Boiler primary air heating device provided with flue gas tubular heat exchanger

A tubular heat exchanger and heating device technology, applied in lighting and heating equipment, combustion air/fuel supply, combustion methods, etc., can solve the problem of low primary air temperature, insufficient system output, poor drying capacity of the pulverizing system, etc. problems, to achieve the effect of guaranteed output, simple system, and elimination of high temperature safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

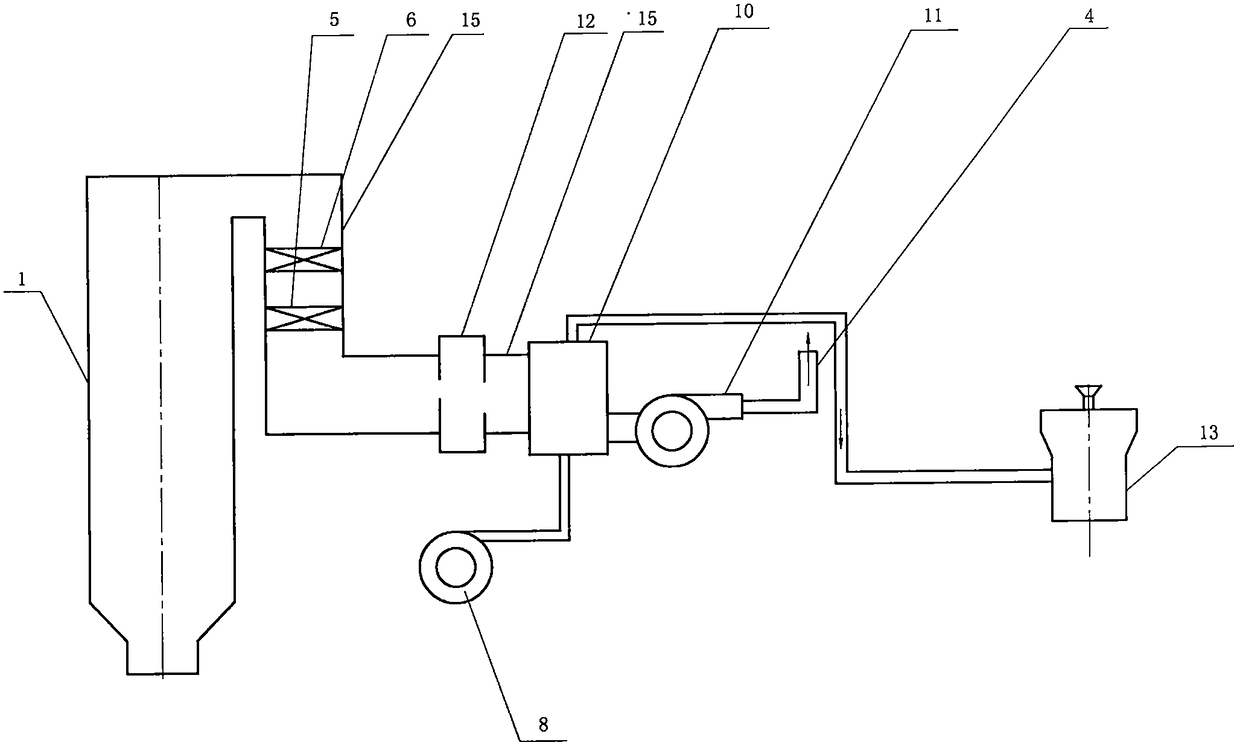

[0025] Such as figure 2 As shown, the existing boiler includes: a furnace 1, a flue 15, a primary fan 8, a boiler economizer 5, a horizontal low-temperature superheater 6, a chimney 4, an induced draft fan 11, an out-of-stock device 12, an air preheater 10 and a mill Coal machine 13, the upper end of the furnace 1 communicates with the flue 15, the horizontal low-temperature superheater 6 and the boiler economizer 5 are successively installed at the upper and lower positions of the flue 15, and the outlet end of the flue 15 is sequentially connected with the removal device 12 and the air The preheaters 10 are connected in series, the hot air inlet of the air preheater 10 is connected with the flue 15, the hot air outlet is connected with the chimney 4 through the induced draft fan 11, and the primary fan 8 is connected with the air inlet of the air preheater 10, The air outlet of the air preheater 10 is connected with the air inlet of the coal mill 13 .

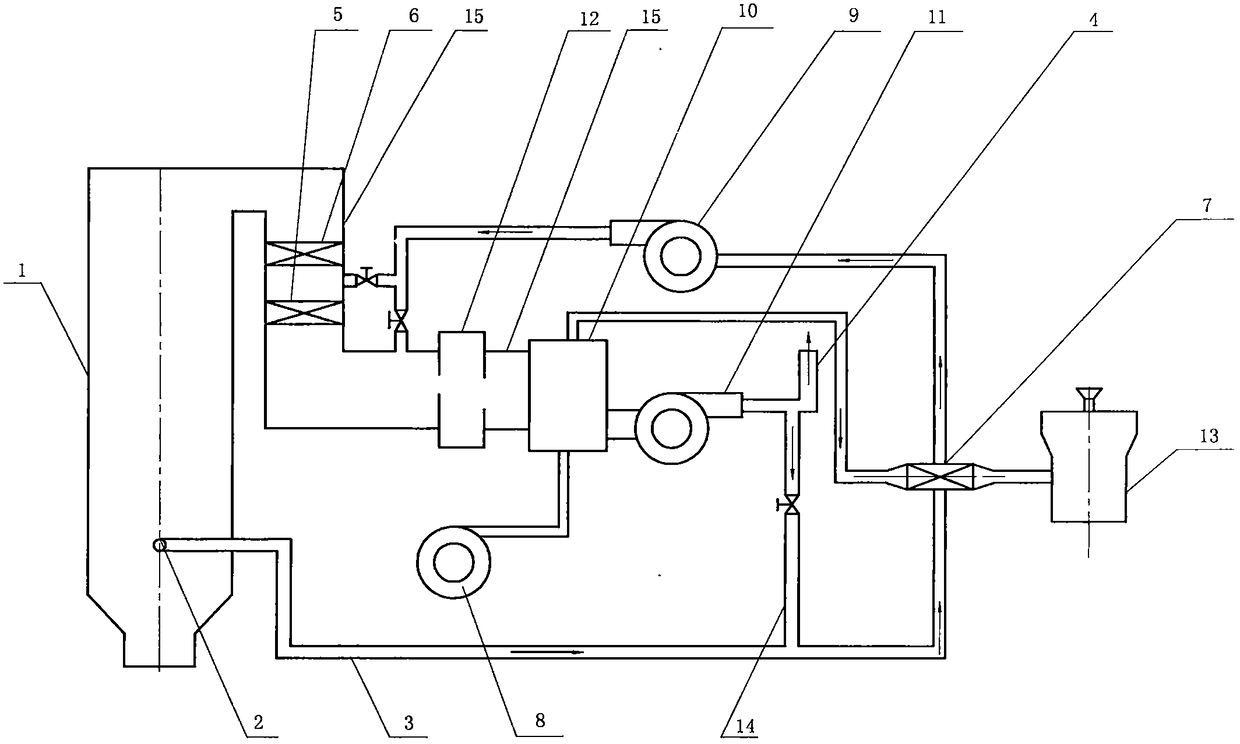

[0026] Such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com