Integrated flower pool type ecological soil blocking building block and assembly type soil blocking wall

A one-piece, retaining wall technology, applied in the field of building materials, can solve problems such as poor durability and weak overall stability, achieve good overall stability, improve construction speed and quality, and meet economic and structural safety requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

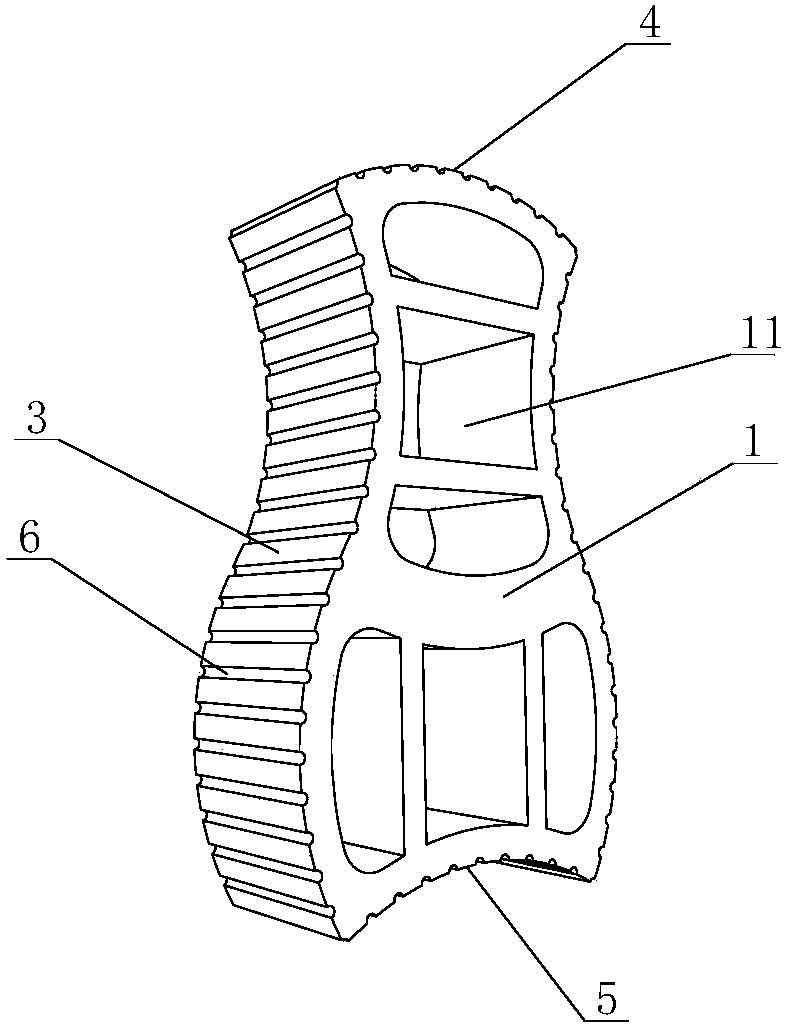

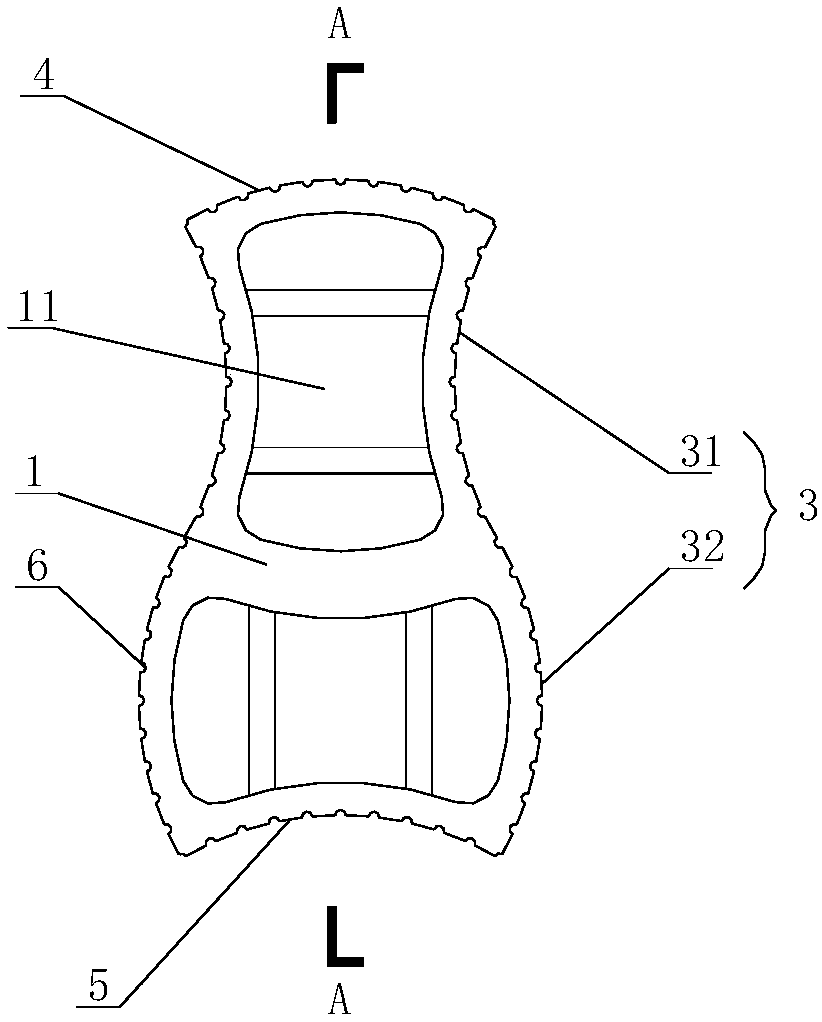

Embodiment 1

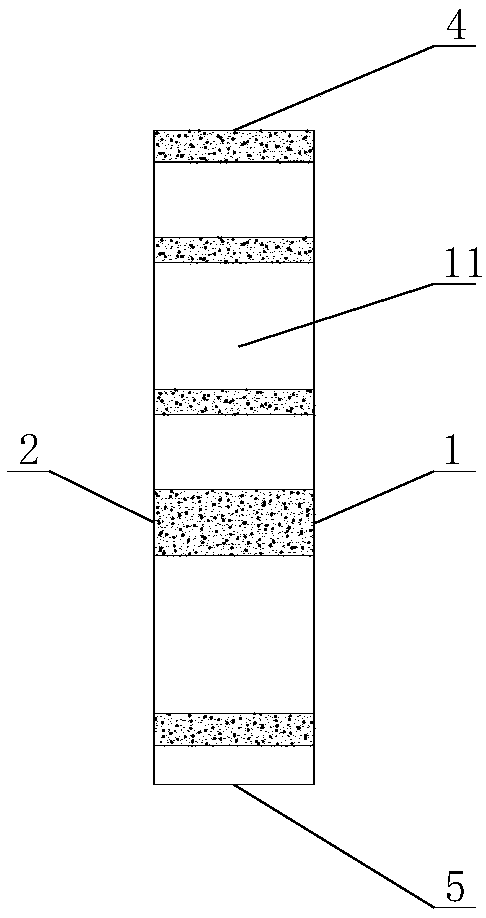

[0087] Single-row setbacks are built with joints. see Figure 8 and Figure 9 As shown, the prefabricated retaining wall provided by the embodiment of the present invention is formed by stacking several f-layer block layers from bottom to top, and each layer f-layer block layer includes several connected block segments, and each block block The segment is formed by sequentially connecting a number of blocks with a-shaped structure end to end, and a block with b-shaped structure or a block with c-shaped structure is connected between each adjacent two block segments.

[0088] see Figure 10 As shown, in every two adjacent block layers, the one-piece block on the upper layer and the corresponding one-piece block on the lower layer are staggered inwards (that is, toward the bank slope) in the vertical direction, forming a setback structure. Specifically, in every two adjacent block layers, at least one first through hole 11 of the conjoined block in the lower layer is not blo...

Embodiment 2

[0090] Single-row setbacks are built with staggered joints. see Figure 11 As shown, the prefabricated retaining wall provided by the embodiment of the present invention is composed of several f-layer block layers and g-layer block layers alternately stacked from bottom to top, and each adjacent two block layers are located on the upper layer The conjoined blocks of the first floor and the corresponding conjoined blocks located on the lower floor are staggered vertically inwards (that is, toward the bank slope) to form a setback structure. Specifically, in every two adjacent block layers, at least one first through hole 11 of the conjoined block in the lower layer is not blocked by the corresponding conjoined block in the upper layer. The unobstructed space can be used as a planting hole, and combined with the design of the setback structure for planting plants, it improves the aesthetics of the prefabricated retaining wall.

[0091] see Figure 12 As shown, the f-layer blo...

Embodiment 3

[0094] Double-row setbacks are built with staggered joints. see Figure 16 As shown, the prefabricated retaining wall provided by the embodiment of the present invention is composed of several h-layer block layers and i-layer block layers alternately piled up from bottom to top, and every two adjacent block layers are located on the upper layer The conjoined blocks of the first floor and the corresponding conjoined blocks located on the lower floor are staggered vertically inwards (that is, toward the bank slope) to form a setback structure. Specifically, in every two adjacent block layers, at least one first through hole 11 of the conjoined block in the lower layer is not blocked by the corresponding conjoined block in the upper layer. The unobstructed space can be used as a planting hole, and combined with the design of the setback structure for planting plants, it improves the aesthetics of the prefabricated retaining wall.

[0095] see Figure 17 As shown, the h-layer b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com