Letter box equipment

A device and letter box technology, applied in metal processing equipment, grinding/polishing equipment, grinders, etc., can solve the problems of low work efficiency and the harm of debris to the human body, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

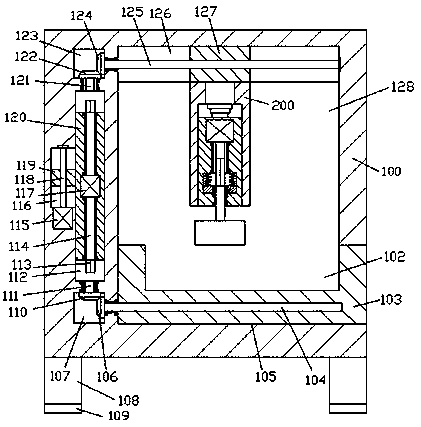

[0011] Combine below Figure 1-3 The present invention will be described in detail.

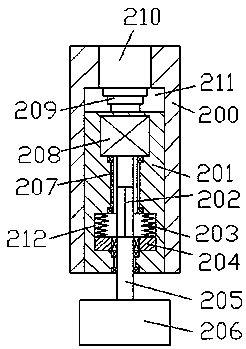

[0012] refer to Figure 1-3, a letterbox device according to an embodiment of the present invention, comprising a main seat frame 100, four corners of the bottom end surface of the main base body 100 are fixed with columns 108, and the bottom end surface of the column 108 is fixed with foot pads 109 , the inner wall of the main seat frame 100 is provided with a storage cavity 128, the top wall of the storage cavity 128 is provided with a first sliding connection cavity 126, and the bottom wall of the storage cavity 128 is provided with a second sliding connection cavity. The connecting cavity 105, the second sliding connecting cavity 105 runs through the right end surface of the main seat frame 100, the mounting seat 103 is installed in the second sliding connecting cavity 105, and the left end surface of the mounting seat 103 is internally threaded. A first screw rod 104 is installed, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com