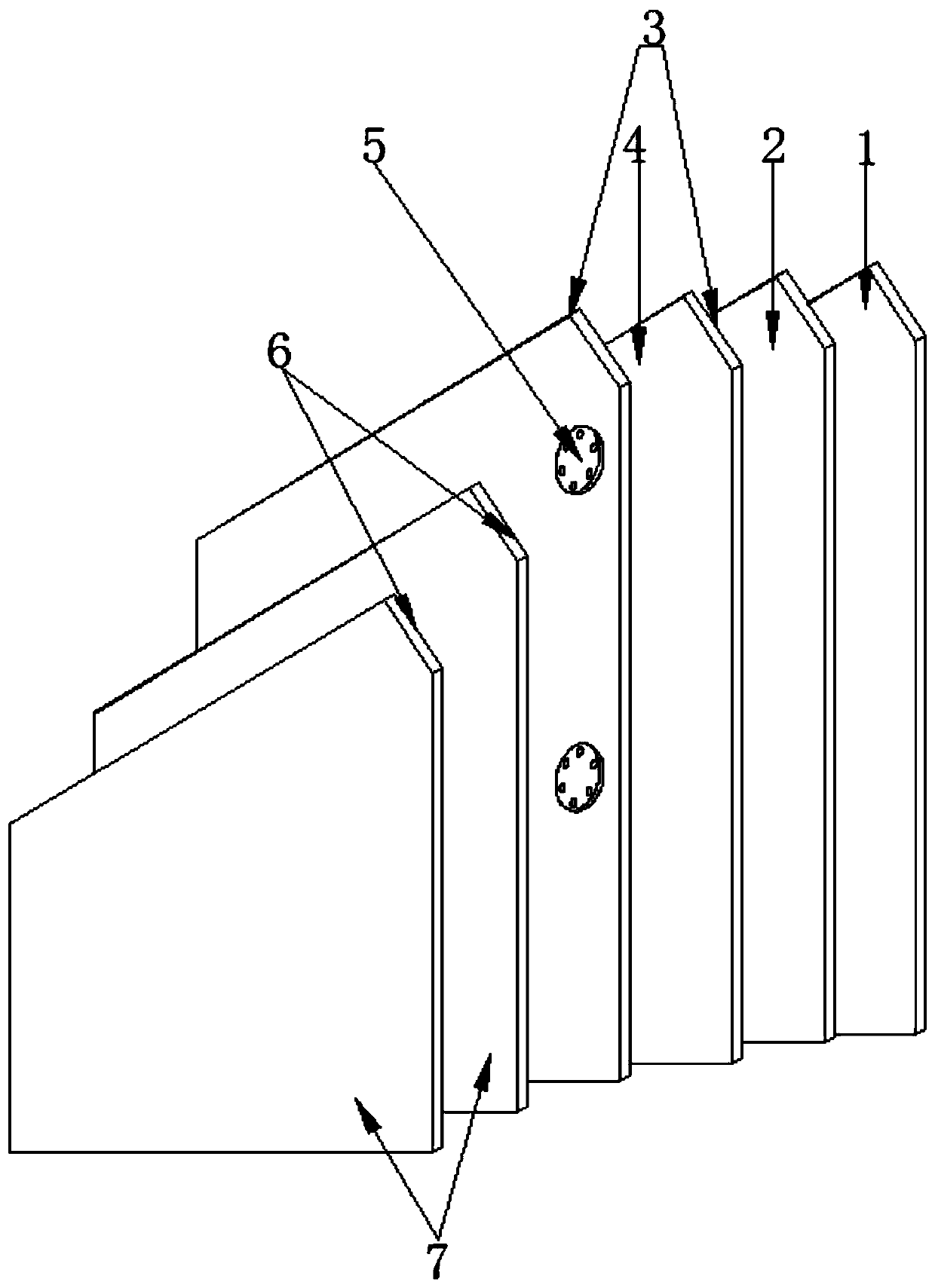

Preparation method of rock wool board heat-insulation system for curtain wall

A technology of thermal insulation system and rock wool board is applied in the field of preparation of rock wool board thermal insulation system for curtain wall, which can solve the problems of high cost and poor thermal insulation effect, and achieve the effects of low cost, good overall stability and improved quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

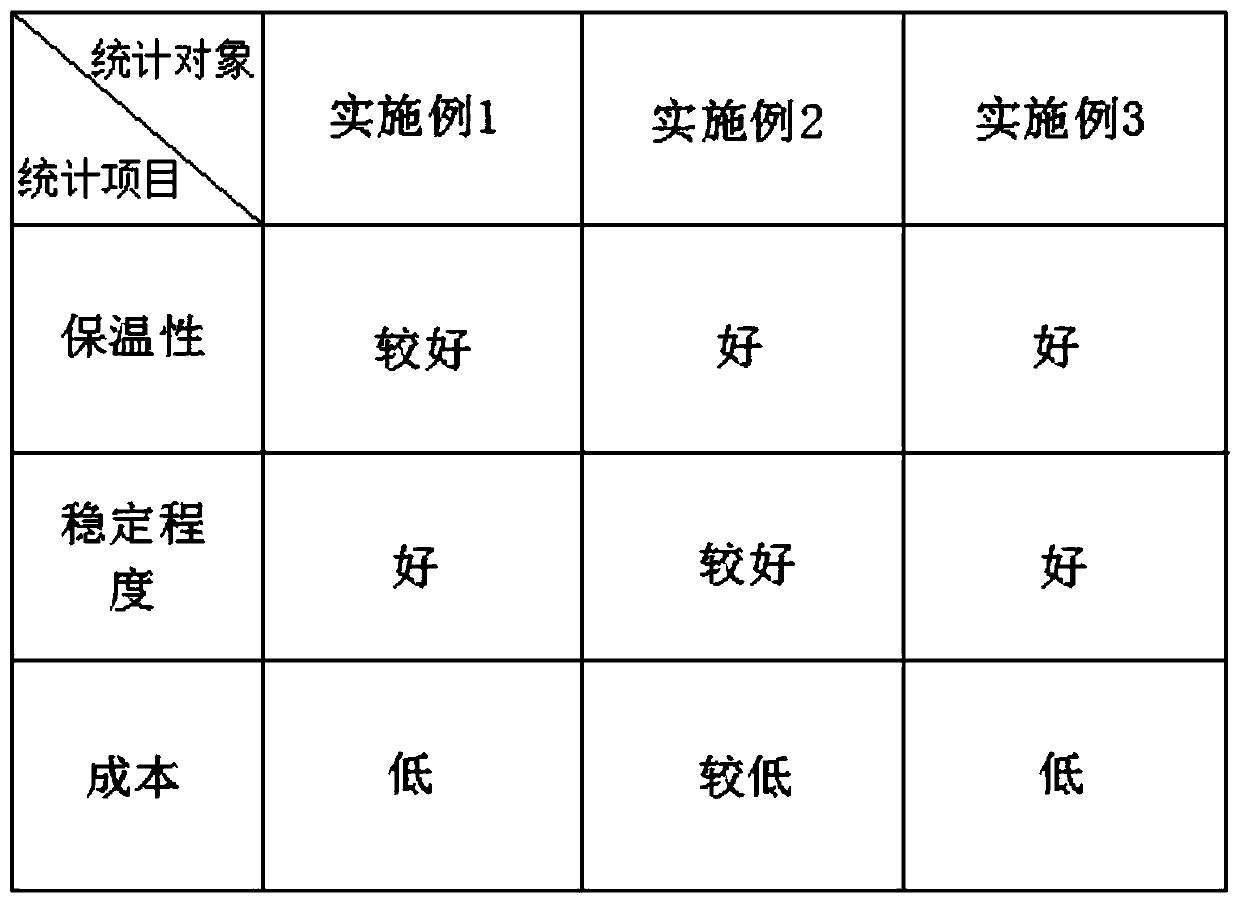

Embodiment 1

[0027] S1. First, clean the wall surface, clean the oil stains and floating ash on the wall surface, remove the loose and windy parts on the wall surface, and then check whether the leveling layer meets the requirements. Horizontal and vertical control lines, expansion joints and decorative sutures of external doors and windows popped up on the surface;

[0028] S2. Pour a certain amount of clean water into a clean material bucket, add the adhesive while stirring with an electric mixer, and stir for 5 minutes until it is evenly mixed and the consistency is moderate. Put it aside, and then put the surface of the rock wool belt Spread the interface agent evenly on the back and the back, and after the interface agent dries naturally, apply the spare adhesive on the back of the rock wool tape;

[0029] S3. After applying the adhesive in S2, the lower end of the rock wool tape should be pasted on the leveling layer first, and then squeezed evenly from bottom to top and slide in pla...

Embodiment 2

[0034] S1. First, clean the wall surface, clean the oil stains and floating ash on the wall surface, remove the loose and windy parts on the wall surface, and then check whether the leveling layer meets the requirements. Horizontal and vertical control lines, expansion joints and decorative sutures of external doors and windows popped up on the surface;

[0035] S2. Pour a certain amount of clean water into a clean material bucket, add the adhesive while stirring with an electric mixer, and stir for 7 minutes until it is evenly mixed and the consistency is moderate. Put it aside, and then put the surface of the rock wool belt Spread the interface agent evenly on the back and the back, and after the interface agent dries naturally, apply the spare adhesive on the back of the rock wool tape;

[0036] S3. After applying the adhesive in S2, the lower end of the rock wool tape should be pasted on the leveling layer first, and then squeezed evenly from bottom to top and slide in pla...

Embodiment 3

[0041]S1. First, clean the wall surface, clean the oil stains and floating ash on the wall surface, remove the loose and windy parts on the wall surface, and then check whether the leveling layer meets the requirements. Horizontal and vertical control lines, expansion joints and decorative sutures of external doors and windows popped up on the surface;

[0042] S2. Pour a certain amount of clean water into a clean material bucket, add the adhesive while stirring with an electric mixer, and stir for 6 minutes until it is evenly mixed and the consistency is moderate. Put it aside, and then put the surface of the rock wool belt Spread the interface agent evenly on the back and the back, and after the interface agent dries naturally, apply the spare adhesive on the back of the rock wool tape;

[0043] S3. After applying the adhesive in S2, the lower end of the rock wool tape should be pasted on the leveling layer first, and then squeezed evenly from bottom to top and slide in plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com