Preparation method of Gongfu black tea

A technology for kung fu black tea and fresh tea leaves, which is applied in the direction of pre-extraction tea treatment, etc., to achieve the effect of improving the sliver rate, sweet and mellow taste, and improving toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

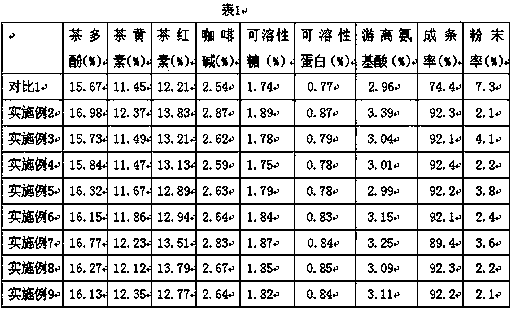

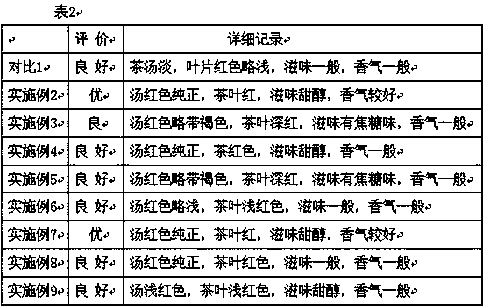

Examples

Embodiment 1

[0024] A preparation method of kung fu black tea is characterized in that fresh picked tea leaves are soaked in an aqueous solution for a period of time, taken out and drained, and subjected to withering, rolling, fermentation and drying to obtain kung fu black tea.

Embodiment 2

[0026] A kind of preparation method of kung fu black tea, soak the fresh tea leaves after plucking in the aqueous solution for 20min, the mass ratio of the fresh tea leaves and the aqueous solution is 1:2, remove and drain, after withering, rolling, fermenting and drying, Get kung fu black tea.

[0027] The aqueous solution is a composition of fructose and ethanol at a mass ratio of 1:5; the concentration of the aqueous solution is 6%.

[0028] The withering temperature is 28° C., and the weight loss rate of fresh leaves reaches 35%.

[0029] The kneading adopts a kneading machine to knead, the kneading speed is 20r / min, and the kneading time is 15min.

[0030] The fermentation conditions are 65% humidity, 30°C temperature and 6 hours.

[0031] The drying is divided into rough fire drying and full fire drying; the inlet temperature of the rough fire drying dryer is 115°C, the thickness of the leaves is 1.5cm, and the leaves are dried until the water content of the leaves is ...

Embodiment 3

[0035] A kind of preparation method of kung fu black tea, soak the fresh tea leaves after plucking in the aqueous solution for 20min, the mass ratio of the fresh tea leaves and the aqueous solution is 1:2, remove and drain, after withering, rolling, fermenting and drying, Get kung fu black tea.

[0036] The aqueous solution is a composition of fructose and ethanol at a mass ratio of 1:5; the concentration of the aqueous solution is 6%.

[0037] The withering temperature is 28° C., and the weight loss rate of fresh leaves reaches 35%.

[0038] The kneading adopts a kneading machine to knead, the kneading speed is 20r / min, and the kneading time is 15min.

[0039] The fermentation conditions are 65% humidity, 30°C temperature and 6 hours.

[0040] The drying is divided into rough fire drying and full fire drying; the inlet temperature of the rough fire drying dryer is 125°C, the thickness of the leaves is 1.5cm, and the leaves are dried until the water content of the leaves is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com