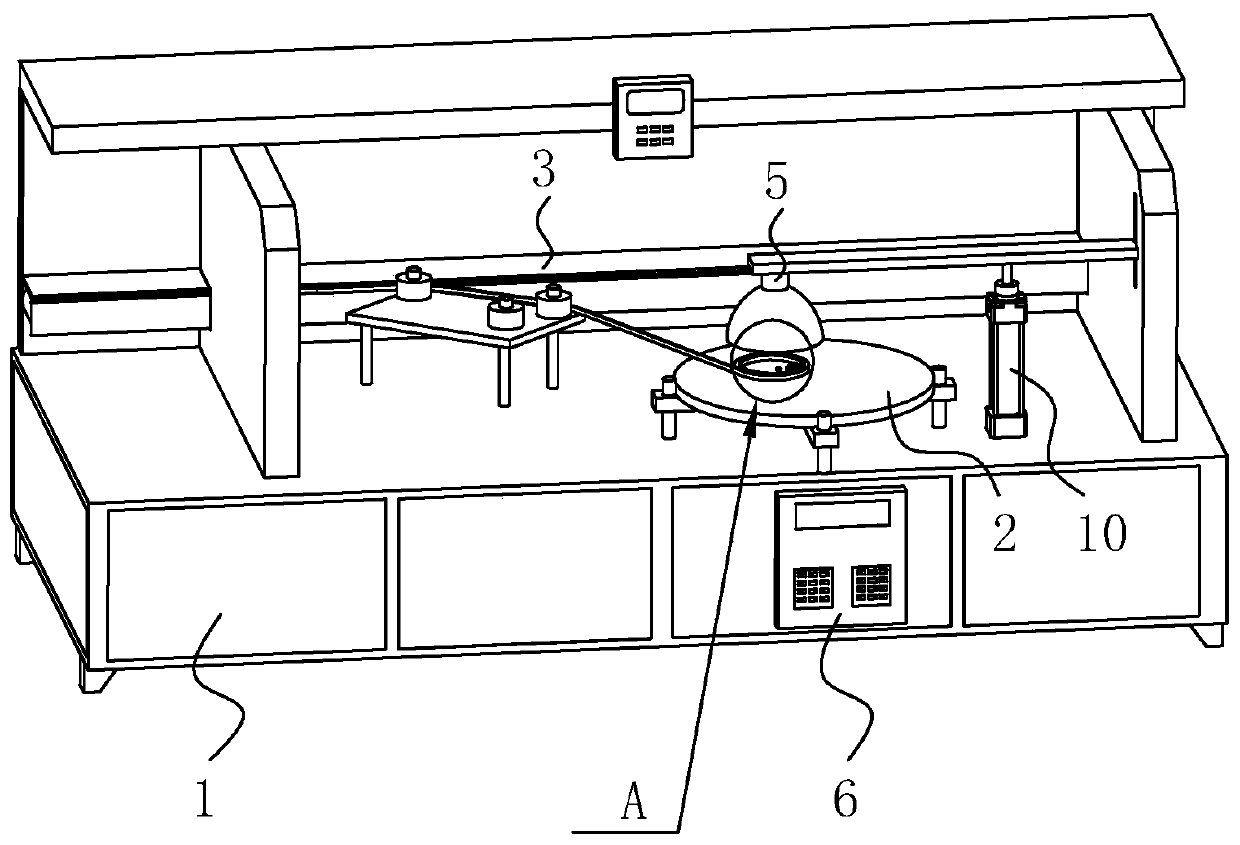

[0041] An edge banding machine tape preheating device, such as figure 1 As shown, it includes an edge banding main body 1 fixedly placed on the ground, and the edge banding main body 1 is used for fixedly combining the separation edge banding tape with the wood product. One end of the edge banding main body 1 is the entrance of the edge banding tape and the wooden product, and the other end is the exit of the finished product. The entrance is fixedly connected with a tape reel 2 for placing the edge banding tape. Conveyor belt for conveying wood products 3. The edge banding tape rolled into disc shape is placed on the tape reel 2, and one end of the edge banding tape stretches into the entrance and combines with the wooden product, and the edge banding tape rotates on the tape reel 2 under the drive of the wood product.

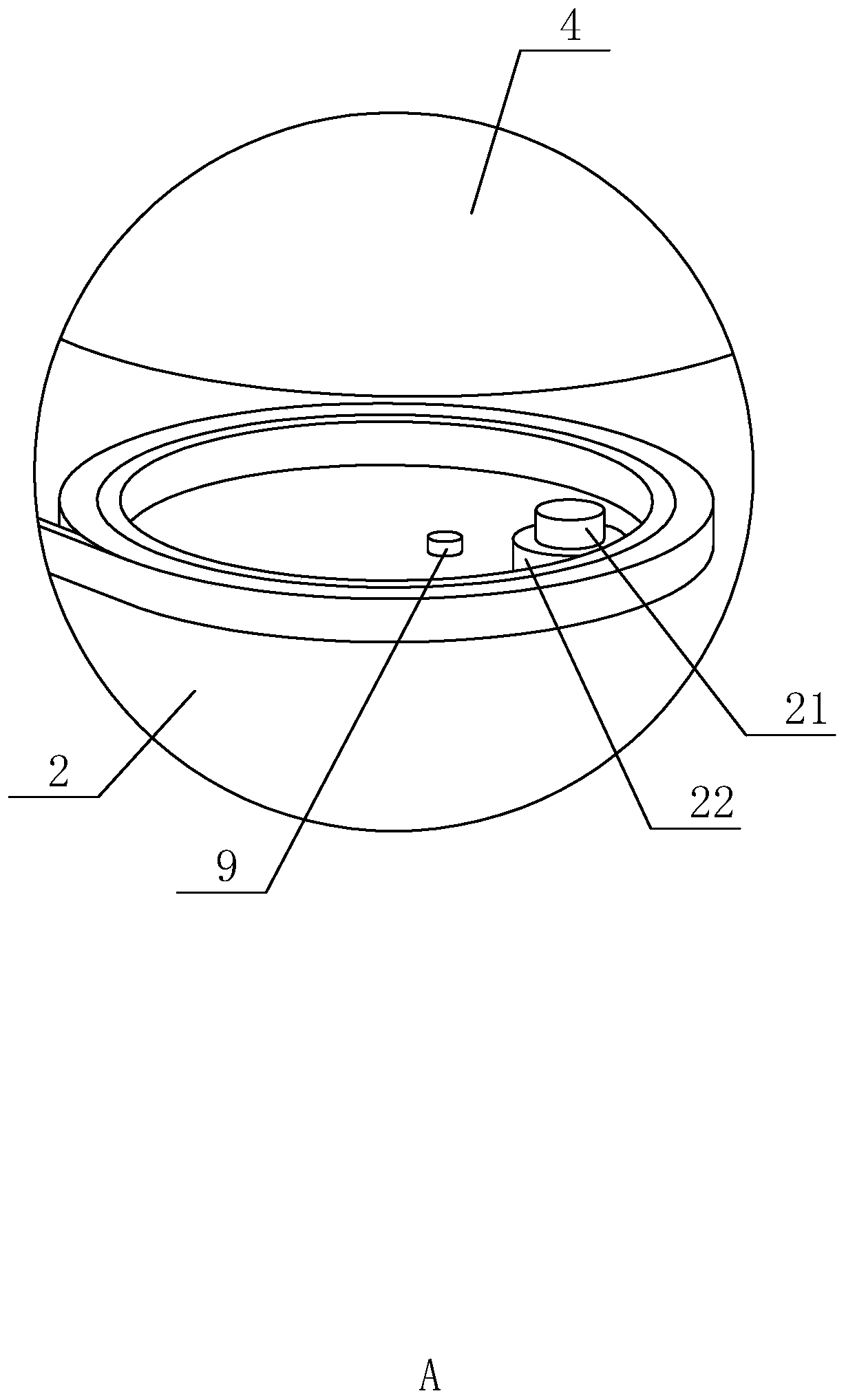

[0042] Such as figure 2 As shown, the middle part of the adhesive tape reel 2 is fixedly connected to the positioning rod 21 extending vertically upwards,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com