wound dressing sheet

A covering material and wound technology, applied in the field of wound covering sheets of natural or regenerated cellulose fibers, can solve the problems of inability to be used for wound healing, increased strength, poor liquid absorption, etc., and achieve the effect of promoting wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

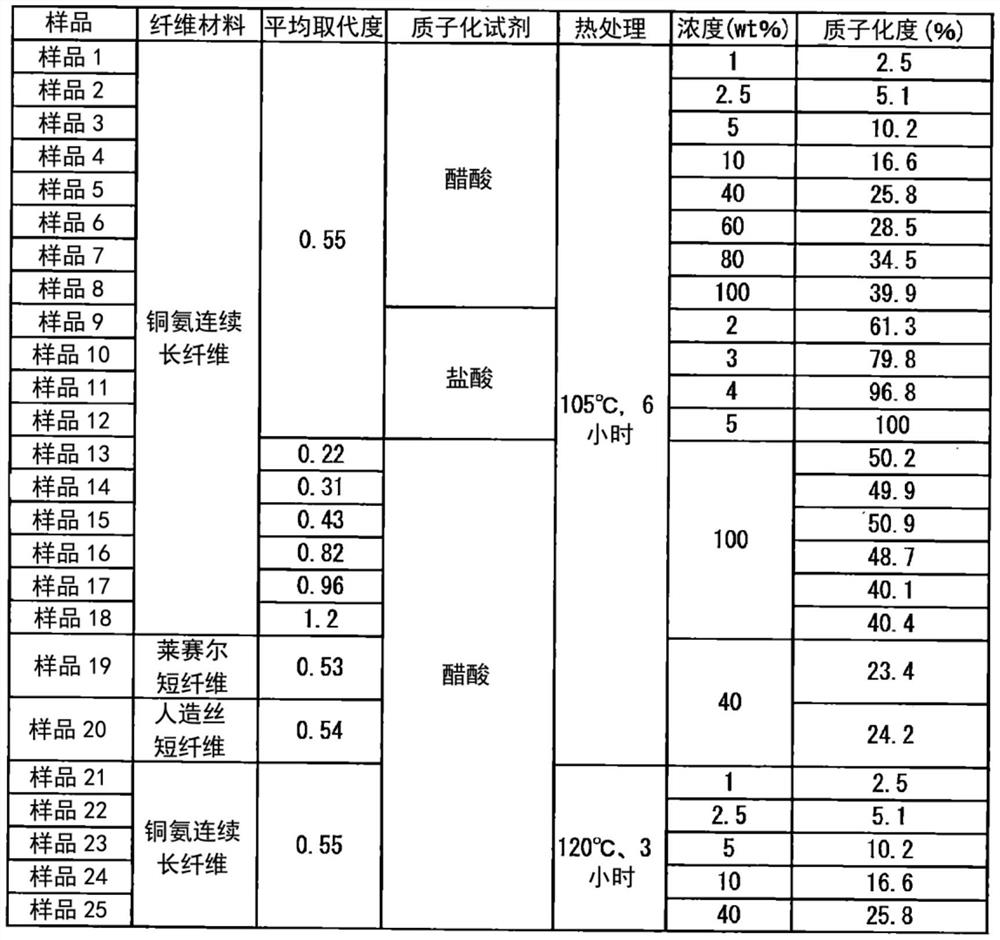

[0072] Hereinafter, the present invention will be specifically described using examples, but the present invention is not limited to these examples.

reference example 1

[0074] Regenerated cellulose continuous long fiber sheet structure (cupro fiber sheet structure) (width 20cm, weight per unit area 80g / m 2 , thickness 0.5mm, density 0.154g / m 3 ), lyocell staple fiber nonwoven fabric, or rayon staple fiber nonwoven fabric 100g was put into the reaction container, and then, after adding sodium hydroxide-containing ethanol aqueous solution (water: 875g, ethanol 875g, NaOH: 162.5g) , stirred at 35 °C for 30 min. Next, after the reagent in the reaction vessel was discharged, an aqueous ethanol solution (300 g of water, 960 g of ethanol, and 122.5 g of sodium monochloroacetate) containing sodium monochloroacetate was added, and stirred at 30° C. or 50° C. for 1 to 12 hours. Then, it was dried to obtain a carboxymethylated sheet-like structure. The sheet-like structure obtained above was adjusted to pH 6.0 to 8.0 with an aqueous ethanol solution containing acetic acid (acetic acid: 37.5 g, distilled water: 375 g, ethanol: 875 g), washed once with ...

reference example 2

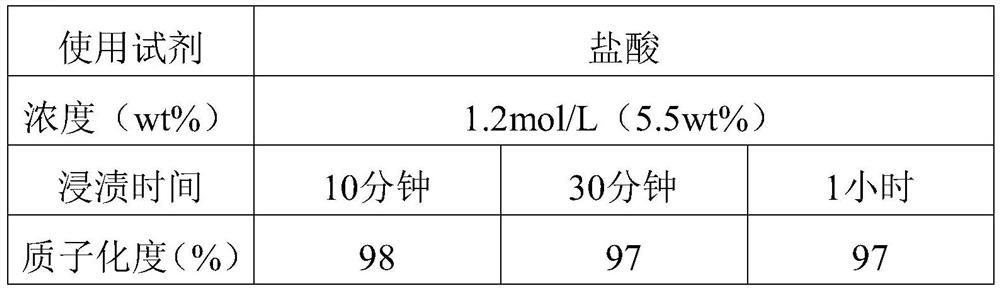

[0079] Slices (2 cm×1 cm) were cut out from the pre-protonated CMC sheet-like structure (substitution degree 0.55) obtained by the method of Reference Example 1, and 10 slices were placed in 50 mL plastic tubes. 30 mL of an aqueous methanol solution containing hydrochloric acid (1.2 mol / L hydrochloric acid, 90% methanol) was added to each tube, and incubated at room temperature for 10 minutes, 30 minutes, and 1 hour.

[0080] After incubation, it was washed sequentially with 80% aqueous methanol and 100% methanol, and dried to obtain a protonated sheet-like structure. The data of the degree of protonation are shown in Table 2 below together with the protonation conditions.

[0081] [Table 2]

[0082]

[0083] It was found that almost 100% of the substituents were protonated at the concentration of hydrochloric acid in Reference Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com