polisher

A polishing machine and workpiece technology, applied in the field of polishing machines, can solve the problems of difficult to guarantee polishing effect and quality, hidden dangers of health and safety, low polishing efficiency, etc., to improve polishing efficiency and safety, low manufacturing cost, and helpful effect on equipment cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

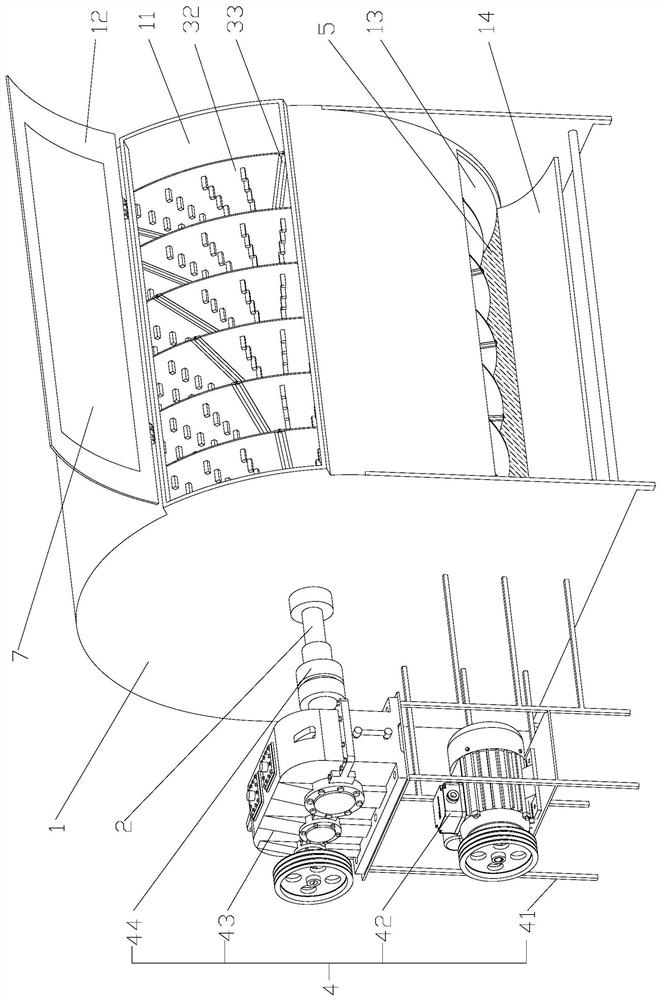

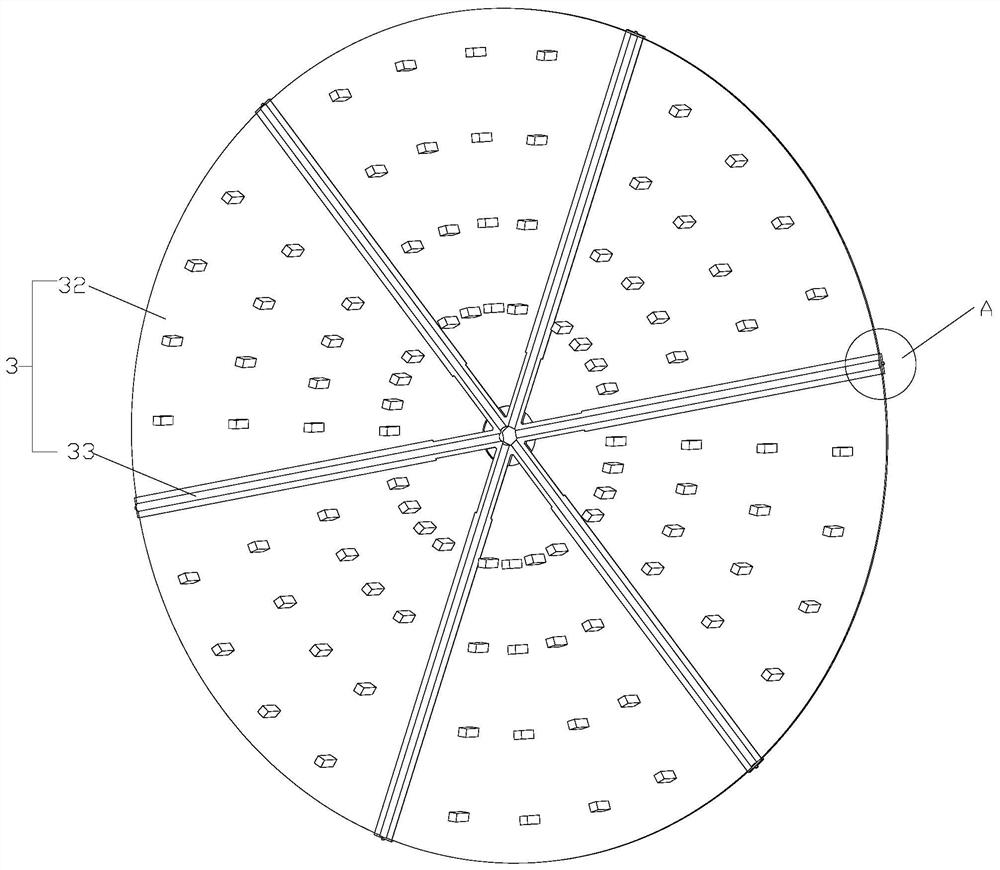

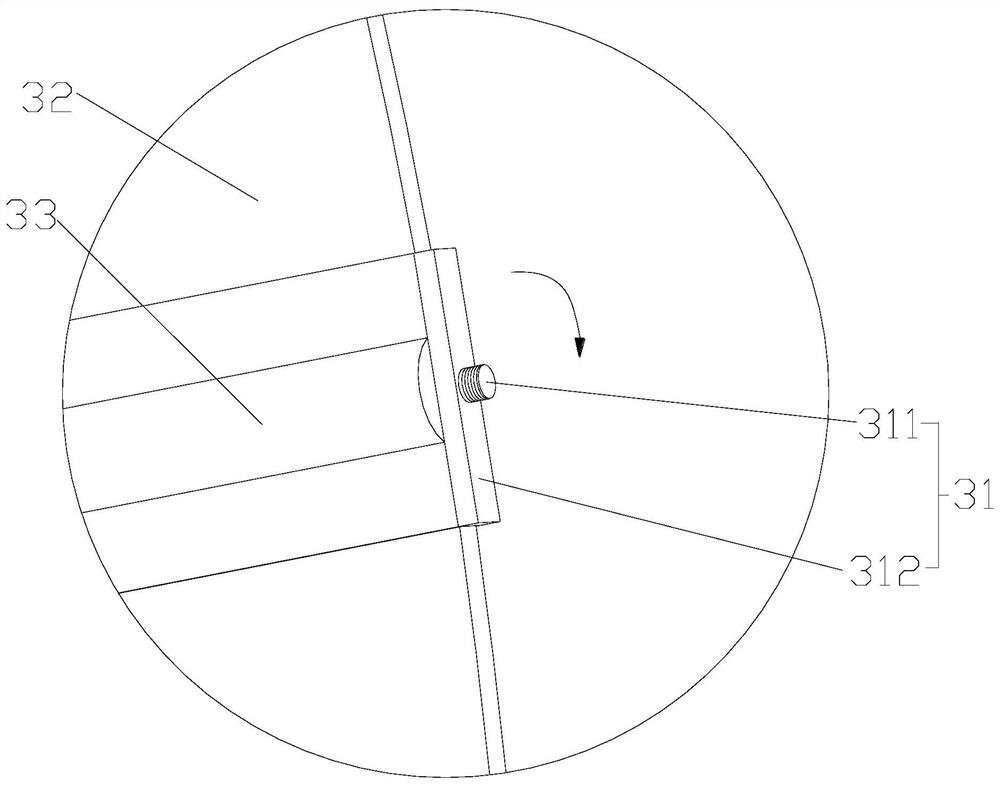

[0041] Such as Figure 1-7As shown, the polishing machine of the present invention includes a cylinder body 1, a rotating shaft 2 arranged laterally in the cylinder body 1 and rotatably connected to the cylinder body 1, and more than one workpiece arranged in sequence along the axial direction of the rotating shaft 2 and fixedly connected to the rotating shaft 2 The mounting plate 3, the driving device 4 provided on the outside of the cylinder 1 and connected to the rotating shaft 2 for driving the rotation of the rotating shaft 2, and the polishing material 5 filled in the cylinder 1 for assisting in polishing the workpiece 6 to be polished, the workpiece The mounting plate 3 is provided with more than one workpiece positioning part 321 for installing and fixing the workpiece 6 to be polished, and the cylinder body 1 is provided with a workpiece inlet 11 and a first material door 12 for opening and closing the workpiece inlet 11; Each workpiece mounting plate 3 includes more ...

Embodiment 2

[0045] Such as Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the polishing machine includes a barrel 1, and the inner cavity of the barrel 1 is provided with two horizontally arranged and parallel rotating shafts 2, and each rotating shaft 2 is rotationally connected with the barrel 1; Each rotating shaft 2 is fixedly connected with more than one workpiece mounting plate 3 which is sequentially arranged along the axial direction of the rotating shaft 2; the cylinder body 1 is provided with a driving device 4 for driving each rotating shaft 2 to rotate, and the rotation directions of the two rotating shafts 2 are opposite, and The distance between the two rotating shafts 2 is greater than the sum of the radii of the workpiece mounting discs 3 installed on the two rotating shafts 2; the cylinder body 1 is filled with polishing material 5 for assisting in polishing the workpiece 6 to be polished, and the upper surface after the polishing material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com