Turbojet engine with thrust take-up means on the inter-compressor case

A compressor housing and turbojet technology, applied in the field of aviation propulsion, can solve the problems of low mechanical strength, increased weight and low mechanical strength of the compressor housing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

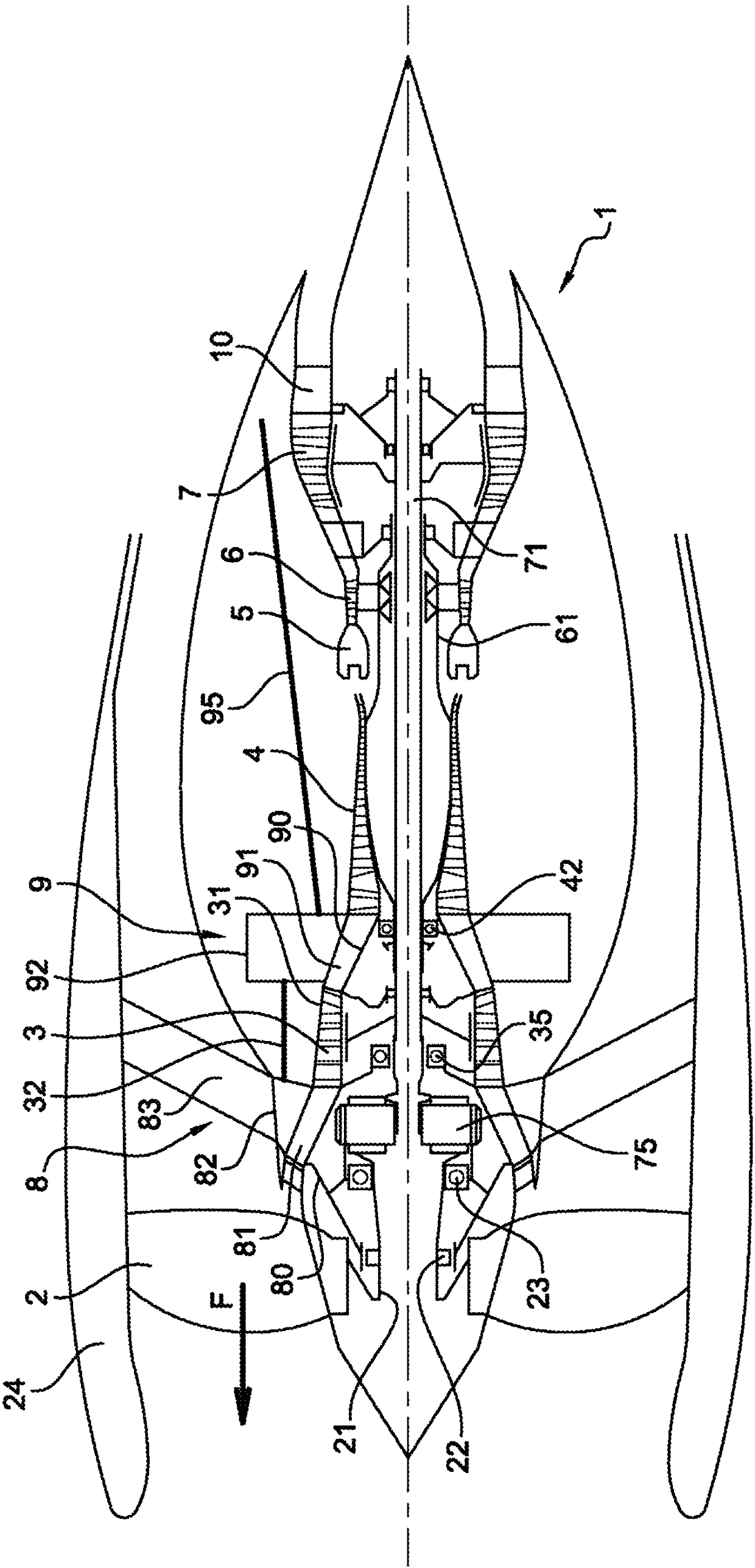

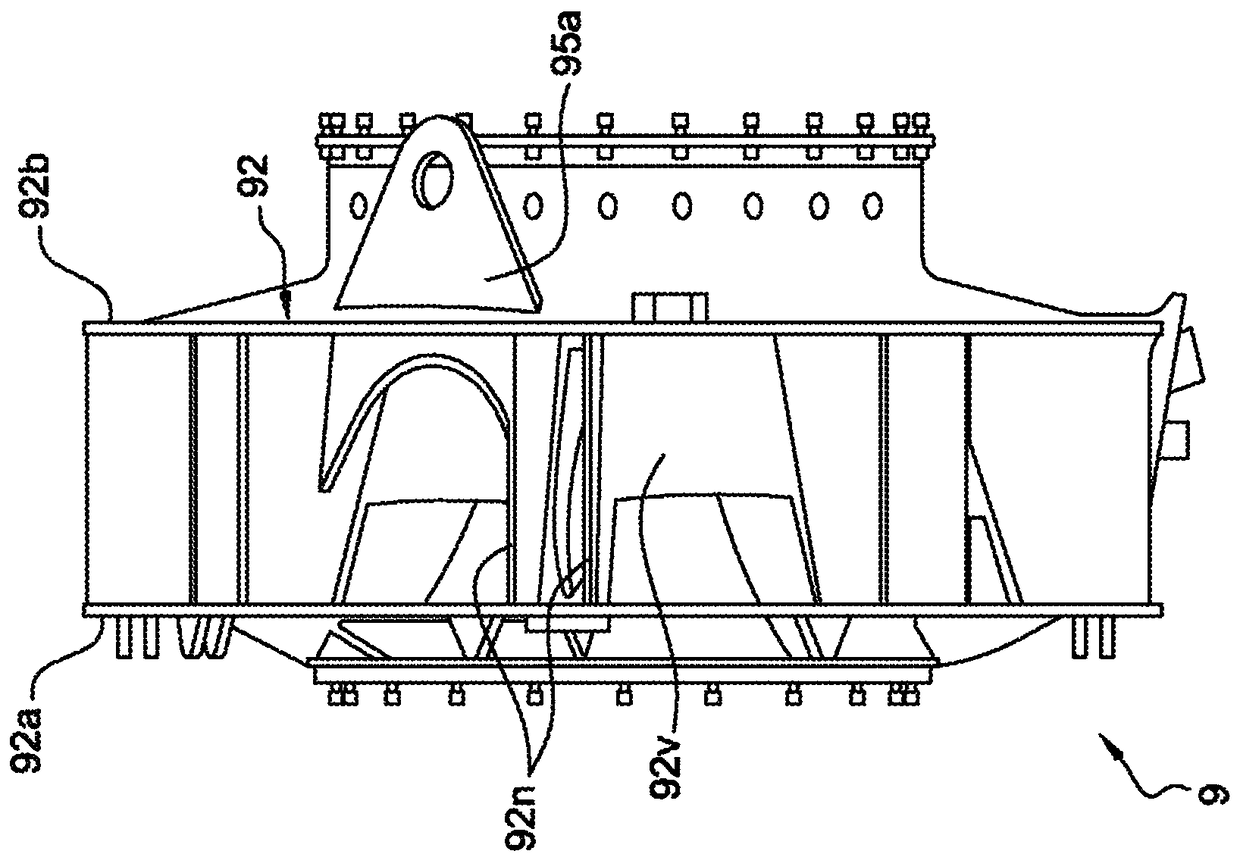

[0046] figure 1 Shown is a turbojet engine 1 with a ducted fan 2 from upstream to downstream and a gas twin formed by a first compressor 3 , a second compressor 4 , a combustion chamber 5 and two successive turbines 6 and 7 generator. The first compressor forms a low-pressure BP body together with the turbine 7 and is connected to the turbine 7 through a turbine shaft 71 . The second compressor 4 together with the turbine 6 forms a high-pressure HP body, and the second compressor is connected with the turbine 6 through a turbine shaft 61 . The fixed structural members that transfer the stress from the engine to the suspension include: the inlet housing 8 (at the inlet of the gas generator between the ducted fan 2 and the BP compressor 3 ), between the BP compressor 3 and the HP An intermediate compressor casing 9 between the compressors 4, and a discharge casing 10 downstream.

[0047] The shaft 21 of the ducted fan is rotatably mounted in two bearings 22 and 23, of which t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com