Method for preparing gear oil

A technology of gear oil and base oil, applied in the field of lubricating oil, can solve the problems of poor oxidation stability of base oil, poor low-temperature fluidity, deterioration of oil quality, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

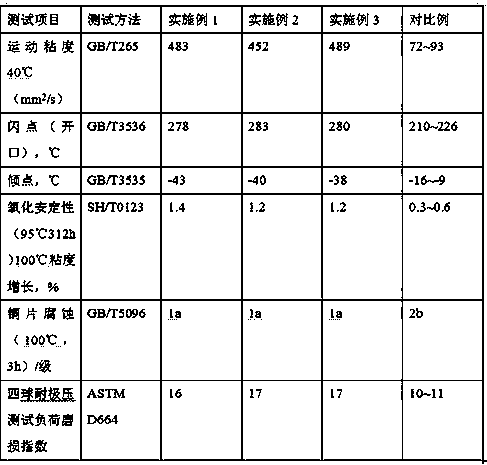

Examples

preparation example Construction

[0017] A preparation method of gear oil, comprising the steps of:

[0018] (1) In terms of parts by mass, take 20~30 parts of rapeseed oil, 50~60 parts of toluene, 10~12 parts of potassium hydroxide, and 20~30 parts of methanol, mix them at 55~60°C for 1~2 hours, Adjust the pH to 7~7.2 to obtain a mixture. In terms of parts by mass, take 20~30 parts of the mixture, 4~6 parts of cation exchange resin, 1~3 parts of acetic acid, and 2~4 parts of hydrogen peroxide. Stir and mix for 6-8 hours, dry with anhydrous sodium sulfate to obtain a dry matrix;

[0019] (2) Take the dry matrix and add cation exchange resin and tert-butanol to mix at a mass ratio of 10:2:50, keep it for 20~30min, then add 20~30% of the dry matrix isopropanol, at 65~70℃ Stir and mix for 7-8 hours, filter, take the filtrate and dry it with anhydrous sodium sulfate, and then vacuum-dry it at 40-45°C to obtain the gear oil base oil for later use;

[0020] (3) According to the number of parts by mass, take 30~40 ...

Embodiment 1

[0024] Cation exchange resin: strongly acidic cation exchange resin CD-450, purchased from Hangzhou Zhengguang Resin Co., Ltd.

[0025] A preparation method of gear oil, comprising the steps of:

[0026] (1) In terms of parts by mass, take 20 parts of rapeseed oil, 50 parts of toluene, 10 parts of potassium hydroxide, and 20 parts of methanol, mix them at 55°C for 1 hour, and adjust the pH to 7 to obtain a mixture. In total, take 20 parts of the mixture, 4 parts of cation exchange resin, 1 part of acetic acid, and 2 parts of hydrogen peroxide, stir and mix at 60°C for 6 hours, and dry with anhydrous sodium sulfate to obtain a dry matrix;

[0027] (2) Take the dry matrix and add cation exchange resin and tert-butanol to mix at a mass ratio of 10:2:50, keep it for 20 minutes, then add isopropanol with 20% of the dry matrix, stir and mix at 65°C for 7 hours, filter, Take the filtrate and dry it with anhydrous sodium sulfate, and then vacuum-dry it at 40°C to obtain the gear oil ...

Embodiment 2

[0032] Cation exchange resin: strongly acidic cation exchange resin CD-450, purchased from Hangzhou Zhengguang Resin Co., Ltd.

[0033] A preparation method of gear oil, comprising the steps of:

[0034] (1) In terms of parts by mass, take 30 parts of rapeseed oil, 60 parts of toluene, 12 parts of potassium hydroxide, and 30 parts of methanol, mix them at 60°C for 2 hours, and adjust the pH to 7.2 to obtain a mixture. In total, take 30 parts of the mixture, 6 parts of cation exchange resin, 3 parts of acetic acid, and 4 parts of hydrogen peroxide, stir and mix at 65°C for 8 hours, and dry with anhydrous sodium sulfate to obtain a dry matrix;

[0035] (2) Take the dry matrix and add cation exchange resin and tert-butanol to mix at a mass ratio of 10:2:50, keep it for 30 minutes, then add 30% isopropanol of the dry matrix, stir and mix at 70°C for 8 hours, filter, Take the filtrate and dry it with anhydrous sodium sulfate, and then vacuum-dry it at 45°C to obtain the gear oil b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com