3d NAND memory and its manufacturing method

A 3DNAND, memory technology, applied in semiconductor devices, electric solid devices, electrical components, etc., can solve the problems of low storage density of 3DNAND memory, poor electrical performance of 3DNAND memory, unstable distribution range of read current, etc., and reach the current fluctuation range. Small, high carrier mobility and speed, the effect of stable read current ID

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

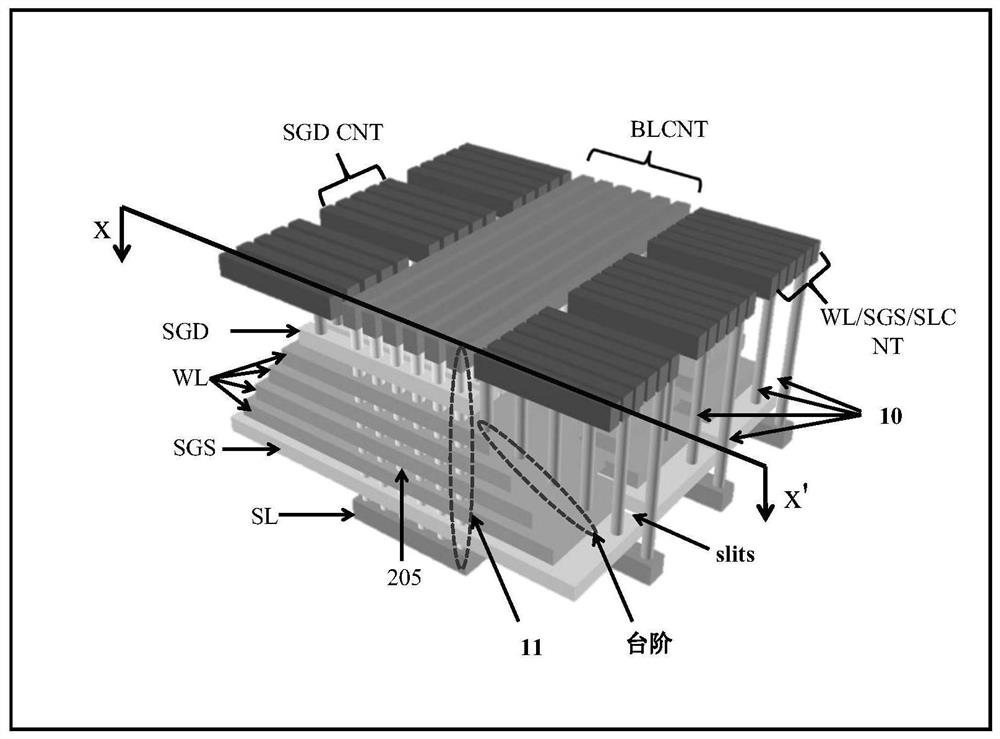

[0057] Before introducing the specific embodiments of the present application, the Chinese and English translations and abbreviations of technical terms used in describing the specific embodiments of the present application are firstly introduced.

[0058] Atomic layer deposition: atom layer deposition, ALD;

[0059] Chemical vapor deposition: chemical vapor deposition, CVD;

[0060] Physical vapor deposition: Physical Vapor Deposition, PVD;

[0061] Source selection gate: Select Gate on Source Side, SGS;

[0062] Drain selection gate: Select Gate on Drain Side, SGD;

[0063] Bit line: bit line, BL;

[0064] Word line: word line, WL;

[0065] Source: source line, SL.

[0066] Based on the background technology, it can be seen that the existing 3D NAND memory has the following problems: poor electrical performance, low read / write efficiency, and low storage density.

[0067]The inventors of the present application have discovered through research that the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com