A Fluidized Bed for Batch Preparation of Carbon Nanotubes Based on Chemical Vapor Deposition

A chemical vapor deposition and carbon nanotube technology, which is applied in the field of fluidized bed, can solve the problems that the catalyst cannot be uniformly fluidized and affect the yield of activated carbon nanotubes of the catalyst, and achieves stable thermal field flow field and high quality repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

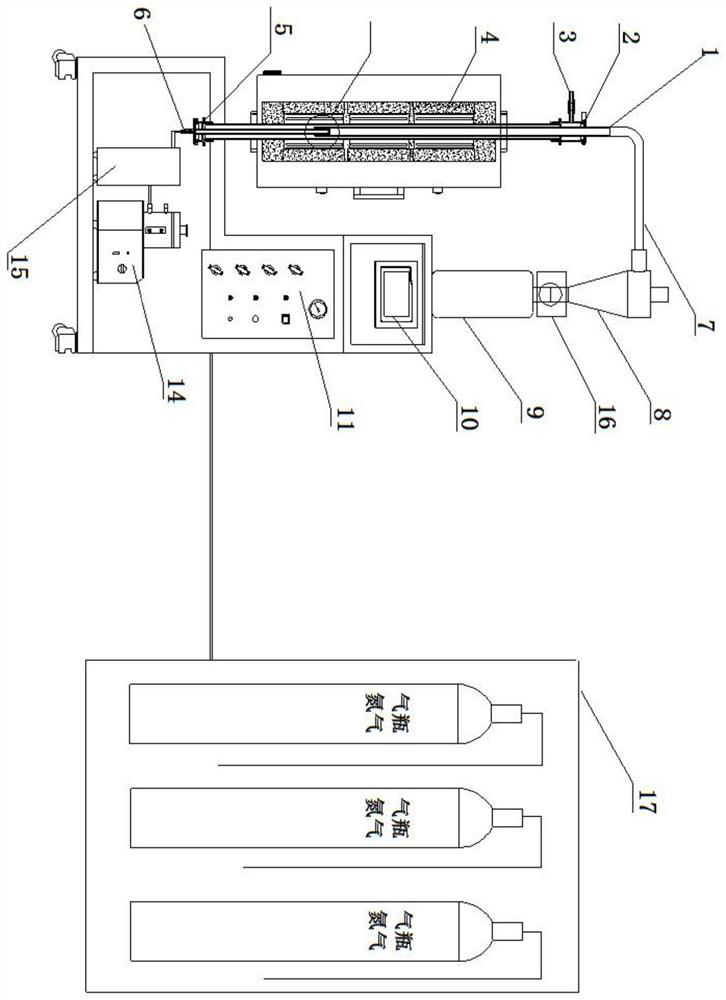

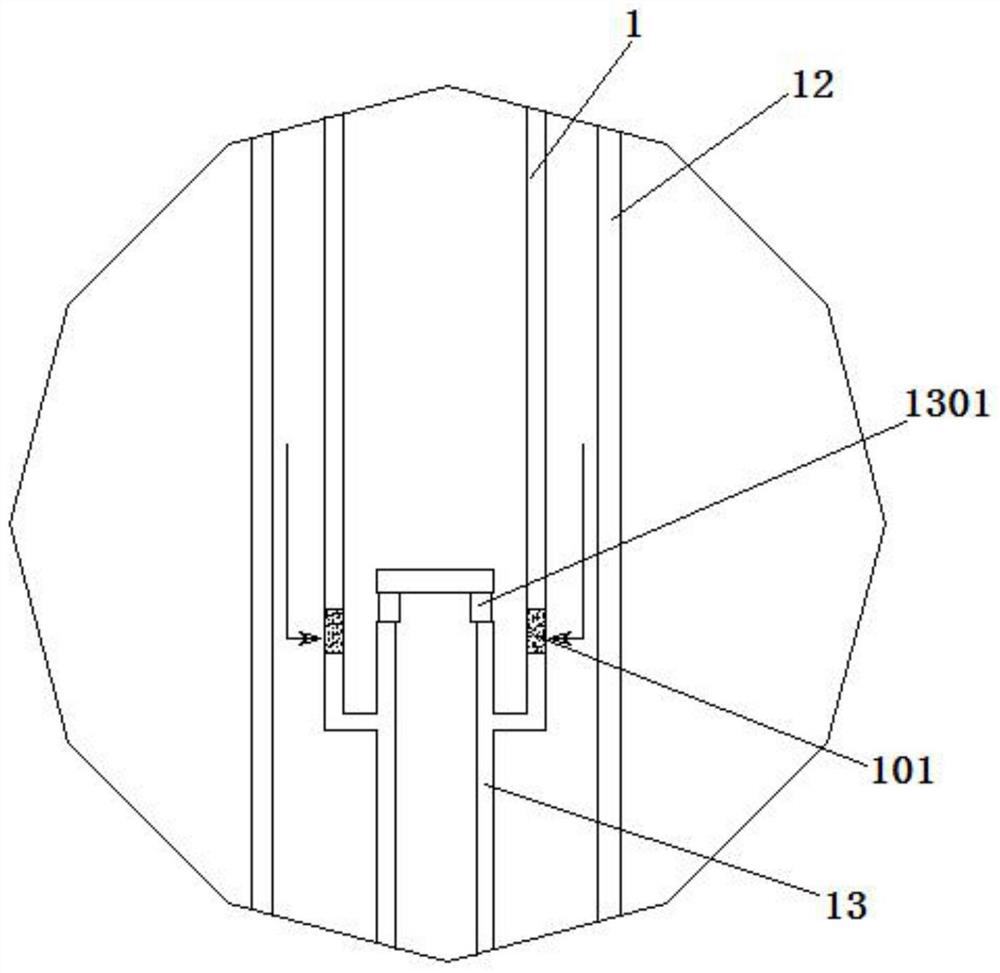

[0019] Such as Figure 1-2 As shown, a fluidized bed for preparing carbon nanotubes in batches based on the chemical vapor deposition method includes: an automatic liquid adding device 15, an ultrasonic atomization generating device 14, a gas supply device 17, a gas flow control device 11, and three temperature zones Fluidized bed reactor and heating device 4 , cyclone separator 8 , solid collection device 9 , purification treatment device 16 .

[0020] Wherein, the gas outlet of the gas supply device 17 is connected to the gas flow control device 11 through a trachea, and the other end of the gas flow control device 11 is also connected to the air inlet of the ultrasonic atomization generating device 14; the gas flow control The upper end of the device 11 is also provided with a touch screen operation interface 10, which is used to operate and control the device; the liquid outlet of the automatic liquid adding device 15 is connected to the liquid inlet of the ultrasonic atom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com