A special low-silicon and ultra-low-carbon covering agent for automobile sheet steel and its preparation method

A covering agent and automobile plate technology, applied in the metallurgical field, can solve the problems of inability to absorb impurities, large dust and smoke, and adverse effects on the environment and operators, and achieve the effects of easy carbon increase, good quality, and improved labor productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

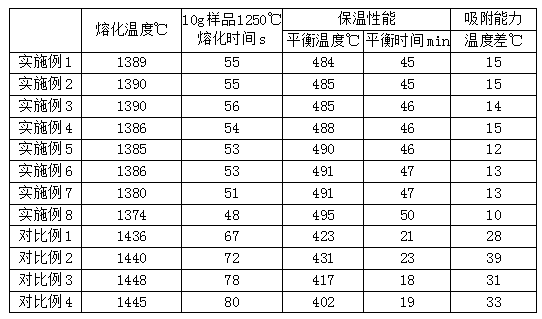

Examples

Embodiment 1-6

[0032] A special low-silicon ultra-low-carbon covering agent for automobile sheet steel, comprising the following components in mass percentage: SiO2 ≤3.0%, CaO 40.0~50.0%, C ≤1.0%, Al 2 o 3 20.0-30.0%, MgO 6.0~14.0%, Fe 2 o 3 ≤3.0%, S≤0.04%, and the rest are unavoidable impurities. The composition of embodiment 1-6 covering agent is shown in table 1.

[0033] The covering agent is prepared from sintered material, calcium carbonate powder, magnesia, and binder according to the ingredients in Examples 1-6, wherein the binder is carboxymethyl cellulose.

[0034] The sintered material comprises the following components in mass percentage: SiO 2 ≤2.5%, CaO 45.0~55.0%, Al 2 o 3 30.0~40.0%, S≤0.05%, C≤0.3, and the rest are unavoidable impurities. The composition of the sintered material of Examples 1-6 is shown in Table 2.

[0035] Table 1 The mass percent of each component of embodiment 1-6 covering agent

[0036] SiO2, % CaO, % C,% Al2O3,% MgO,% Fe2O3,...

Embodiment 7

[0052] A special low-silicon and ultra-low-carbon covering agent for automobile sheet steel, the components and raw materials contained in the mass fraction are the same as those in Example 5.

[0053] The preparation method of a special low-silicon ultra-low-carbon covering agent for automobile sheet steel described in this embodiment comprises the following steps:

[0054] S1: Weigh the sintered material, calcium carbonate powder and magnesia and put them in a mixer for mixing. Binder, adjusting rotating speed is 700r / min, and the time is 8min, obtains mixed material 1;

[0055] S2: Elevate the mixed material 1 obtained in step S1 to the silo, add water to stir and humidify, the weight of the water is 12% of the weight of the mixed material 1, adjust the rotating speed to 700r / min, and the time is 8min, to obtain the mixed material 2;

[0056] S3: Put the mixed material 2 obtained in step S2 on an extruder to extrude and granulate at an extrusion temperature of 85°C and an ...

Embodiment 8

[0060] A special low-silicon and ultra-low-carbon covering agent for automobile sheet steel. The components and raw materials contained in the mass fraction are the same as those in Example 7, but the difference from Example 7 is that 0.5% silane coupling agent is added in this example.

[0061] The preparation method of the special low-silicon and ultra-low-carbon covering agent for automobile sheet steel is the same as in Example 7, wherein, in step S1, the adhesive and the silane coupling agent are added at the same time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com