Isolation type composite cable

A composite cable and isolation type technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of poor moisture-proof effect, poor shielding effect of ordinary composite cables, and poor mechanical properties, so as to achieve good shielding effect and improve anti-corrosion ability , the effect of simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

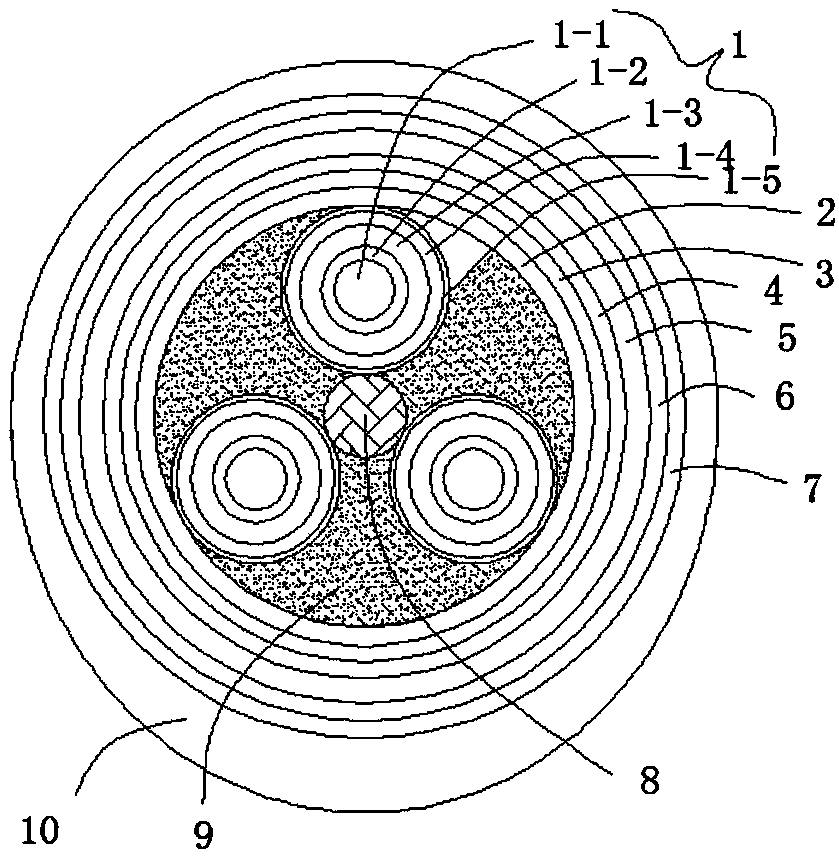

[0018] This embodiment provides an isolated composite cable, which includes 1 reinforcing core 8 and 3 cable core wires 1, and the outside of the 1 reinforcing core 8 and 3 cable core wires 1 are sequentially wrapped with loose sleeve layer 2, inner Shielding layer 3, water-proof layer 4, copper tape shielding layer 5, isolation layer 6, PVC outer sheath layer 7 and outer wear-resistant layer 10, the gaps in the loose sleeve layer 2 are filled with water-blocking paste, and the outer The thickness of the upper end of the grinding layer 10 is smaller than that of the lower end, and the material of the isolation layer 6 is an inorganic mineral insulating layer.

[0019] The cable core wire 1 includes a power core conductor 1-1 and a conductor shielding layer 1-2, an insulating layer 1-3, an insulating shielding layer 1-4 and a sheath layer 1-1 arranged outside the power core conductor 1-1 in sequence. 5.

[0020] The material of the isolation layer 6 is magnesium oxide.

[002...

Embodiment 2

[0024] This embodiment has been further optimized on the basis of Embodiment 1 and is specifically:

[0025] The inner shielding layer 3 is a silver-plated braided copper mesh layer arranged along the line length direction of the cable. mesh layer.

[0026] The reinforcing core 8 is made of galvanized steel wire with a diameter of 0.2-0.3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com