Cleaning liquor, cleaning equipment and cleaning process for silicon chip

A technology for cleaning silicon wafers and cleaning fluids, applied in detergent compositions, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as unfavorable energy saving and environmental protection, high dirty chip rate, and loss of production enterprises, and achieve improvement Cleaning effect, improve cleaning quality, and save cleaning cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] This example is a cleaning solution for silicon wafers, including potassium hydroxide solution with a concentration of 45% and hydrogen peroxide solution with a concentration of 31%, wherein the volume ratio of the potassium hydroxide solution to the hydrogen peroxide solution is 1:4.75.

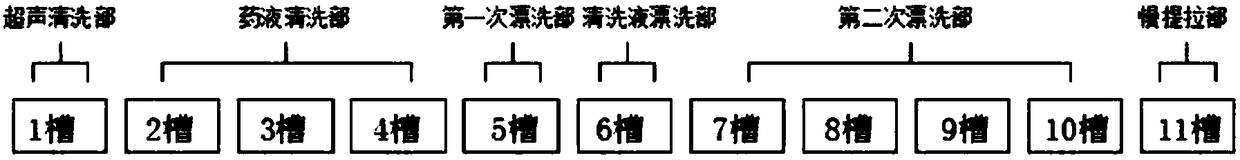

[0034] A silicon wafer cleaning equipment, comprising an ultrasonic cleaning section composed of tanks 1, 2, 3, 4, 5, 6, 7, 8, 9 and 11, and a chemical cleaning section, the first rinsing section, the cleaning liquid cleaning section, the second rinsing section and the slow pulling section, wherein,

[0035] Tank 1 is the ultrasonic cleaning part, which is cleaned by an ultrasonic cleaning tank. The ultrasonic cleaning tank is pure water to pre-clean the silicon wafer. The ultrasonic cleaning tank is an overflow tank. The cleaning time is 160s, and the cleaning temperature is 45 ° C. Silica powder for removing particles;

[0036] The 2-4 tanks form the chemical cleaning part, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com