Autotrophic denitrification advanced denitrification device and autotrophic advanced denitrification method

A technology of autotrophic denitrification and deep denitrification, applied in the field of autotrophic denitrification deep denitrification devices, can solve the problems of backwashing, bed thickness, sulfur loss, etc., and achieve the effect of ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

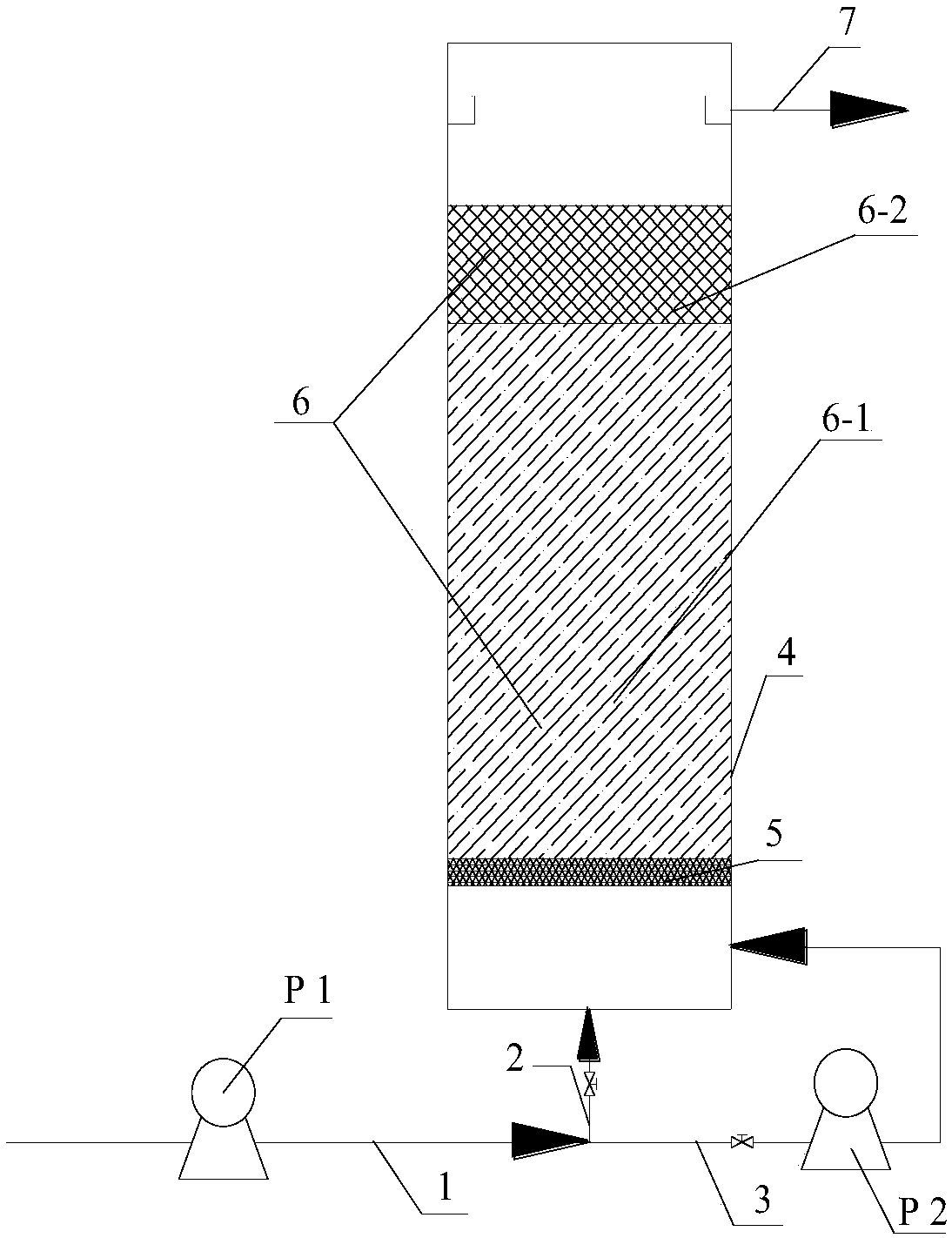

[0064] The autotrophic deep denitrification method provided in this example is as figure 1 The autotrophic denitrification deep denitrification device shown is carried out. In a volume of 11.58m 3 The autotrophic bioreactor is filled from bottom to top with sulfur particles with a height of 1.2m and a particle size of 3-5mm and a height of 0.12m with a particle size of 5-20mm. The filling of sulfur fillers and suspended fillers The height ratio is 10:1. The autotrophic bioreactor was inoculated with sludge containing autotrophic denitrifying bacteria as seed sludge. Pass the nitrate-containing wastewater from the bottom of the autotrophic bioreactor into the domesticated reactor through the water injection pump and the water inlet pipe, and increase the nitrate nitrogen load in the influent water from 0 to 0.2kg-N / m at a uniform speed within 7 days 3 / d, to achieve film formation on the filler. After the completion of the film formation on the filler, the thickness of the b...

Embodiment 2

[0066] The autotrophic deep denitrification method provided in this example is as figure 1 The autotrophic denitrification deep denitrification device shown is carried out. In a volume of 11.58m 3 Fill the autotrophic bioreactor with sulfur particles with a particle size of 3-5mm at a height of 1.5m and suspended filler particles with a particle size of 5-20mm at a height of 0.15m from bottom to top, and the filling of sulfur fillers and suspended fillers The height ratio is 10:1. The autotrophic bioreactor was inoculated with sludge containing autotrophic denitrifying bacteria as seed sludge. Pass the nitrate-containing wastewater from the bottom of the autotrophic bioreactor into the domesticated reactor through the water injection pump and the water inlet pipe, and increase the nitrate nitrogen load in the influent water from 0 to 0.2kg-N / m at a uniform speed within 7 days 3 / d, to achieve film formation on the filler. After the completion of the film formation on the fi...

Embodiment 3

[0068] The autotrophic deep denitrification method provided in this example is as figure 1 The autotrophic denitrification deep denitrification device shown is carried out. In a volume of 11.58m 3 Fill the autotrophic bioreactor with sulfur particles with a particle size of 3-5mm at a height of 1.8m and suspended filler particles with a particle size of 5-20mm at a height of 0.225m from bottom to top, and the filling of sulfur fillers and suspended fillers The height ratio is 8:1. The autotrophic bioreactor was inoculated with sludge containing autotrophic denitrifying bacteria as seed sludge. Pass the nitrate-containing wastewater from the bottom of the autotrophic bioreactor into the domesticated reactor through the water injection pump and the water inlet pipe, and increase the nitrate nitrogen load in the influent water from 0 to 0.2kg-N / m at a uniform speed within 7 days 3 / d, to achieve film formation on the filler. After the completion of the film formation on the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com