Method for preparing ultra-high-purity volatile rare earth cerium chelate

A chelate, high-purity technology, applied in the field of CVD, can solve the problems of difficult separation and purification, low yield, and difficulty in preparing β-diketone rare earth cerium, so as to improve purity, high yield, control the introduction of impurities and side effects The effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] Rare earth cerium raw material processing:

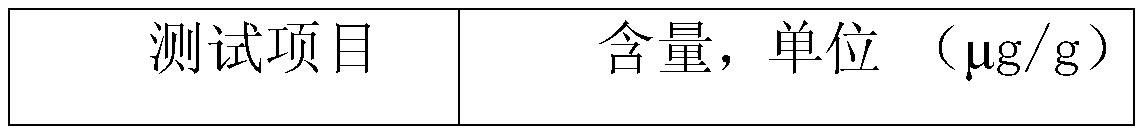

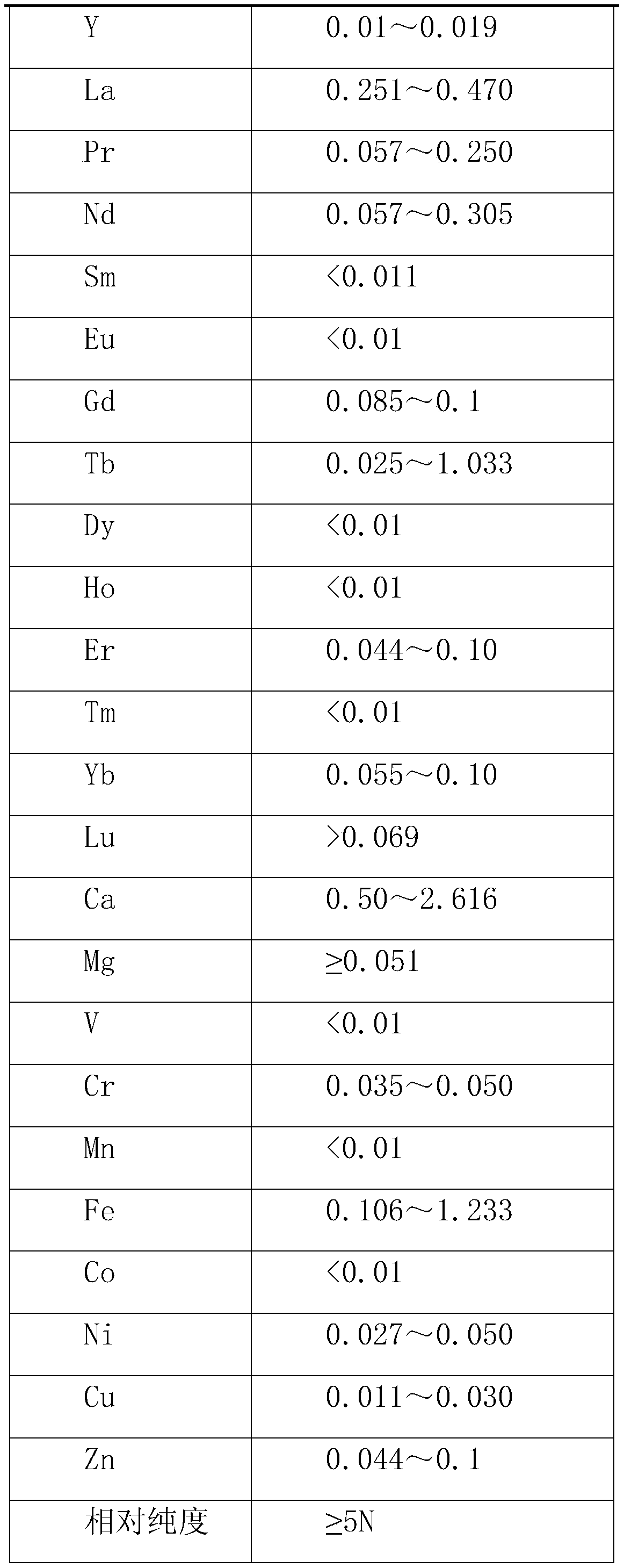

[0048] The purity of Ce(NO 3 ) 3 Raw materials are processed by ion exchange method to obtain high purity CeO 2 Raw material (relative purity> 5N), the ICP-MS analysis results of the treated cerium raw materials are as follows:

[0049]

[0050]

[0051] Dione ligand treatment:

[0052] Take the commercially available analytically pure 2,2,6,6-tetramethyl-3,5-heptanedione for distillation, collect the middle distillate, the color of the obtained ligand is colorless, GC-MS analysis, after processing 2, 2,6,6-Tetramethyl-3,5-heptanedione content> 99%, ICP-MS analysis showed that the content of Fe in the ligand was reduced from 154.9ppb to 60ppb, and the content of Mg was reduced from 137ppb to <10ppb.

[0053] Preparation of high purity cerium chelate (tetramethyl-2,2,6,6-tetramethyl-3,5-heptanedione cerium chelate) 1:

[0054] ①Take 7.45g of CeO obtained after treatment 2 In the beaker, then add 1M treated HNO 3 10ml, stir overnight an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com