Manufacturing method of oriented film and display panel

A manufacturing method and technology for display panels, which are applied in optics, instruments, nonlinear optics, etc., can solve the problem that it is difficult to meet the narrow frame of TFT-LCD panels, and achieve the effect of good film thickness uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

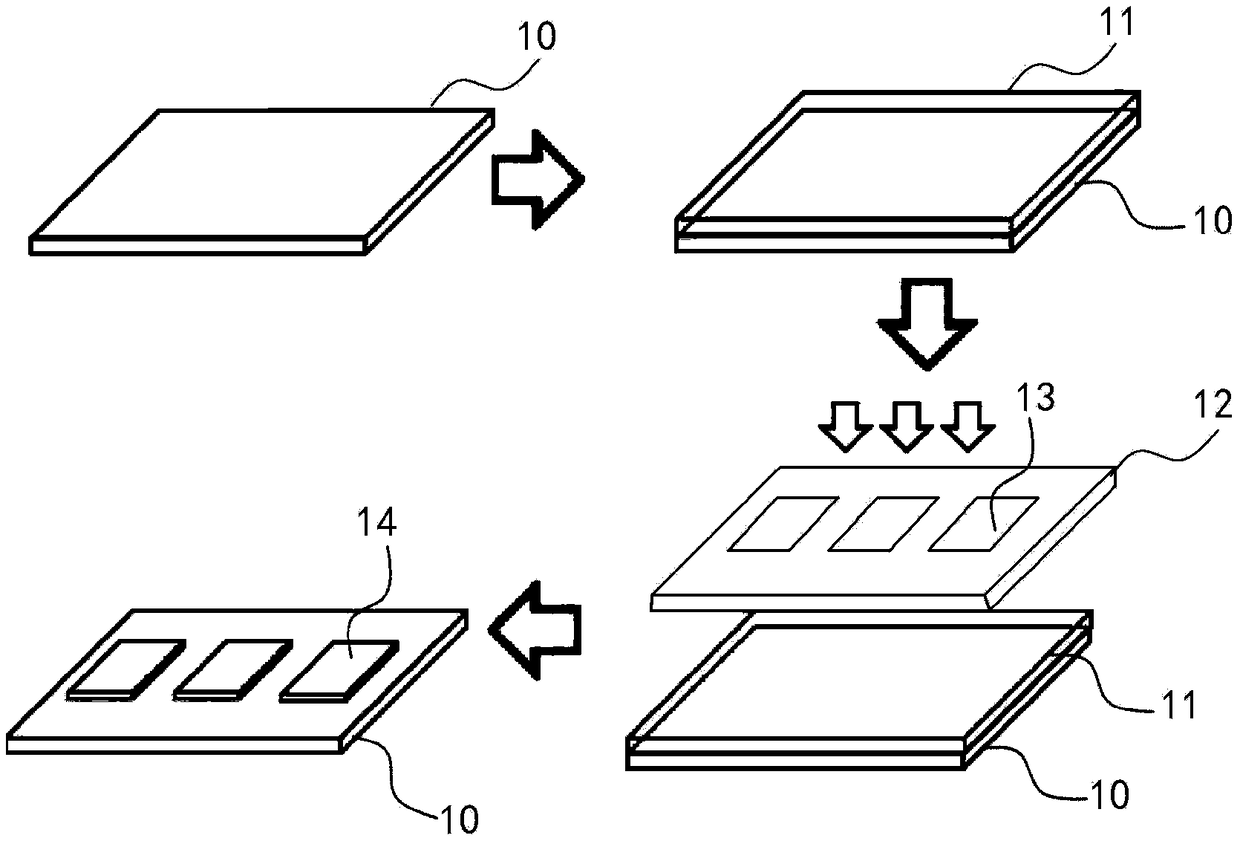

[0032] The technical solutions of the present invention will be further described below according to specific embodiments. The protection scope of the present invention is not limited to the following examples, which are listed for illustrative purposes only and do not limit the present invention in any way.

[0033] It should be understood that the drawings disclosed herein are not necessarily drawn according to the scale of actual devices and components. The shapes and thicknesses of the embodiments may be exaggerated in the drawings in order to clearly show the features of the embodiments of the present invention. In addition, the structures and devices in the drawings are shown schematically in order to clearly show the features of the embodiments of the present invention.

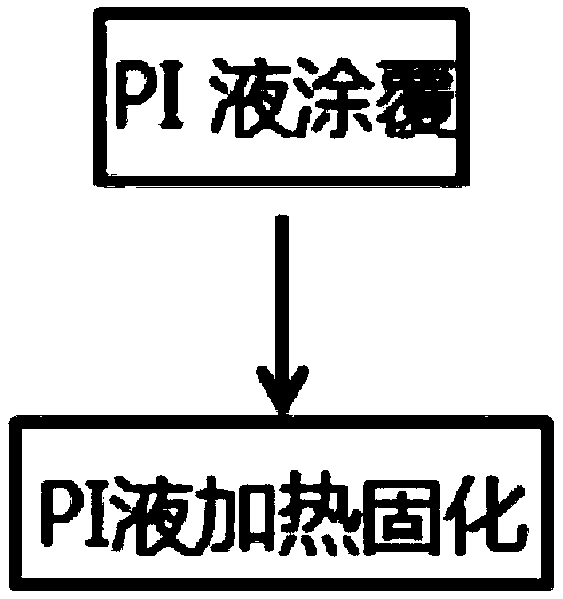

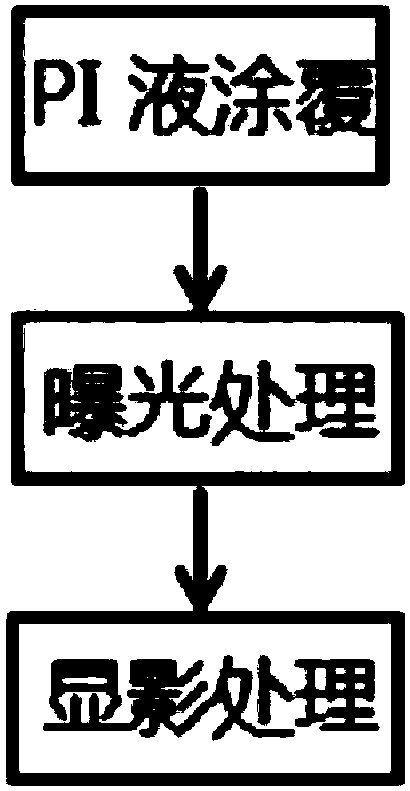

[0034] figure 2 It is a flowchart of a method for manufacturing an alignment film according to an embodiment of the present invention, such as figure 2 As shown, the manufacturing method of the al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com