Single-paper-waste-cleaning and full-waste-cleaning visual automatic register device and method

A sheet-fed, waste-cleaning technology, applied in metal processing and other fields, can solve problems such as low plate efficiency and potential safety hazards, and achieve the effects of improving precision, reducing labor intensity, and reducing operational risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

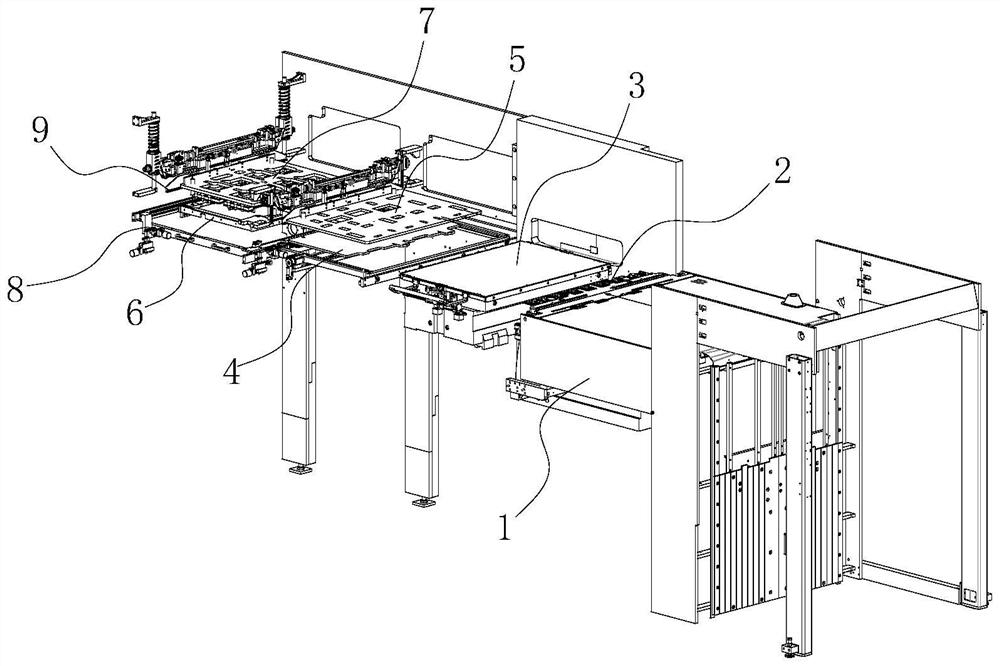

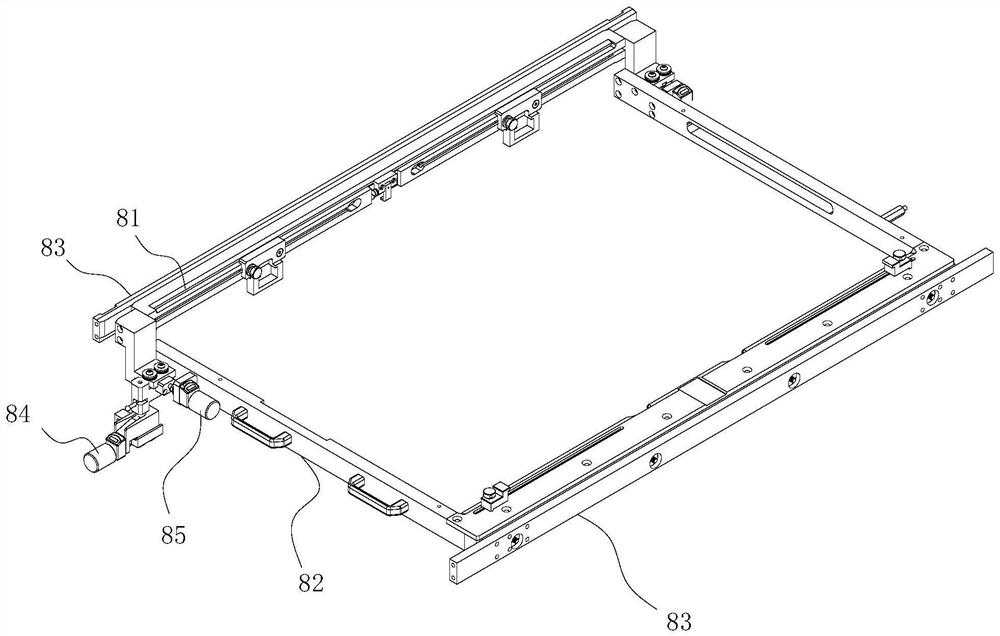

[0046] This embodiment provides a sheet-fed stripping and full stripping visual automatic plate alignment device, including an electrically adjustable negative stripping board, a lower box divider, an upper stripping board, and an upper box divider;

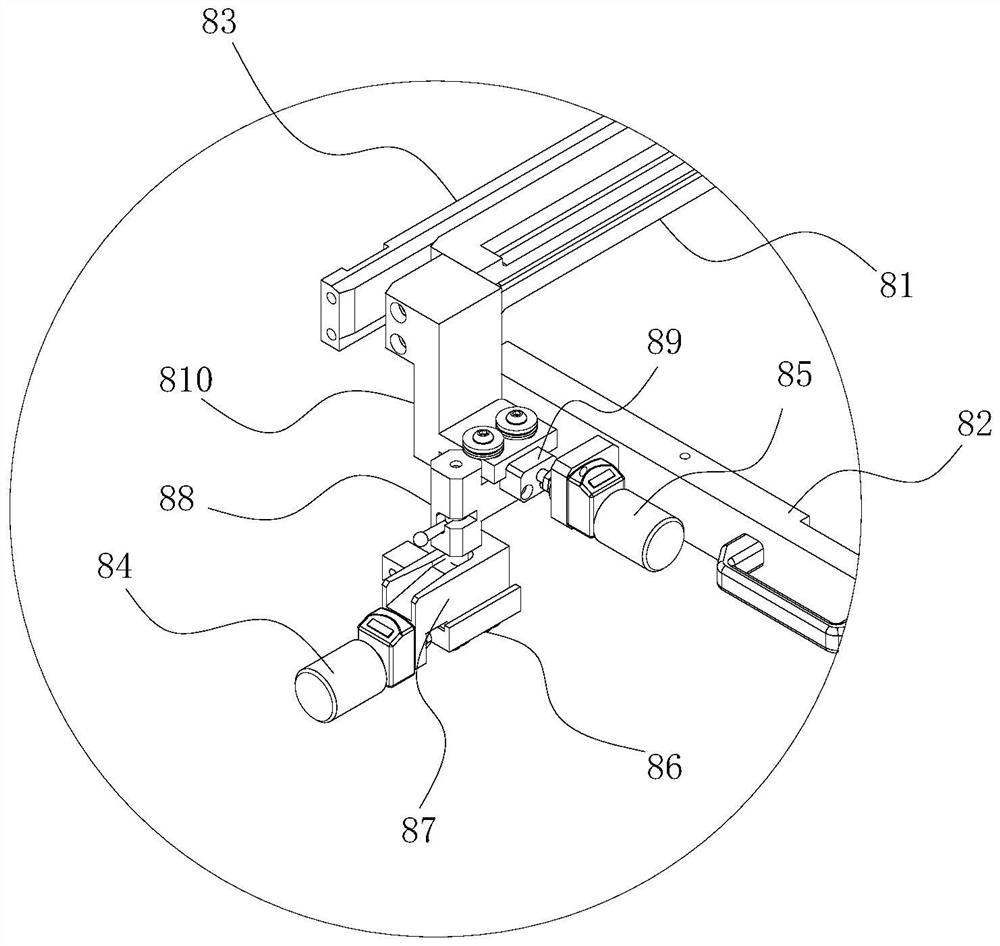

[0047] One of the negative stripping plate and the upper stripping plate is equipped with a detection mark, and the other is equipped with a visual detection unit. After the position adjustment of the negative stripping plate is completed, adjust the position of the upper stripping plate according to the relative position of the detection mark and the visual detection unit. position so that it corresponds to the position of the negative stripping board;

[0048] One of the lower box divider and the upper box divider is equipped with a detection mark, and the other is equipped with a visual detection unit. After the position adjustment of the lower box divider is completed, adjust the position of the upper box divider according to ...

Embodiment 2

[0073] This embodiment provides a plate alignment method applied to the single-fed stripping and full stripping visual automatic plate alignment device of the above embodiment, including the following steps:

[0074] Determine the difference between the new product and the original product, and obtain the offset that needs to be adjusted based on the difference;

[0075] Control the operation of the motor based on the offset to adjust the position of the negative stripping plate and the lower box divider to correspond to the new product;

[0076] After the position adjustment of the negative stripping board and the lower box divider is completed, the visual inspection unit adjusts the positions of the upper stripping board and the upper box divider based on the front and rear position movement of the detection mark, so that they are in line with the negative stripping board and the lower box divider. corresponding to the position.

[0077] Electronic registration uses sensors t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap