Energy-saving waterproof roll laying device for highways and tunnels

A waterproofing membrane and laying device technology, applied in tunnels, tunnel linings, transmission devices, etc., can solve the problem of inability to accurately control the length and speed of rewinding and unwinding of waterproofing membranes, construction quality and speed effects, and inability to accurately calculate length, etc. problems, to achieve the effect of improving transfer efficiency and accuracy, low buffer performance, and saving repeated adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

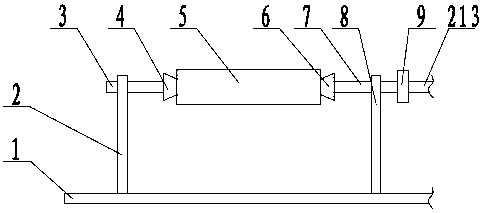

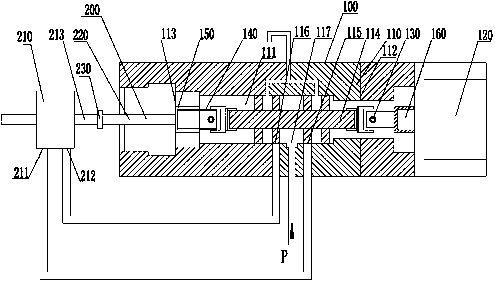

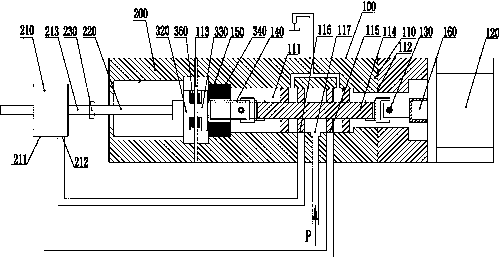

[0025] Such as figure 1 As shown, the energy-saving waterproof membrane laying device for roads and tunnels includes a bottom plate 1, a left bracket 2, a left top column 3, a left clamping block 4, a waterproof coiled material reel 5, a right clamping block 6, and a right turning rod 7. The right bracket 8, the first coupling 9 and the internal drive feedback digital hydraulic cylinder 10, the left bracket 2 and the right bracket 8 are both fixedly arranged on the bottom plate 1, and the left jacking column 3 is rotated and set by a one-way bearing On the left bracket 2, the right turning rod 7 is arranged on the right bracket 8 through the bearing, the left clamping block 4 is provided at one end of the left push-up column 3, the right locking block 6 is arranged at one end of the right rotating rod 7, and the left locking block 4 right The clamping blocks 6 clamp both ends of the waterproof coiled material reel 5 together, and the other end of the right rotating rod 7 is co...

Embodiment 2

[0031] Such as figure 1 As shown, the energy-saving waterproof membrane laying device for roads and tunnels includes a bottom plate 1, a left bracket 2, a left top column 3, a left clamping block 4, a waterproof coiled material reel 5, a right clamping block 6, and a right turning rod 7. The right bracket 8, the first coupling 9 and the internal drive feedback digital hydraulic cylinder 10, the left bracket 2 and the right bracket 8 are both fixedly arranged on the bottom plate 1, and the left jacking column 3 is rotated on the left side through a bearing. Bracket 2, right turning rod 7 is arranged on right bracket 8 through bearing, and one end of left jacking post 3 is provided with left block 4, and one end of right turning rod 7 is provided with right block 6, and left block 4 is right block 6 clamp both ends of the waterproof coiled material reel 5 together, and the other end of the right rotation rod 7 is connected to the internal drive feedback digital hydraulic cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com