Impact vibration test device of top coal gangue and application of test device

A test device, impact vibration technology, applied in the direction of vibration test, impact test, measuring device, etc., can solve the problems of restricting the practical application of coal gangue identification technology, imperfect identification methods, lack of experimental equipment, etc., to achieve the diversification of the experimental process, The effect of ingenious structural design and precise test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

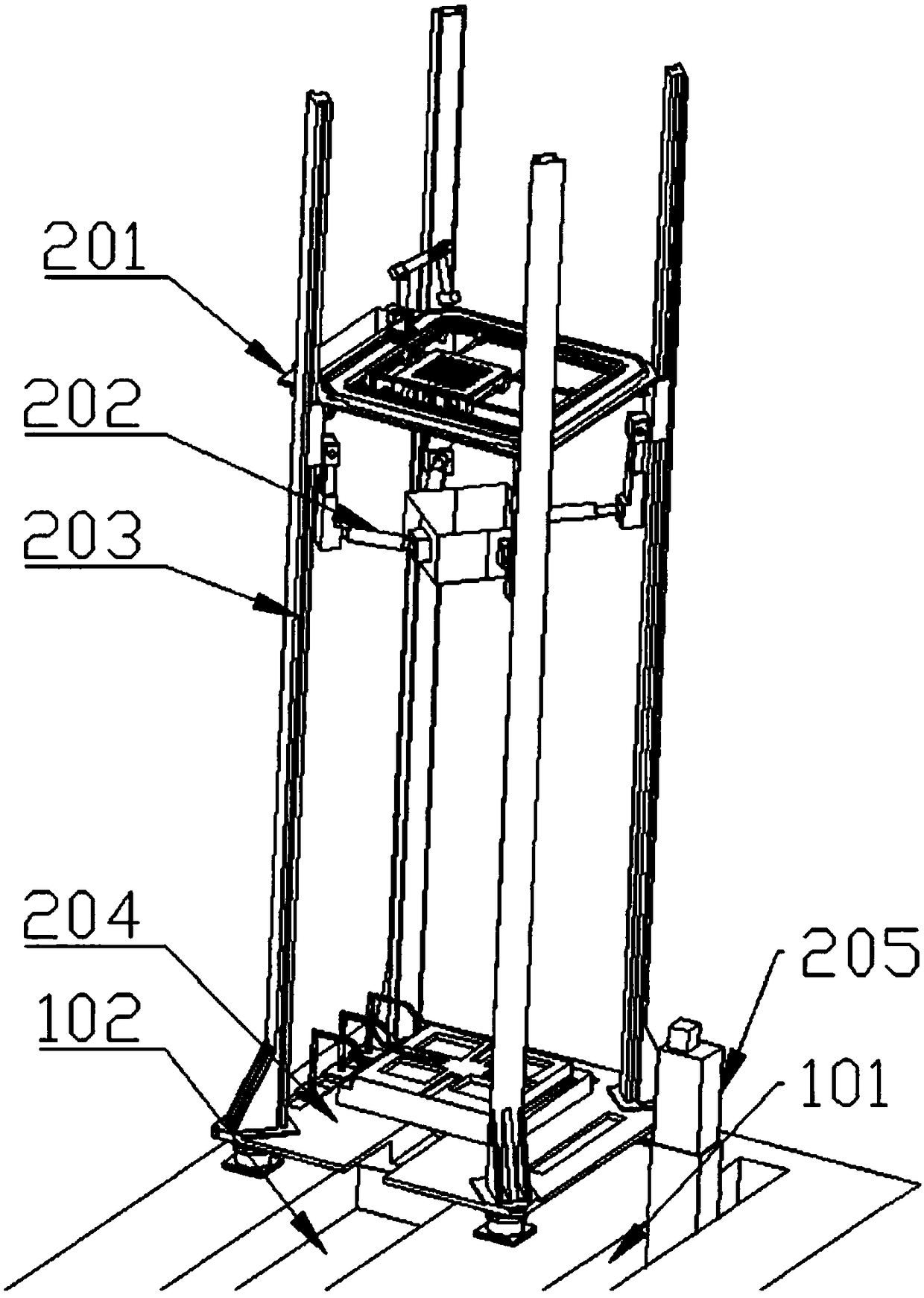

[0058] Such as Figure 1 to Figure 13 As shown, the present embodiment provides a caving coal gangue impact vibration test device, including a base 1 and a vibrating table device 3, a bracket assembly, a coal caving device 2 and a high-speed camera assembly 205 arranged on the base, wherein the vibration The table device 3 is arranged at the bottom of the support assembly, the coal discharge device 2 is arranged on the support assembly and above the vibrating table device 3 , and the high-speed camera assembly 205 is located on one side of the support assembly and arranged side by side with the vibrating table device 3 .

[0059] Specifically, the base 1 is a flat steel plate with a plurality of chutes on it, the vibrating table device 3 and the high-speed camera assembly 205 are placed in the chute, and the vibrating table device 3 can be shifted to adjust its position in the chute , so that the vibrating table device 3 is placed under the entire coal discharge device 2, the ...

Embodiment 2

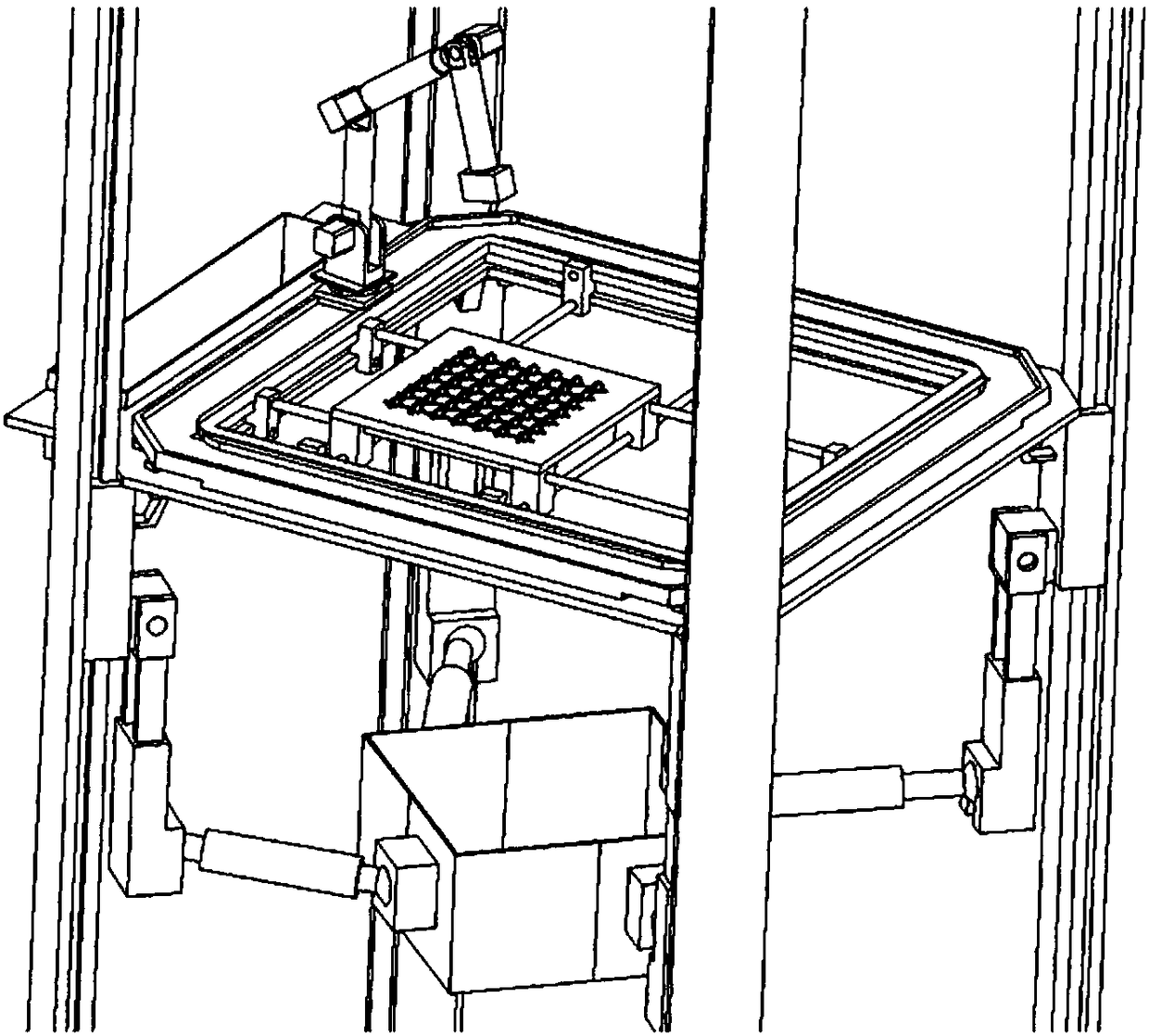

[0068] A caving coal gangue impact vibration test device, the structure is as described in Example 1, the difference is that a coal gangue particle storage box 14 is installed on one side of the first lifting plate 11, and A four-degree-of-freedom manipulator 16 is arranged on one side of the multi-particle coal discharge workbench 13, and the four-degree-of-freedom manipulator 16 is installed in the chute on the upper surface of the multi-particle coal discharge workbench 13 through the manipulator sliding seat 15, which can realize the four-degree-of-freedom manipulator. The space of 16 rotates 360 degrees, and the four-degree-of-freedom manipulator 16 is adjacent to the coal gangue particle storage box 14. Subsequently, the four-degree-of-freedom manipulator 16 grabs the gangue particles stored in the gangue particle storage box 14 and places them in the corresponding coal gangue particle discharge port.

Embodiment 3

[0070] A caving coal gangue impact vibration test device, the structure of which is as described in Embodiment 1, the difference is that: the vibration table device also includes a box-shaped plate fixed and constrained vibration table assembly 302, a box-shaped plate fixed and constrained vibration table assembly 302 Including the vibrating table mobile base 39, the vibrating table secondary mobile seat 40, the vibrating table support sliding groove 41, the vibrating table first lifting support 42, the vibrating table second lifting support 43, the vibrating table third lifting support 44 , Box-shaped vibrating plate fixing rod 48, box-shaped vibrating plate 49, vibrating table material recovery device. Among them, the vibrating table material recovery device also includes the aggregate main body box 50, the aggregate lateral first baffle 51, the aggregate lateral second baffle 52, the aggregate lateral third baffle 53, the aggregate mountain plate The first telescopic rod 54...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com