Soil grinding centrifugal type sieving machine

A centrifugal and centrifugal sieve technology, which is applied in the direction of solid separation, material analysis, and separation of solids from solids with airflow, etc., can solve problems such as great impact on health, low work efficiency, and poor data accuracy, and achieve soil High sample screening precision, low labor intensity, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

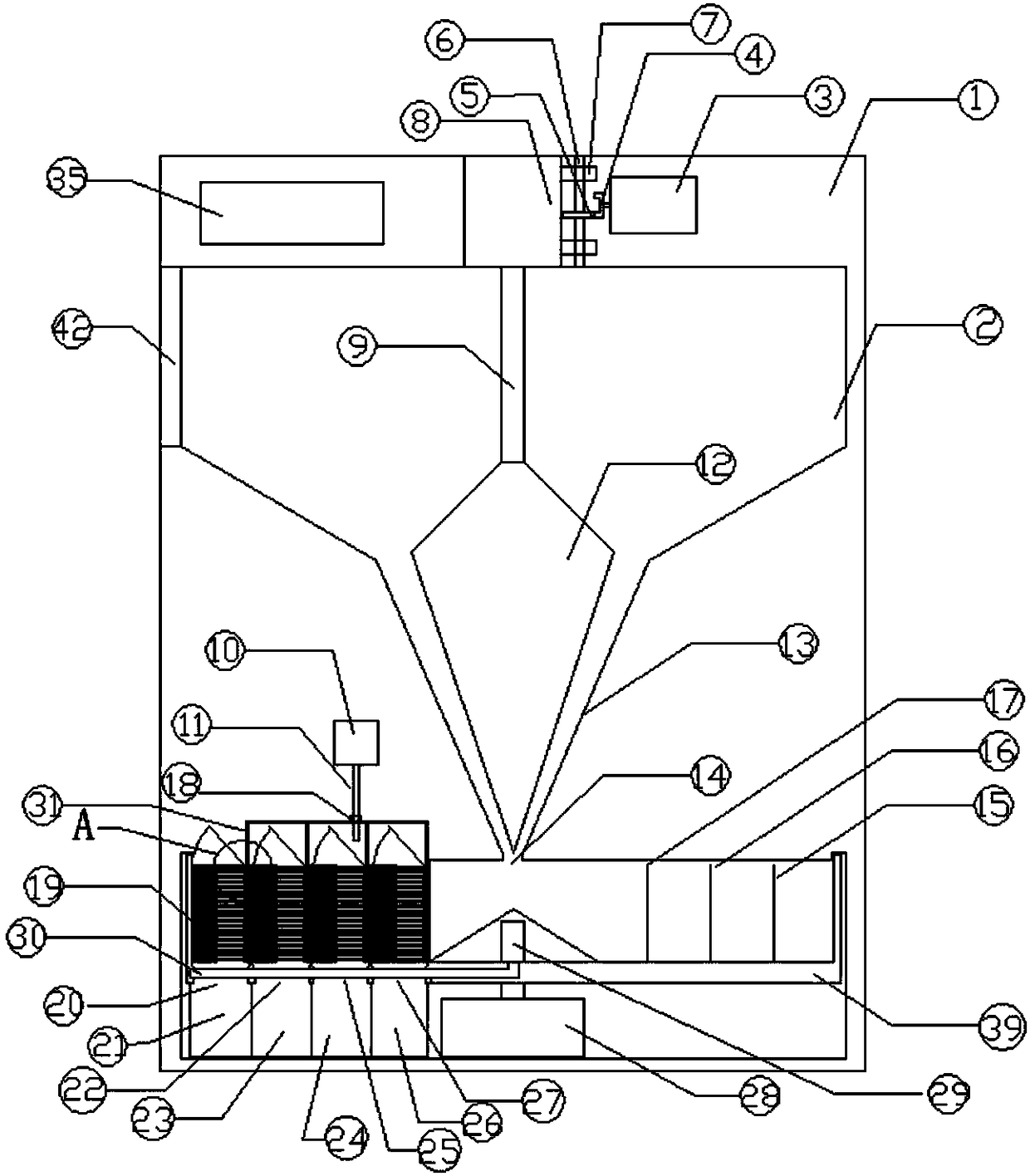

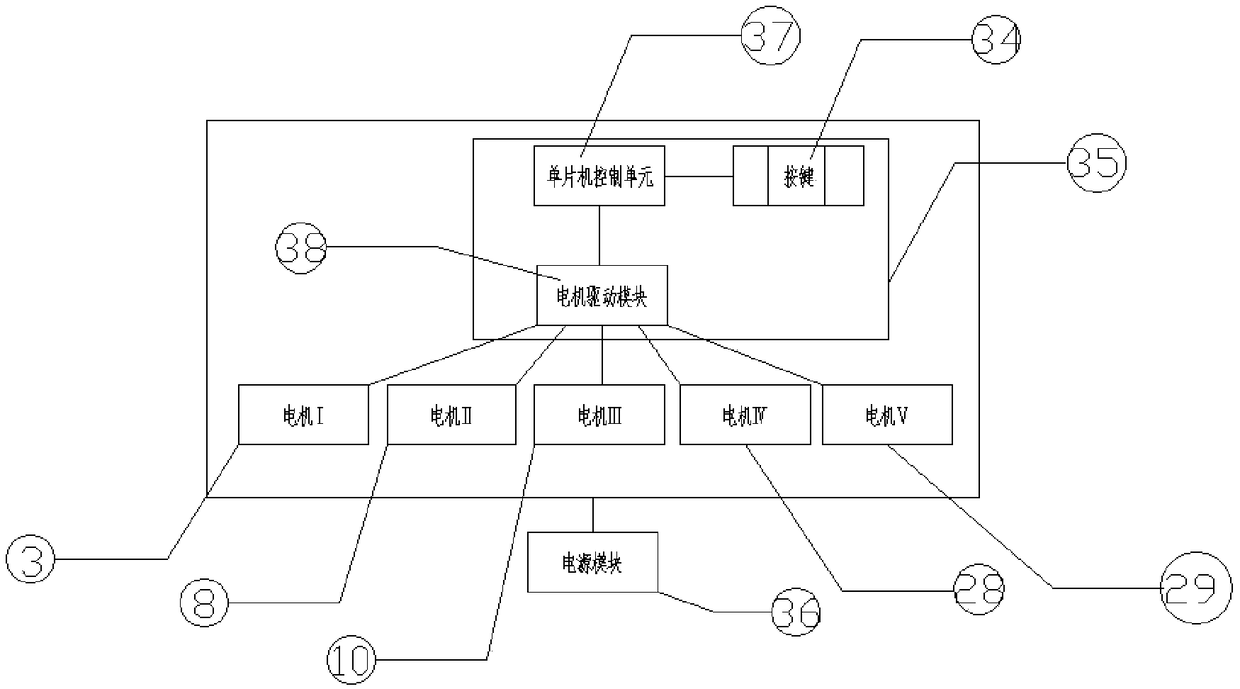

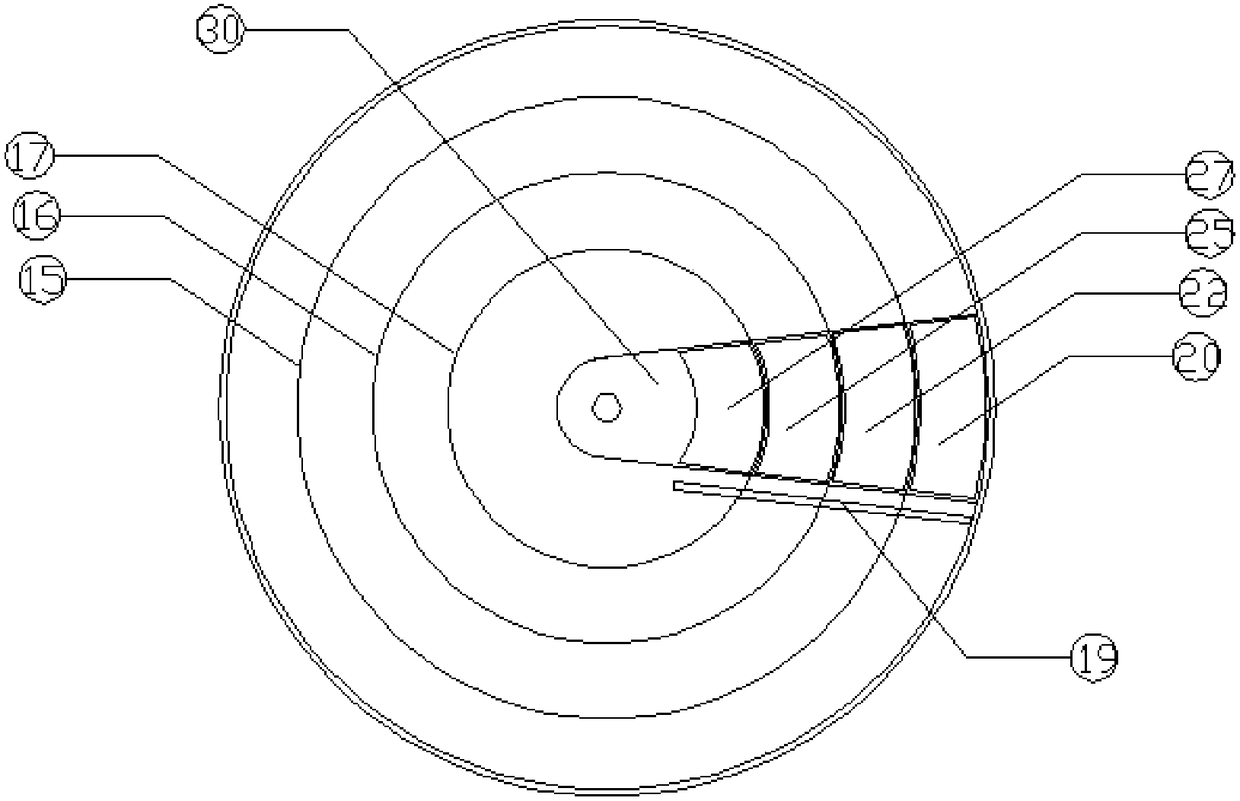

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A kind of equipment that integrates soil grinding and centrifugal screening, including grinding and centrifugal screening devices. It is characterized in that: motor I3, gear I4, gear II5, and cantilever 7 are sequentially installed on the top of the feeding chamber 2 inside the machine housing 1. , the screw rod I6 and the motor II8, wherein the motor I3 is fixed with the gear I4, the gear I4 is meshed with the gear II5, the cantilever 7 is fixed with the motor II8, and the thread on the screw rod I6 cooperates with the internal thread of the gear II5 to move up and down The mobile motor II8 is fixedly connected to the grinding cone 12 through the connecting rod IV9 at the bottom end of the mobile motor II8. The feeding chamber 2 is surrounded by the grinding surface 13, the feeding port 14, and the feeding port 42. The feeding port 14 Turntable 39 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com