Kiwifruit cleaning dehairing device

A kiwifruit and equipment technology, applied in the field of kiwifruit cleaning and dehairing equipment, can solve the problems of unfavorable direct consumption of kiwifruit, high labor cost, large labor and material resources, etc., and achieves better process efficiency, increase process efficiency, and ensure the effect of continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Further detailed explanation through specific implementation mode below:

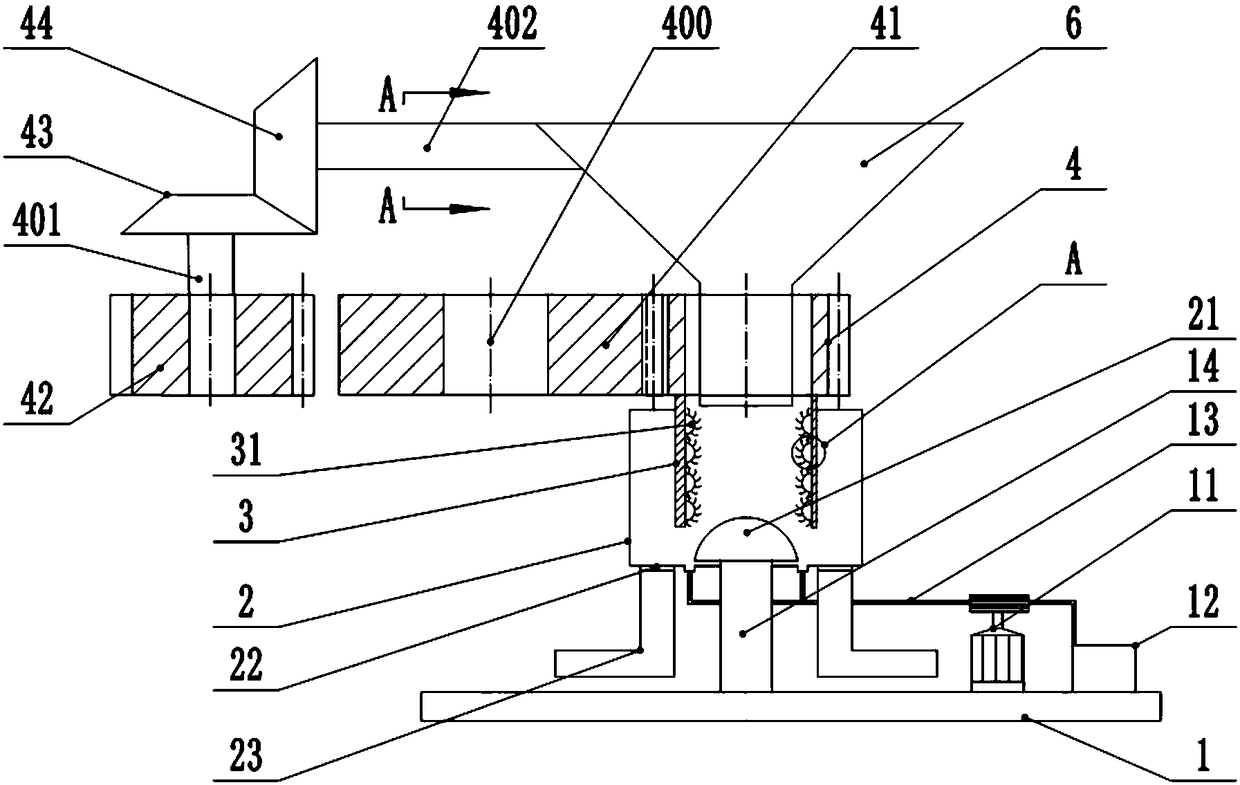

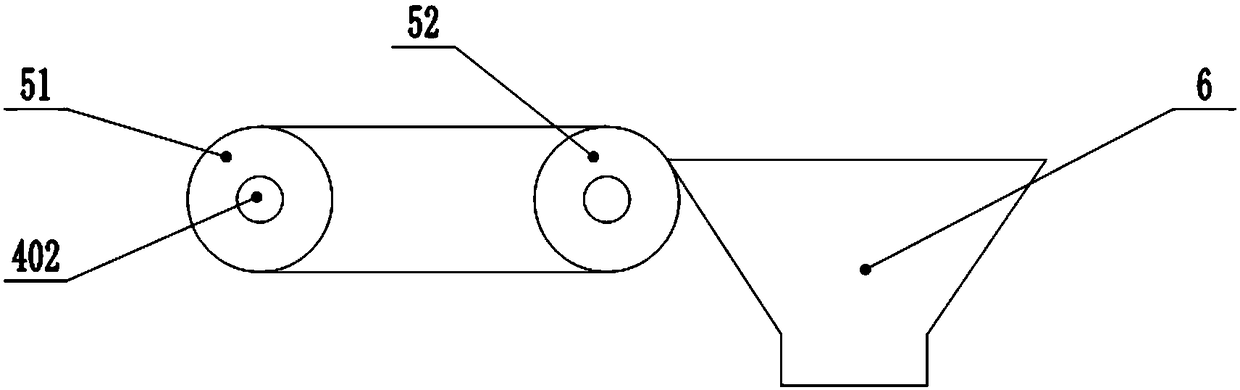

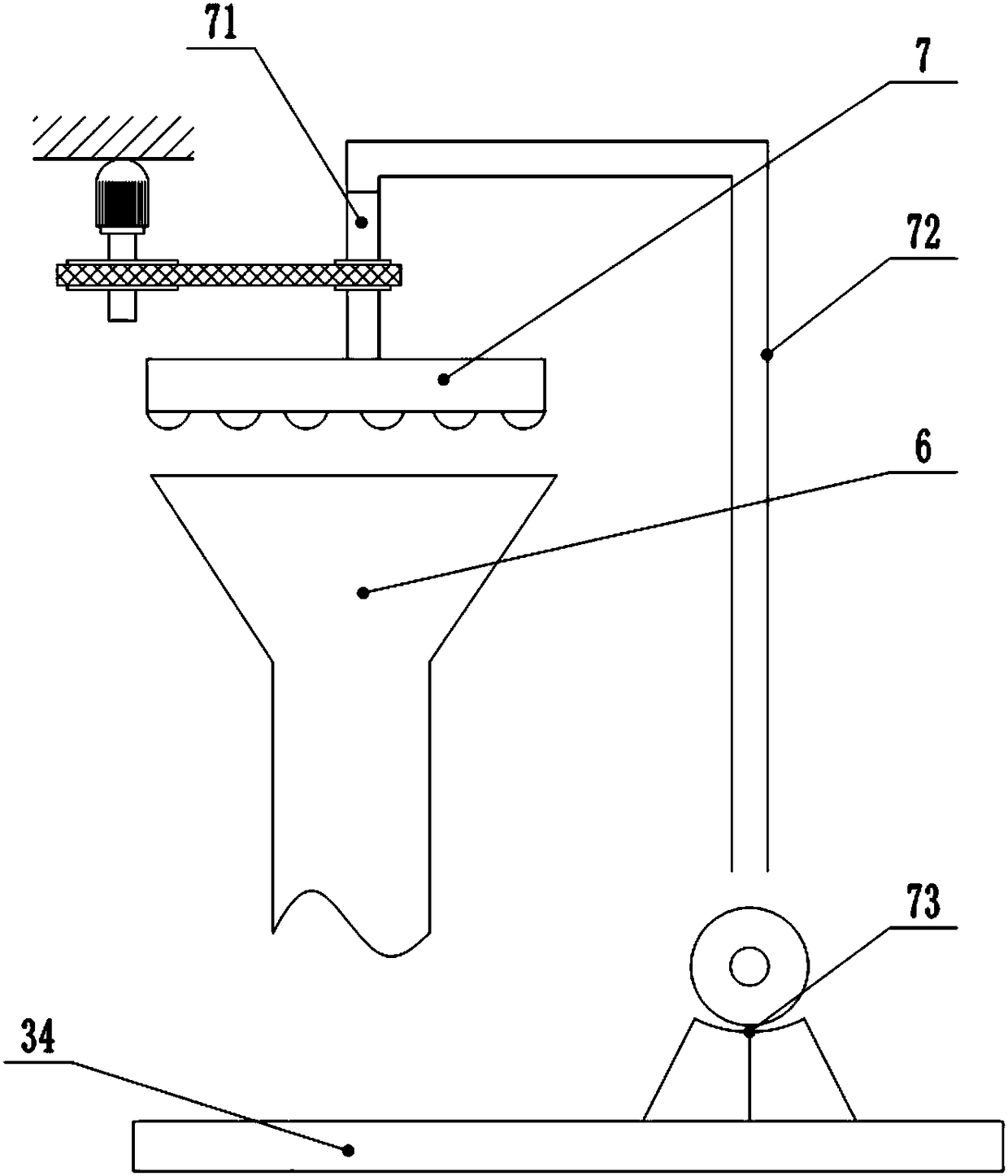

[0026] The reference signs in the drawings of the description include: base 1, suction pump 11, water collection tank 12, sewage pipe 13, pillar 14, box body 2, first air bag 21, discharge port 22, discharge pipe 23, baffle plate 3, the second airbag 31, hollow rod 311, piston 312, spring 313, hair brush 314, first gear 4, half gear 41, rotating shaft 400, second gear 42, gear shaft 401, first bevel gear 43, second Bevel gear 44, tension shaft 402, driving roller 51, driven roller 52, hopper 6, nozzle 7, shaft rod 71, water inlet pipe 72, water pump 73.

[0027] The embodiment is basically as attached figure 1 Shown:

[0028] Kiwi cleaning and hair removal equipment, including a frame, a base 1, a box body 2, a first gear 4 and a hopper 6, the base 1 is provided with a pillar 14 that runs through the bottom of the box body 2, the top of the pillar 14 is provided with a first air bag 21, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com