Regulating device for exhaust gas turbocharger and exhaust gas turbocharger

A technology for exhaust gas turbines and superchargers, which is applied in mechanical equipment, gas turbine devices, shafts and bearings, etc., and can solve problems such as loosening, stress material fatigue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

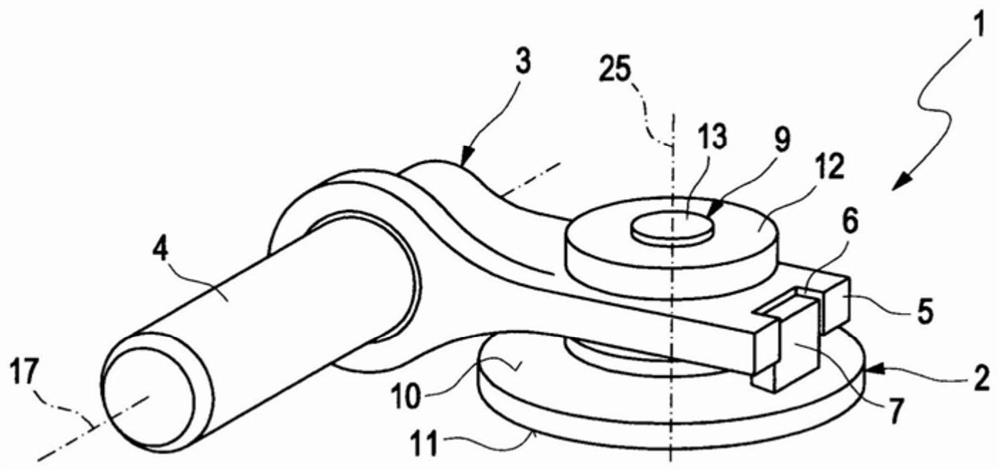

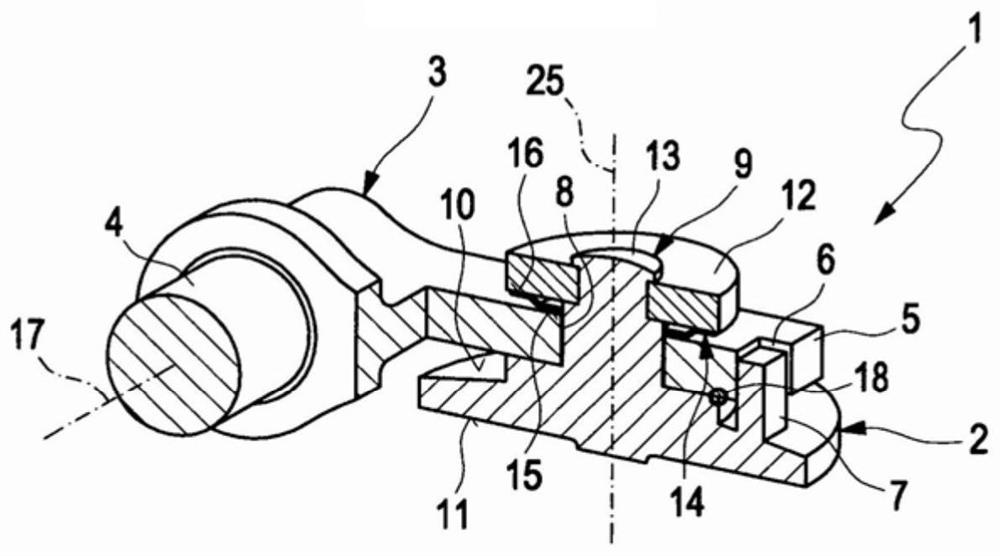

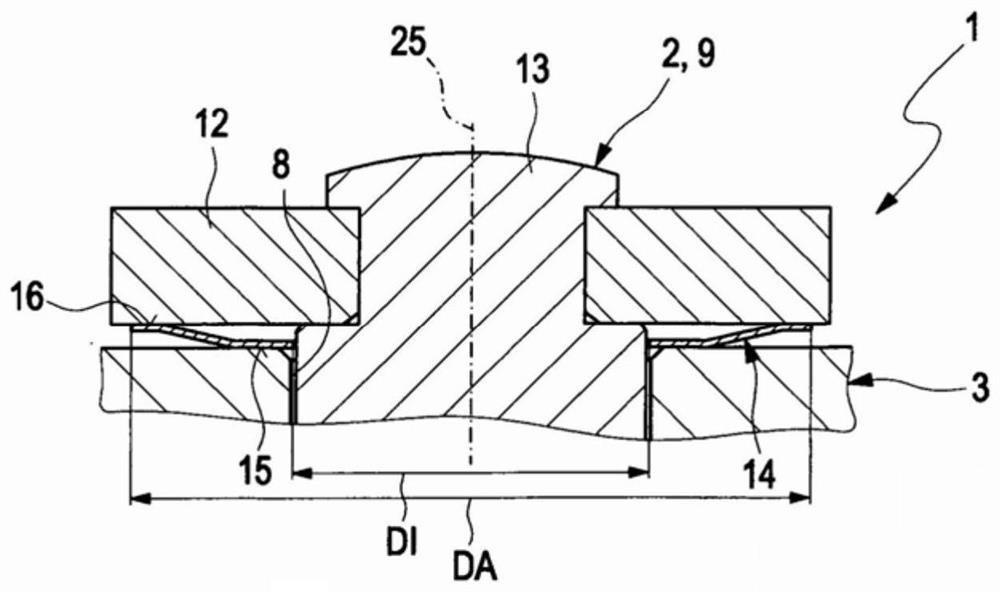

[0024] The control device 1 of an exhaust gas turbocharger according to the prior art, not shown in detail, is constructed as shown in FIG. 1 . The exhaust gas turbocharger has a flow-through exhaust gas guide section, not shown in detail, through which a fluid, usually exhaust gas, flows during operation of the exhaust gas turbocharger. Exhaust gases are generally combustion products of internal combustion engines not shown in detail. Such a control device is known under the term wastegate device.

[0025] The exhaust gas turbocharger is assigned a flow-through air guide section, not shown in detail, and a bearing section, not shown in detail, positioned between the exhaust gas guide section and the air guide section, wherein the bearing section is A rotor arrangement not shown in detail is accommodated rotatably in the . The rotor arrangement has a compressor wheel (not shown in detail) and a turbine wheel (not shown in detail), which are connected to one another in a rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com