Inductance transformer and fabrication method thereof

A transformer and transformer protection technology, applied in the field of transformers, can solve the problems of the transformer air gap becoming larger, the electrical parameters are unstable, and other circuit interference, etc., to achieve the effect of ensuring stability, avoiding interference, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

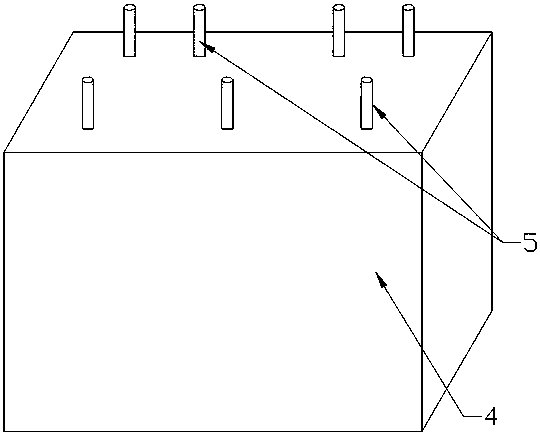

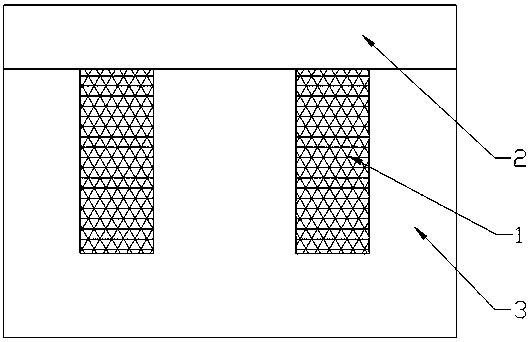

[0017] like figure 1 and figure 2 As shown, the inductance transformer of the present invention includes a winding 1 and a skeleton, and it also includes a strip-shaped silicon steel sheet group 2 and a mountain-shaped silicon steel sheet group 3, and the winding 1 is set in the middle of the mountain-shaped silicon steel sheet group 3 On the strip group, the strip-shaped silicon steel sheet group 2 is located on the side of the mountain-shaped silicon steel sheet group 3 with openings, and the skeleton surrounds the winding 1, the strip-shaped silicon steel sheet group 2 and the The periphery of the mountain-shaped silicon steel sheet group 3 forms the main body of the transformer, and a transformer protection box 4 is also arranged on the periphery of the skeleton. The main body of the transformer is located in the transformer protection box 4 and other gaps in the transformer protection box 4 Filled with epoxy resin. The frame is provided with several pins 5 exposed from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com