Manufacturing method of film cell

A thin-film battery and manufacturing method technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve problems such as increased manufacturing costs, lower yields, and cracked substrates, so as to avoid waste and avoid Unfavorable, utilization-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail through the following embodiments and in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

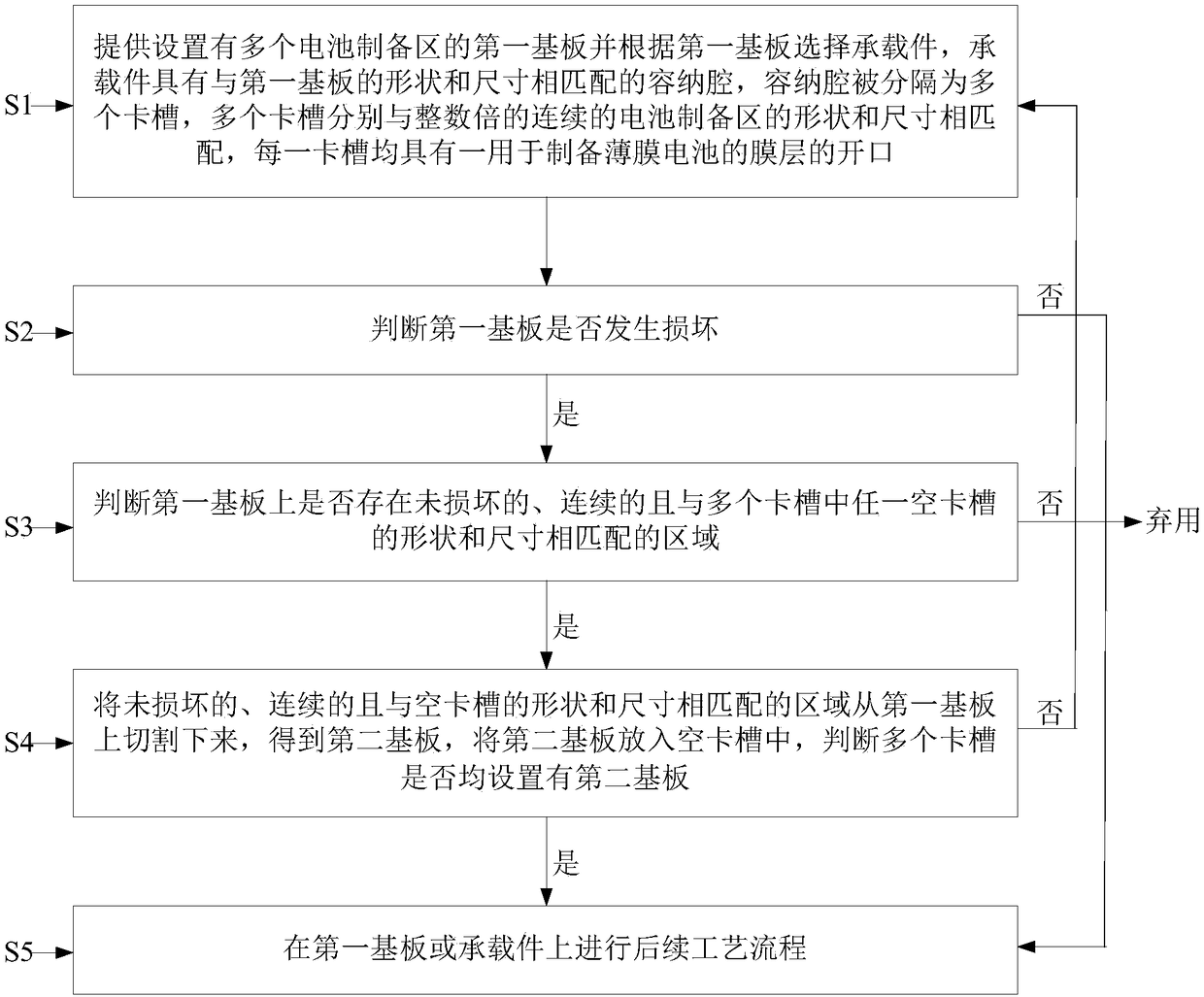

[0033] Please also refer to Figure 1 to Figure 5 , the first embodiment of the present invention provides a method for manufacturing a thin film battery, including:

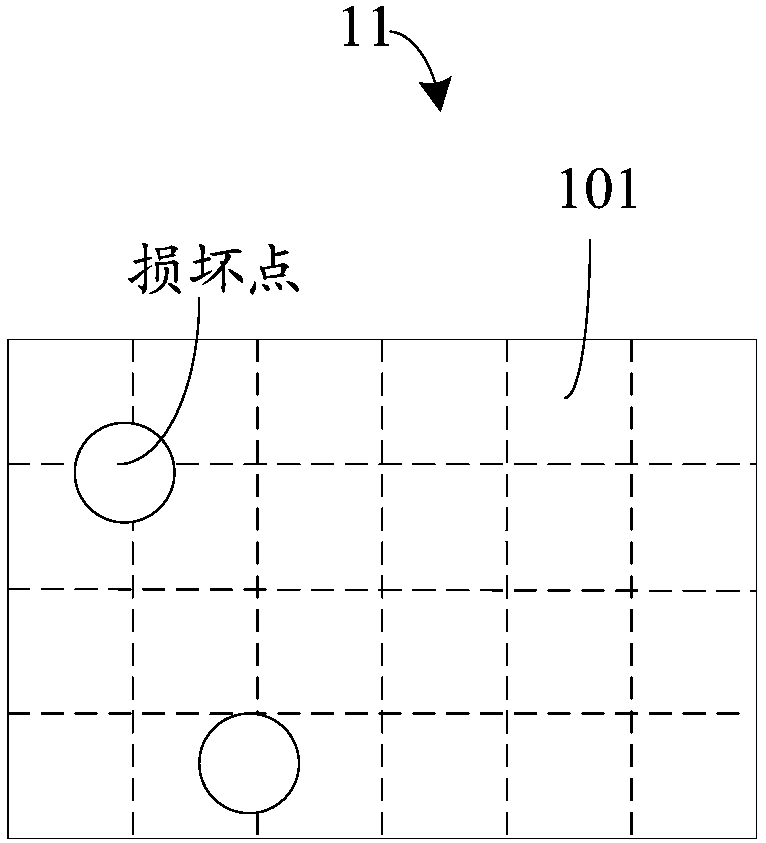

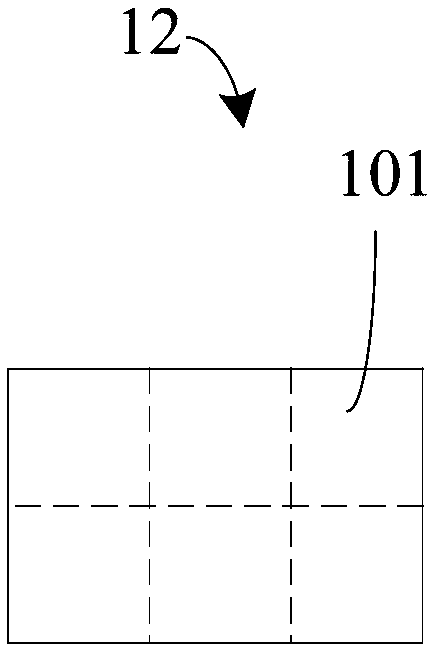

[0034] S1, providing a first substrate 11 provided with a plurality of battery preparation areas 101 and selecting a carrier 20 according to the first substrate 11, the carrier 20 has a housing that matches the shape and size of the first substrate 11 cavity, the accommodating cavity is divided into a plurality of slots 201, the plurality of slots 201 respectively match the shape and size of the continuous battery pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com