Steam grinding dust remover preheating device

A technology of preheating device and dust collector, which is applied in steam/steam condenser, lighting and heating equipment, grain processing, etc. It can solve the problems of material agglomeration and affecting the normal operation of the system, and achieve sufficient heat exchange, low cost and high energy efficiency. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

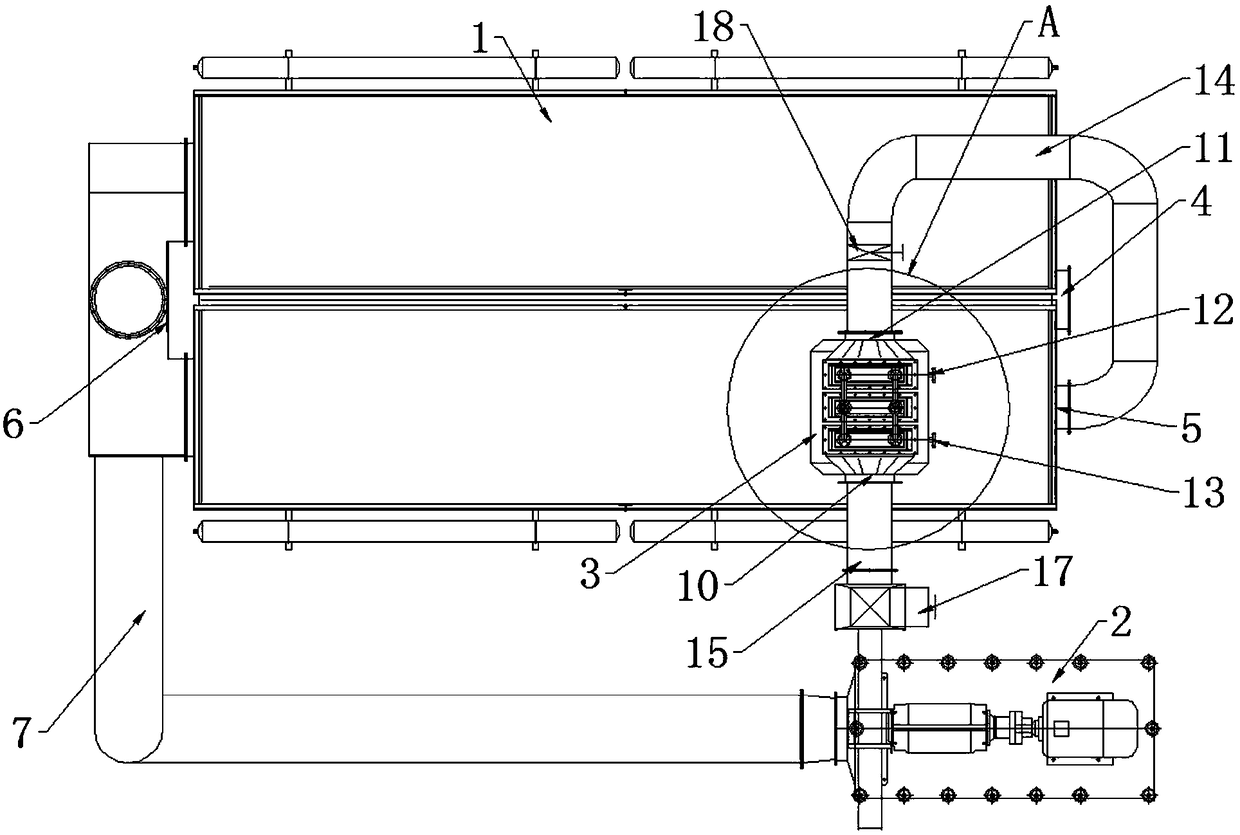

[0041] A preheating device for a steam mill dust collector, comprising a dust collector body 1, an induced draft fan 2, and a composite heat exchanger 3 connected end-to-end through pipelines, and the composite heat exchanger 3 is provided with a steam source connected to the dust collector body 1 steam inlet 12.

Embodiment 2

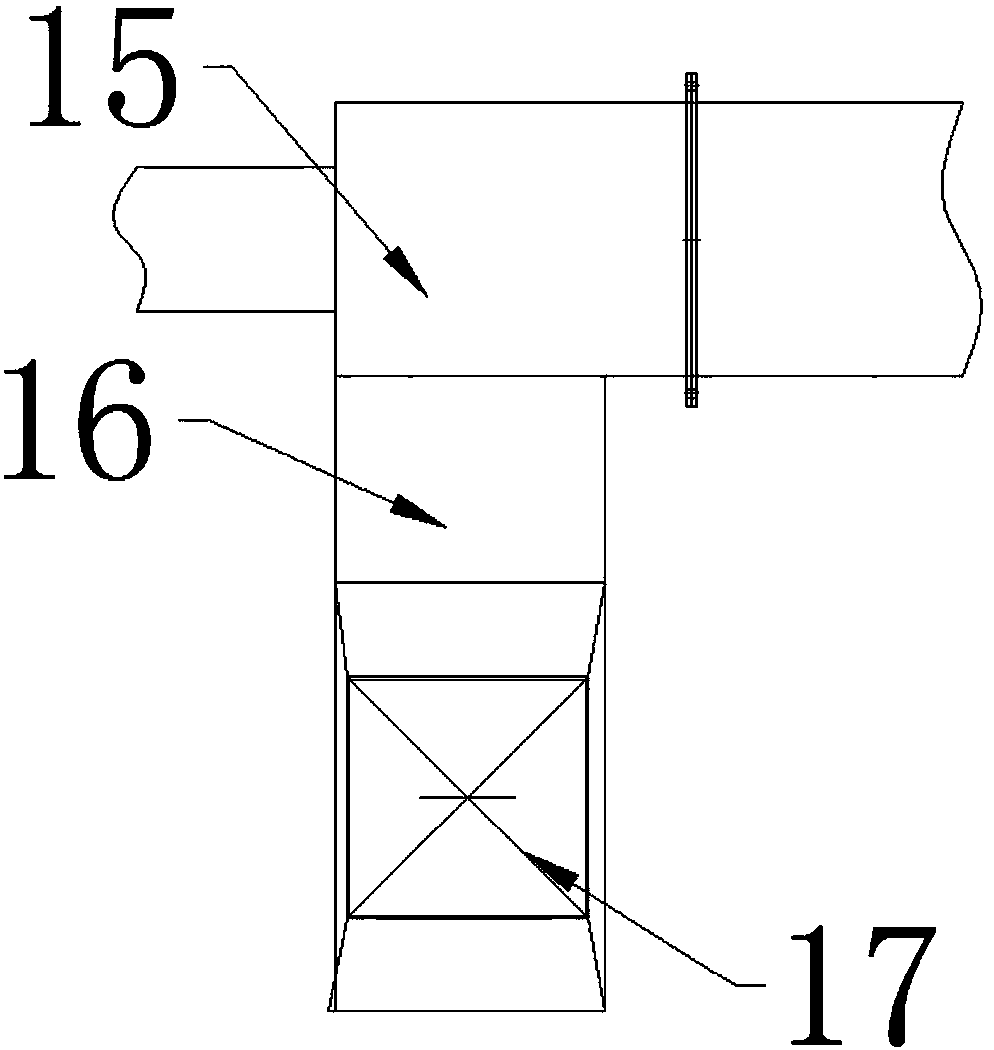

[0043] This embodiment is further optimized based on Embodiment 1. A first connecting pipe 7 is provided between the dust collector body 1 and the induced draft fan 2, and a third connecting pipe 15 is provided between the induced draft fan 2 and the composite heat exchanger 3. A second connecting pipe 14 is arranged between the compound heat exchanger 3 and the dust collector body 1, and an air outlet pipe 16 communicating with the third connecting pipe 15 is arranged below the third connecting pipe 15. On the air outlet pipe 16, There is a first valve 17, and the second connecting pipe 14 is provided with a second valve 18, which can flexibly switch the system between the negative pressure induced air mode and the internal circulation air supply mode, which is convenient to use and can make full use of preheating The duct is used for ventilation, and no additional ventilation duct is required.

Embodiment 3

[0045] This embodiment is further optimized based on Embodiment 1 or 2. The dust collector body 1 is provided with a dust collector air inlet 4, a hot air inlet 5 and a dust collector air outlet 6. The first connecting pipe 7 is arranged at the dust collector outlet. Between the tuyere 6 and the outlet of the induced draft fan 2;

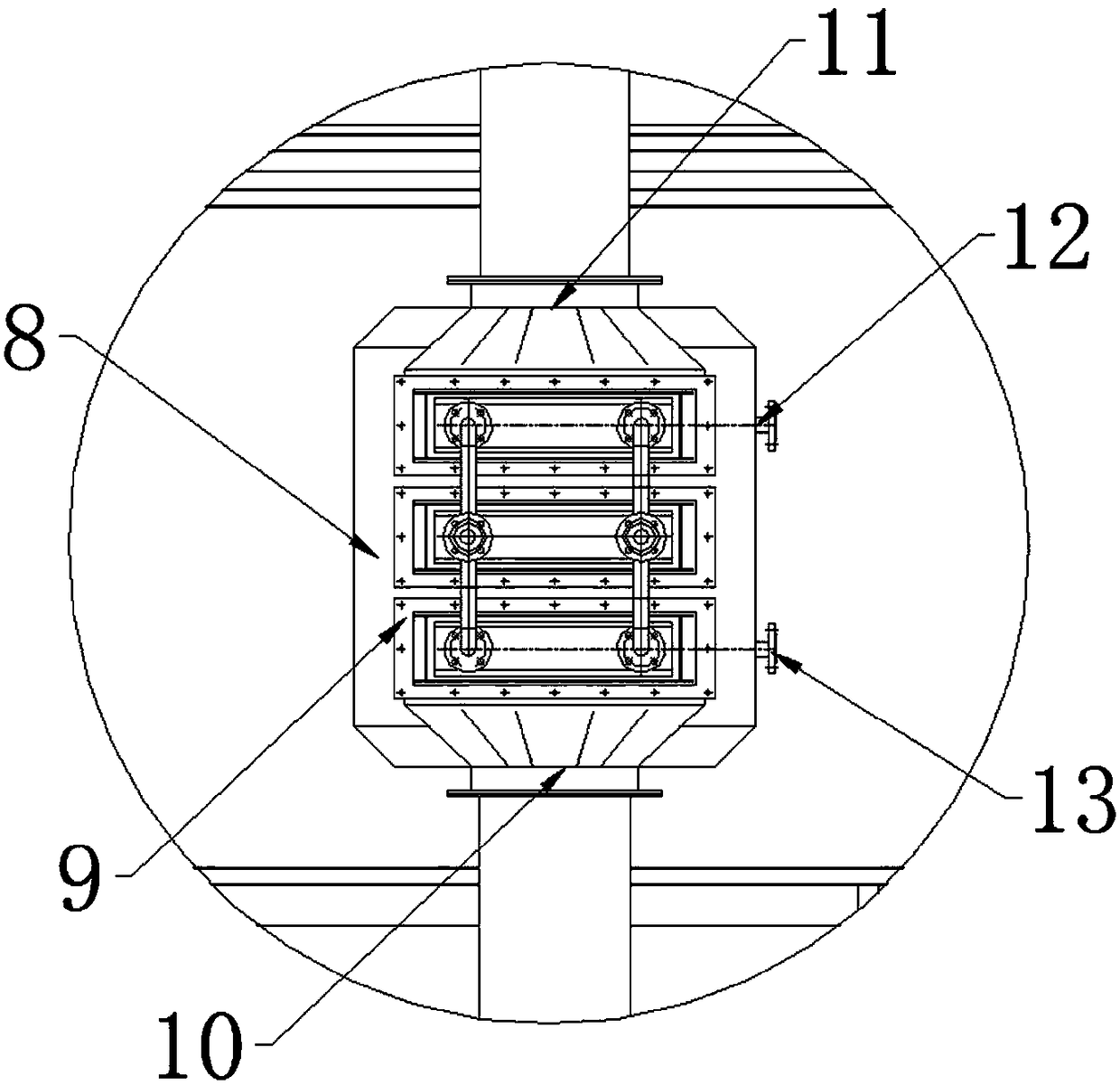

[0046]The composite heat exchanger 3 includes a circulating air chamber 8 and a heat exchange tube 9 arranged inside the circulating air chamber 8, the composite heat exchanger 3 is respectively provided with a cold air inlet 1 and a hot air outlet 11, and the cold air inlet 1 and the hot air outlet 11 are both It communicates with the circulating air chamber 8; the composite heat exchanger 3 is provided with a condensed water outlet 13, and the steam inlet 12 and the condensed water outlet 13 are both communicated with the heat exchange tube 9;

[0047] The second connecting pipe 14 is arranged between the hot air outlet 11 and the hot air inlet 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com