Reverse-osmosis strong brine treatment device and method for cold rolling wastewater

A treatment method and treatment device technology, which is applied in metallurgical wastewater treatment, water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problem of large impact, high requirements for carbon source dosing control, and difficult to properly handle desorption liquid, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

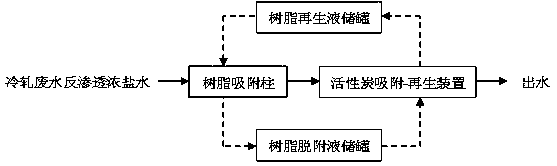

[0037] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0038] The detailed features and advantages of the present invention are described in detail below in the specific embodiments, the content of which is sufficient to enable any person skilled in the art to understand the technical content of the present invention and implement it accordingly, and according to the specification, claims and drawings disclosed in this specification , those skilled in the art can easily understand the related objects and advantages of the present invention.

[0039] figure 1 It shows the treatment process of cold rolling wastewater reverse osmosis concentrated brine according to the present invention. The specific working process and principle are described as follows:

[0040] (1) The reverse osmosis concentrated brine of cold rolling wastewater is first transported into the resin adsorption column, which is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com