Continuously-feeding grinding device for medicinal material processing

A technology of processing and grinding equipment for medicinal materials, which is applied in applications, separating solids from solids with airflow, solid separation, etc. It can solve the problems of limited production efficiency, small amount of grinding at one time, and slow processing of medicinal materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

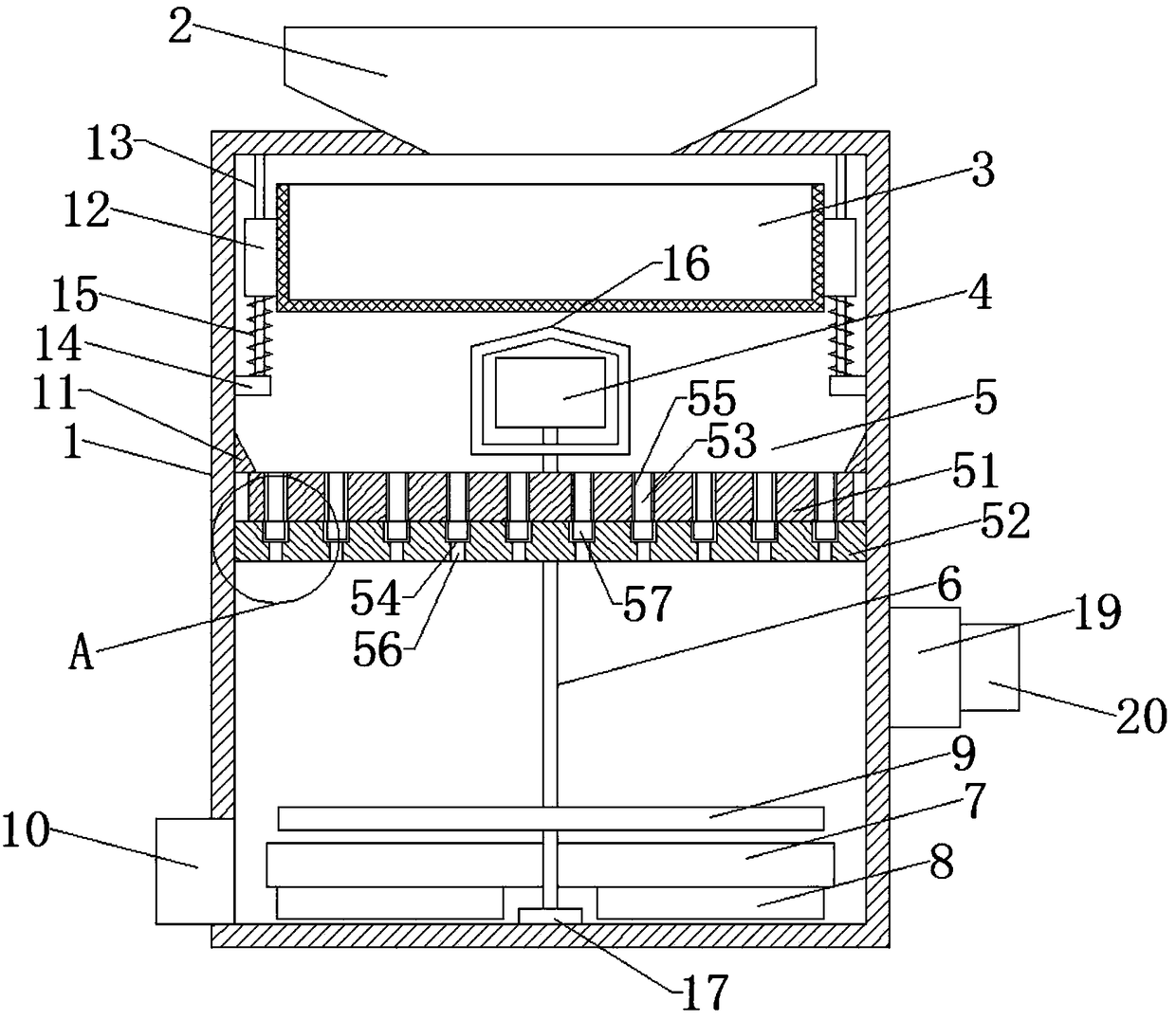

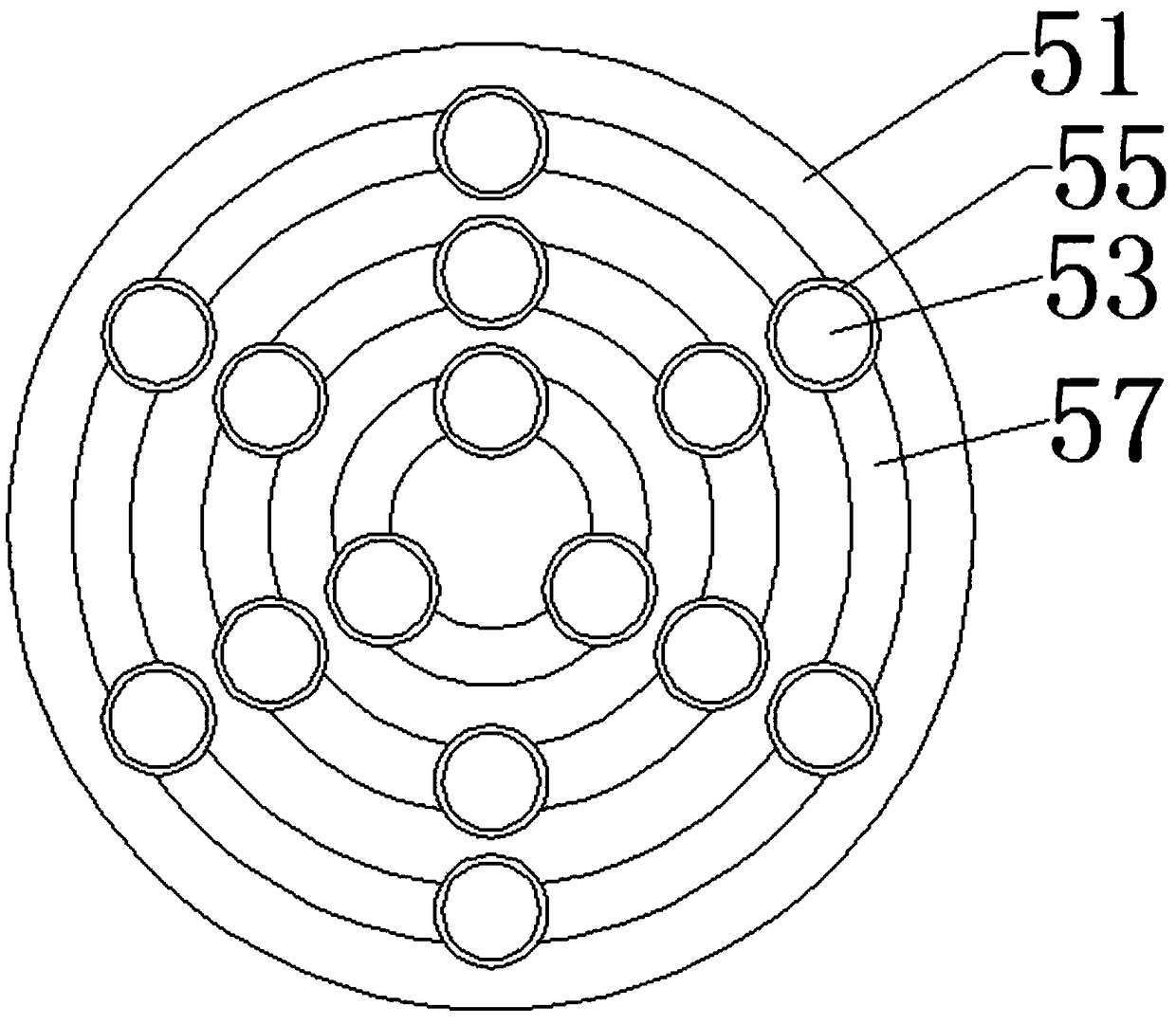

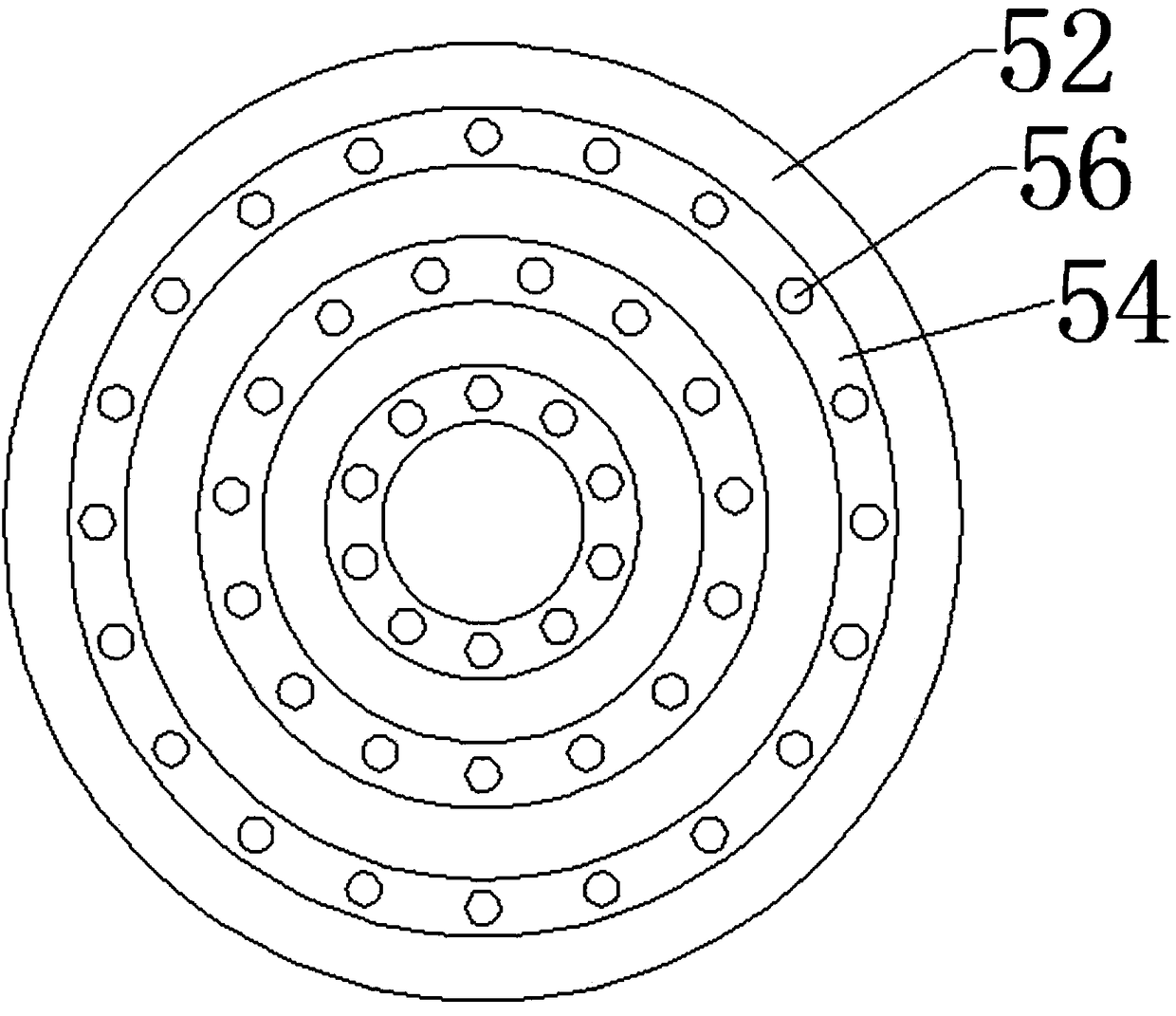

[0020] Please refer to the figure, in the embodiment of the present invention, a grinding device for continuous feeding medicinal material processing includes a housing 1, a feeding hopper 2, a sieve box 3 and a motor 4; the feeding hopper 2 communicates with the housing 1 The top of the screen box 3 is set on the upper part of the housing 1, the screen box 3 is processed and welded by stainless steel mesh to form a box structure, the two ends of the screen box 3 are fixed and welded with sliding sleeves 12 with vertical through holes, the sliding A vertical slide bar 13 is pierced in the sleeve 12, the upper end of the slide bar 13 is fixed on the top in the housing 1, and the lower end is fixedly connected with a support seat 14, and the support seat 14 is fixed on the inner wall of the housing 1 to support the slide bar. 13. A spring 15 is set on the sliding rod 13 below the sliding sleeve 12, and the sliding sleeve 12 is supported by the spring 15, so that the medicinal mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com