Precursor solution and method for preparing same, preparation of solar cell electron transport layer, and solar cell

An electron transport layer and solar cell technology, applied in the field of solar cells, can solve the problems of increasing the production cost of cells and unfavorable development of flexible cells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

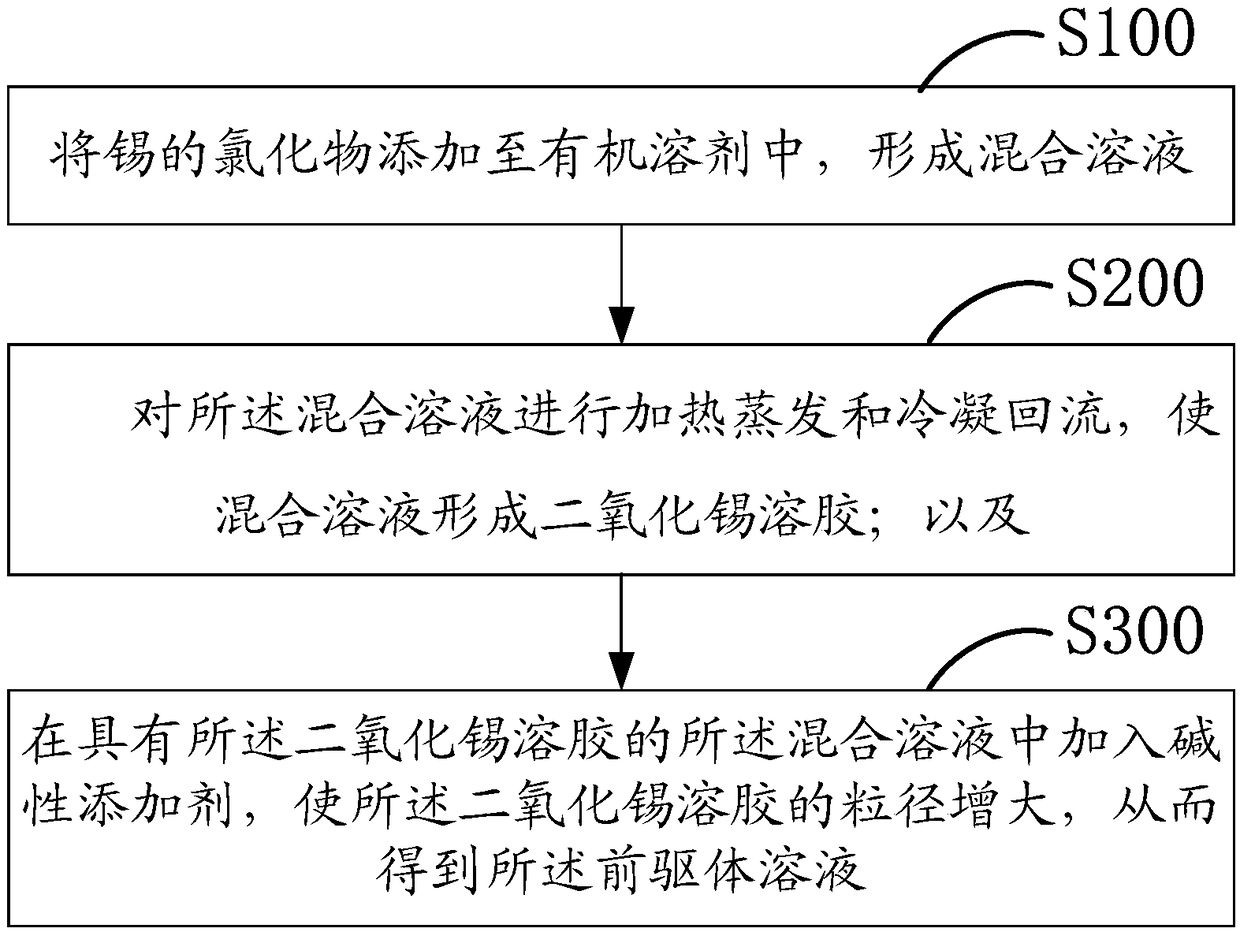

[0039] see figure 1 , an embodiment of the present invention provides a method for preparing a precursor solution for preparing an electron transport layer of a solar cell, comprising:

[0040] S100, adding tin chloride to an organic solvent to form a mixed solution;

[0041] S200, heating, evaporating and condensing the mixed solution to reflux, so that the mixed solution forms a tin dioxide sol; and

[0042] S300, adding an alkaline additive to the mixed solution containing the tin dioxide sol to increase the particle size of the tin dioxide sol, thereby obtaining a precursor solution.

[0043] The preparation method of the precursor solution for preparing the electron transport layer of the solar cell provided by the embodiment of the present invention adopts the combination of reflux and alkaline additive control, firstly makes the mixed solution form a sol by reflux, and then adds the alkaline additive, Increase the particle size to obtain the required precursor solutio...

Embodiment 1

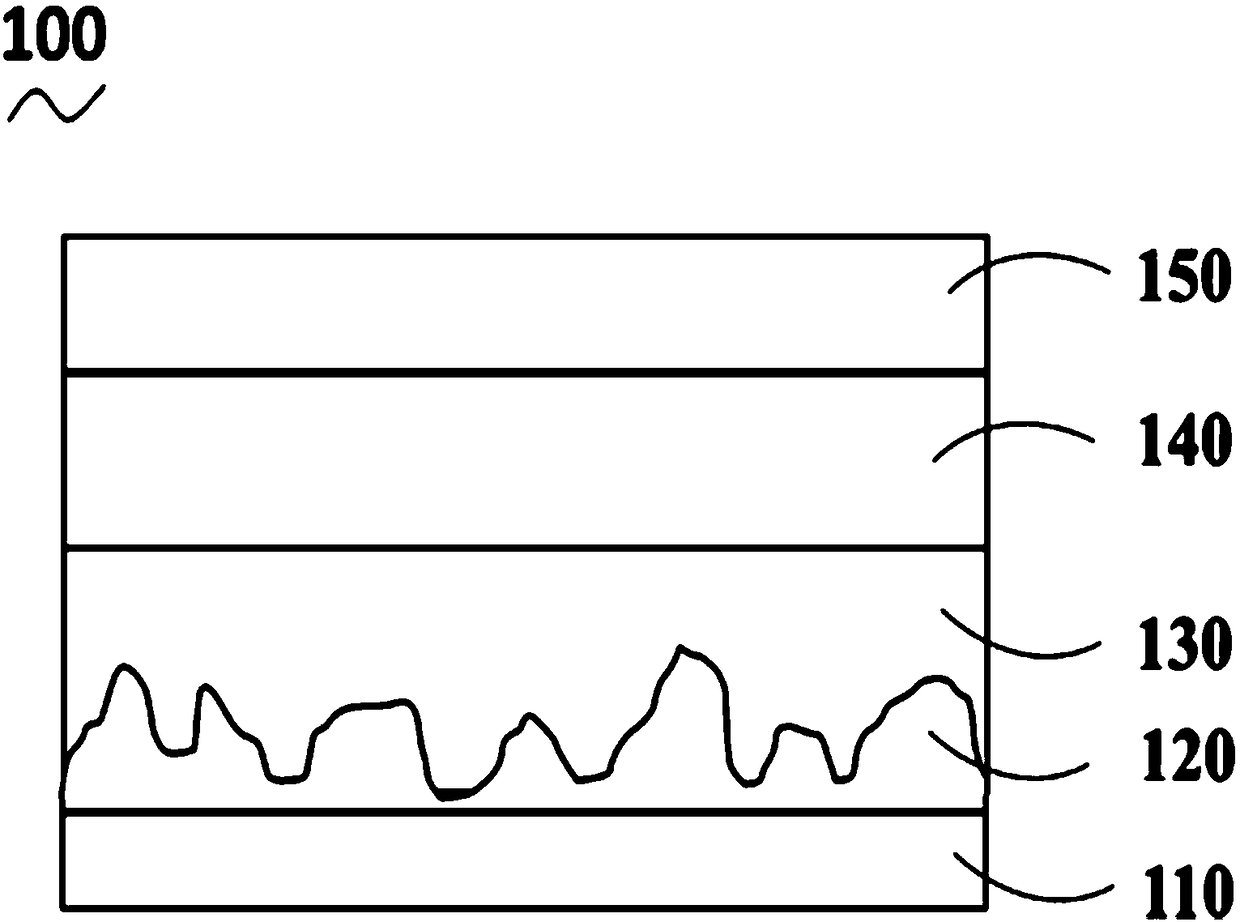

[0069] Example 1 Rigid micro-nano structure SnO 2 Fabrication of perovskite-based solar cells

[0070] Preparation of the electrode plate 110: partially etch the transparent conductive FTO glass with Zn powder and HCl, and partially protect it. After the etching is completed, it is cleaned with deionized water, ethanol, acetone, and isopropanol in sequence, and then dried for use.

[0071] Preparation of precursor solution: SnCl 2 ·H 2 O is dissolved in absolute ethanol to form a mixed solution, and the SnCl in the mixed solution 2 The molar concentration is 0.1mol L -1 ; Condensate and reflux at 80°C for 3h, then stand still at 40°C for 3h to form a SnO 2 Solution of sol; add alkaline additive NH 3 ·H 2 O, stir evenly to obtain the precursor solution, the alkaline additive NH in the precursor solution 3 ·H 2 The molar content of O is 0.01mol L -1 .

[0072] Prepare the electron transport layer 120: drop the precursor solution on the FTO conductive glass substrate, s...

Embodiment 2

[0077] Example 2 Flexible micro-nano structure SnO 2 Fabrication of perovskite-based solar cells

[0078] The preparation method is basically the same as that of Example 1, except that the flexible ITO / PEN conductive substrate is selected as the electrode plate 100 .

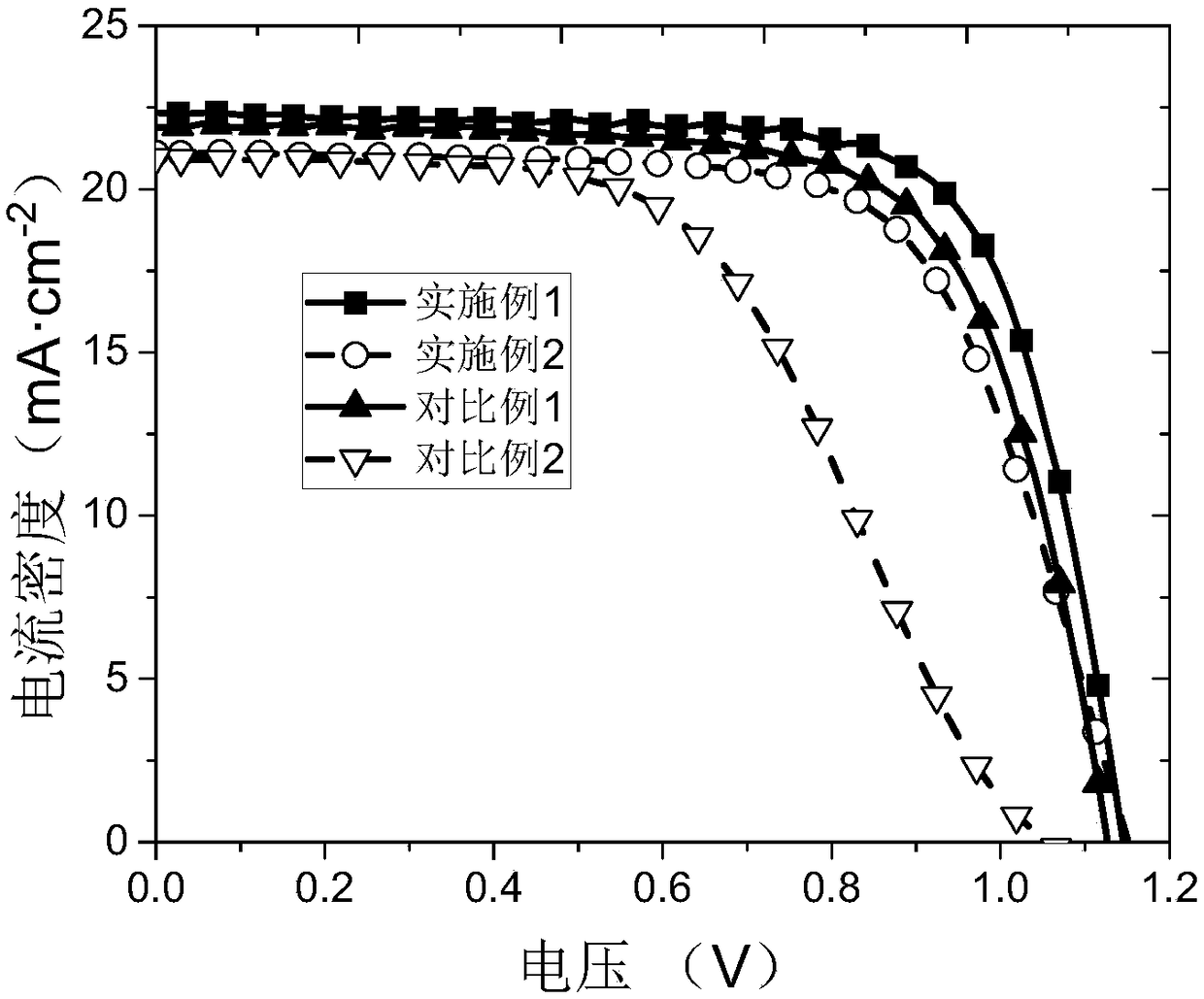

[0079] The battery is AM1.5, 100mW / cm 2 Test the J-V performance curve of the battery with a Keithley 24 million multimeter under light. see image 3 According to the curve of Example 2, the short-circuit current density of the battery is 21.19mA / cm 2 , the open circuit voltage is 1.14V, the fill factor is 0.68, and the photoelectric conversion efficiency is 16.42%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com