A locking type building material steel bar cutting device

A cutting device and locking technology, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of difficult to control cutting size, inconvenient measurement of steel bars, inconvenient access, etc., to achieve small dimensional tolerance and convenient measurement. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

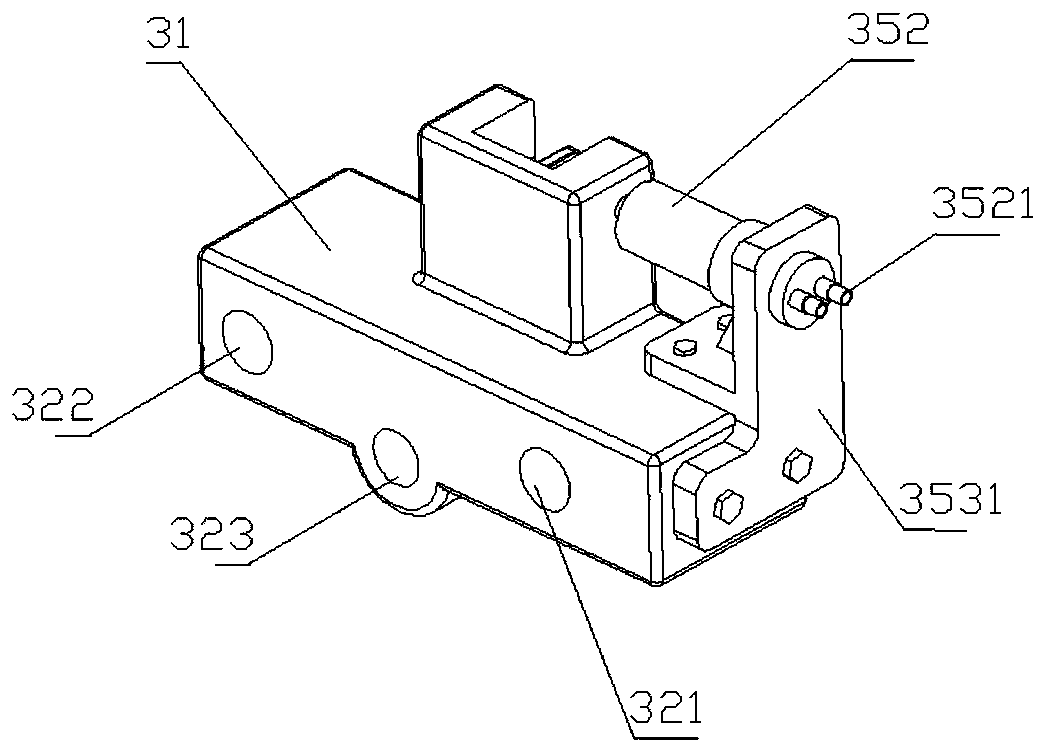

[0028] see Figure 1-Figure 9 :

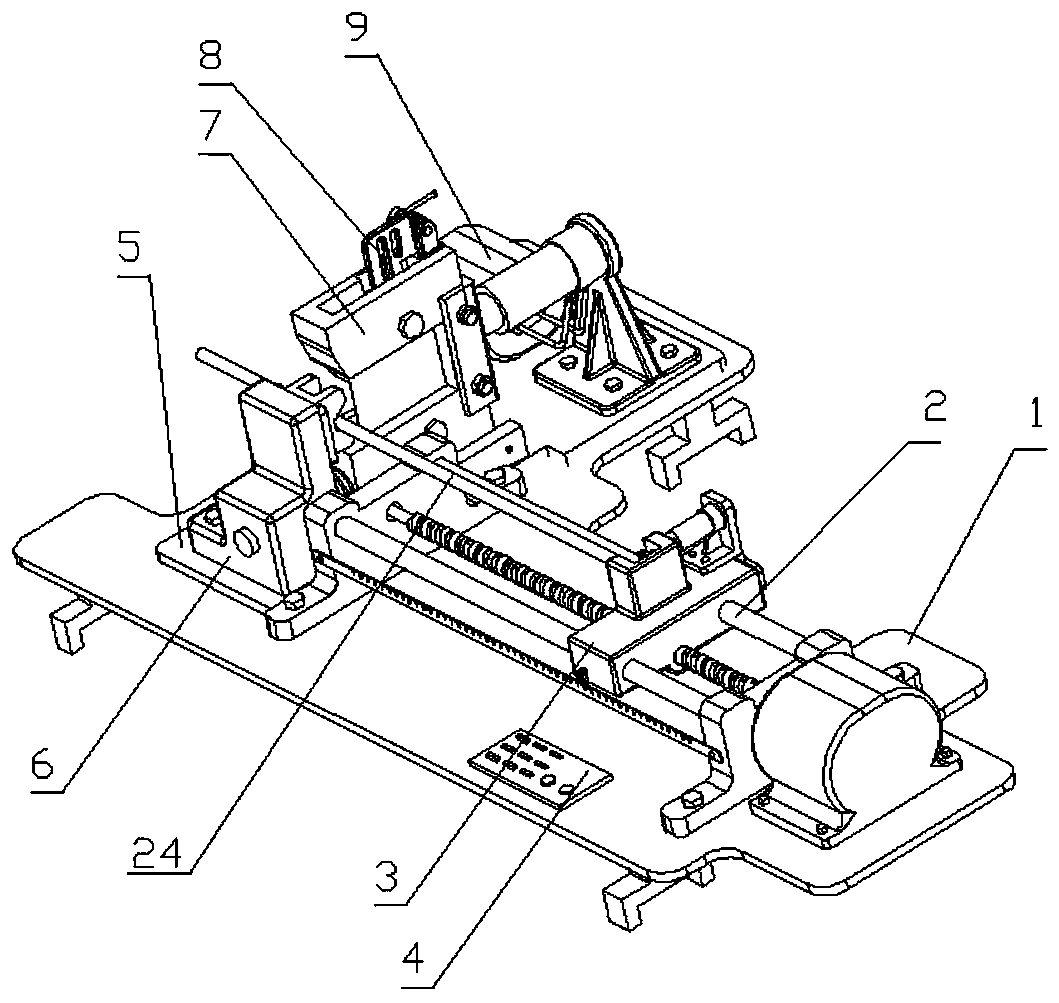

[0029] Such as figure 1 As shown, the main devices of the present invention are: bearing base 1, measuring device 2, positioner 3, control switch 4, cutting end base 5, cutting fixed end 6, cutting moving end 7, cutting blade 8, driver 9. The connection relationship of each component is from figure 1 can be clearly seen in . The bearing base 1 is an L-shaped plate-shaped structure, and a rectangular plate is extended to both vertical and horizontal sides. One side is provided with a measuring device 2 and a locator 3 on it, and the other side is provided with a cutting end base 5, which cuts the fixed end 6, and cuts The moving end 7 , the cutting blade 8 and the driver 9 are all arranged on the cutting end base 5 .

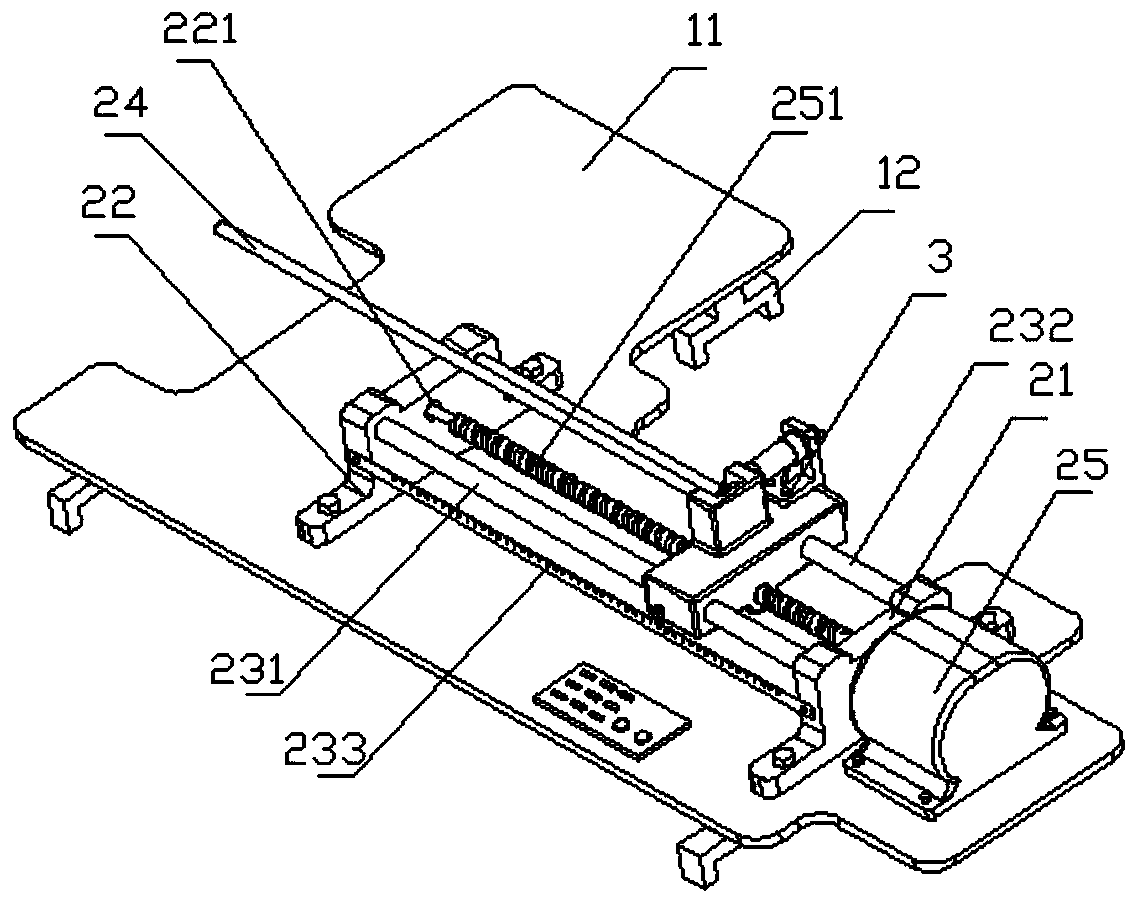

[0030] Such as figure 2 As shown, the bearing base 1 includes a base plate 11 and a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com