Grinding fog type PP film which has easiness in heat seal and can be internally printed and preparation method

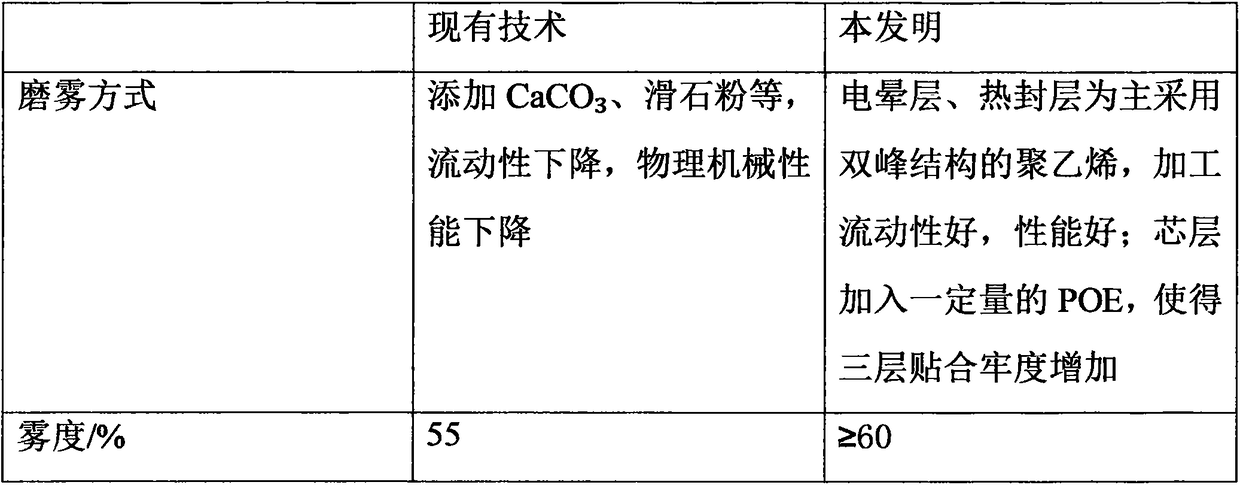

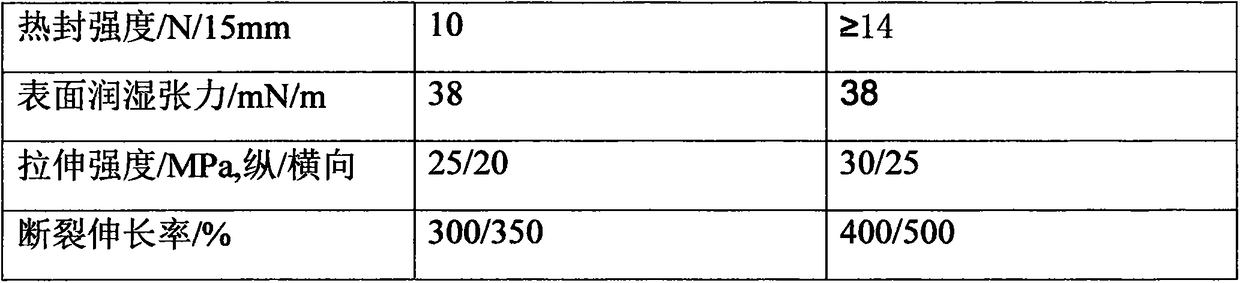

A film and heat-sealing layer technology, applied in the field of packaging materials, can solve the problems of poor film heat-sealing performance, poor film heat-sealing performance, poor processing fluidity, etc., and achieve the effect of good heat-sealing performance and good fogging effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

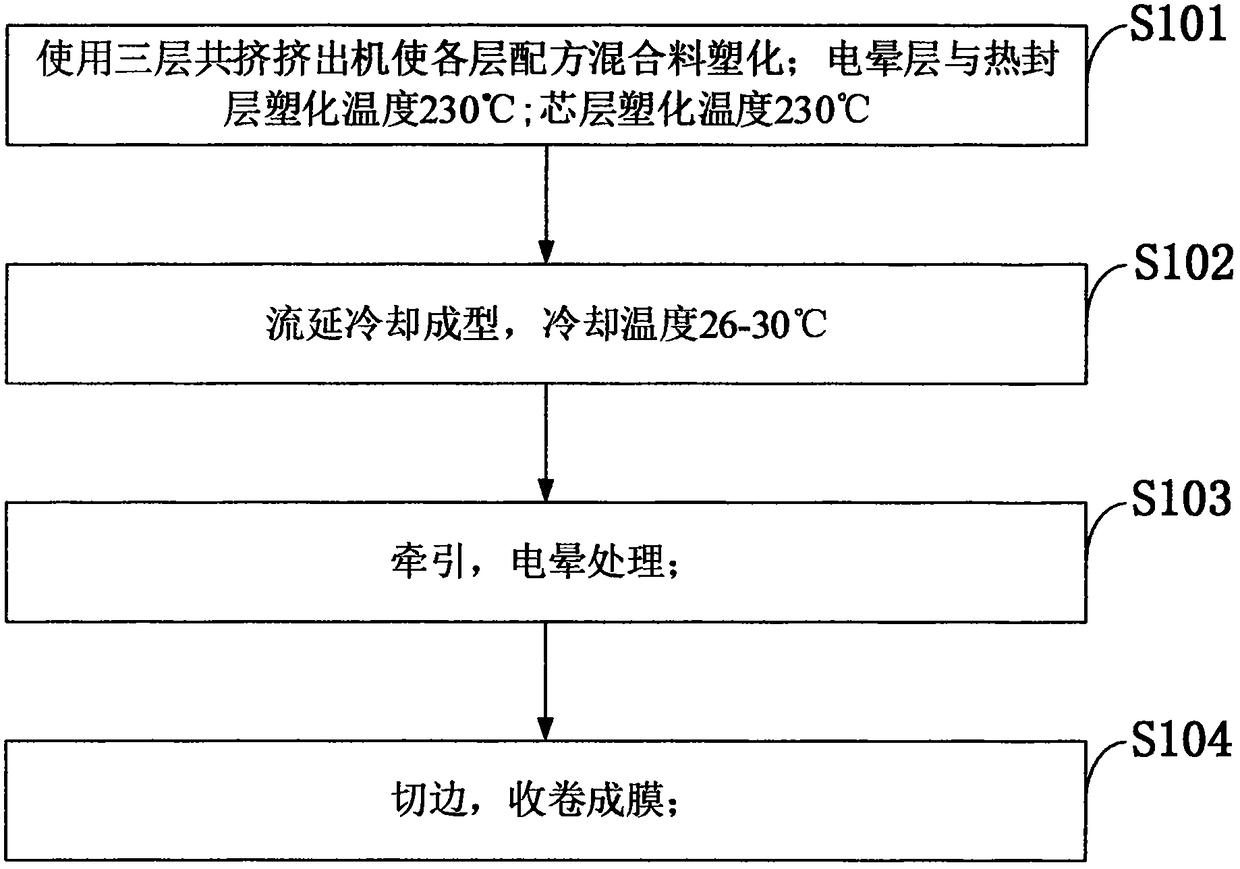

[0026] Such as figure 1 As shown, in view of the problems existing in the prior art, the method for preparing the mist-type easily heat-sealable crepe PP film provided by the embodiment of the present invention includes:

[0027] S101: Use a three-layer co-extrusion extruder to plasticize the formulation mixture of each layer; the plasticizing temperature of the corona layer and the heat-sealing layer is 230°C; the core layer is 230°C.

[0028] S102: Cast cooling molding, cooling temperature 26-30℃;

[0029] S103: Traction, corona treatment;

[0030] S104: Trimming and winding into film.

Embodiment 1

[0032] The corona layer is composed of 85 parts of bimodal PE, 15 parts of binary copolymer polypropylene, 0.5 parts of slip agent, 1.5 parts of opening agent and 0.5 parts of antistatic agent in terms of mass fraction;

[0033] The core layer is made of 85 parts of homopolypropylene and 15 parts of POE in terms of mass fraction;

[0034] The heat-sealing layer is composed of 100 parts of bimodal PE, 1.5 parts of slip agent, 0.5 part of opening agent and 0.5 part of antistatic agent in terms of mass fraction;

[0035] Use a three-layer co-extrusion extruder to plasticize the formulation mixture of each layer. The corona layer and the heat-seal layer are plasticized at 230°C, the core layer is at 230°C, and the cooling temperature is 30°C. Corona treatment, trimming, winding into film.

Embodiment 2

[0037] The corona layer uses 43 parts of bimodal PE, 57 parts of binary copolymer polypropylene, 0.7 parts of slip agent, 0.8 parts of opening agent and 0.7 parts of antistatic agent in terms of mass fraction;

[0038] The core layer uses 92 parts of homopolypropylene and 8 parts of POE in terms of mass fraction;

[0039] The heat-sealing layer uses 100 parts of bimodal PE, 0.8 parts of slip agent, 0.7 parts of opening agent and 0.7 parts of antistatic agent in terms of mass fraction;

[0040] Use a three-layer co-extrusion extruder to plasticize the formulation mixture of each layer. The corona layer and the heat-seal layer are plasticized at 230°C, the core layer is plasticized at 235°C, and the cooling temperature is 26°C. Corona treatment, trimming, winding into film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com