A kind of preparation method of carbon nanotube coated silica microsphere composite nanomaterial

A technology of composite nanomaterials and carbon nanotubes, which is applied in the field of metal matrix composite materials preparation, can solve the problems of few researches on carbon nanotubes coated with nanometer microspheres, and achieve the effects of low density, low cost and good elasticity and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

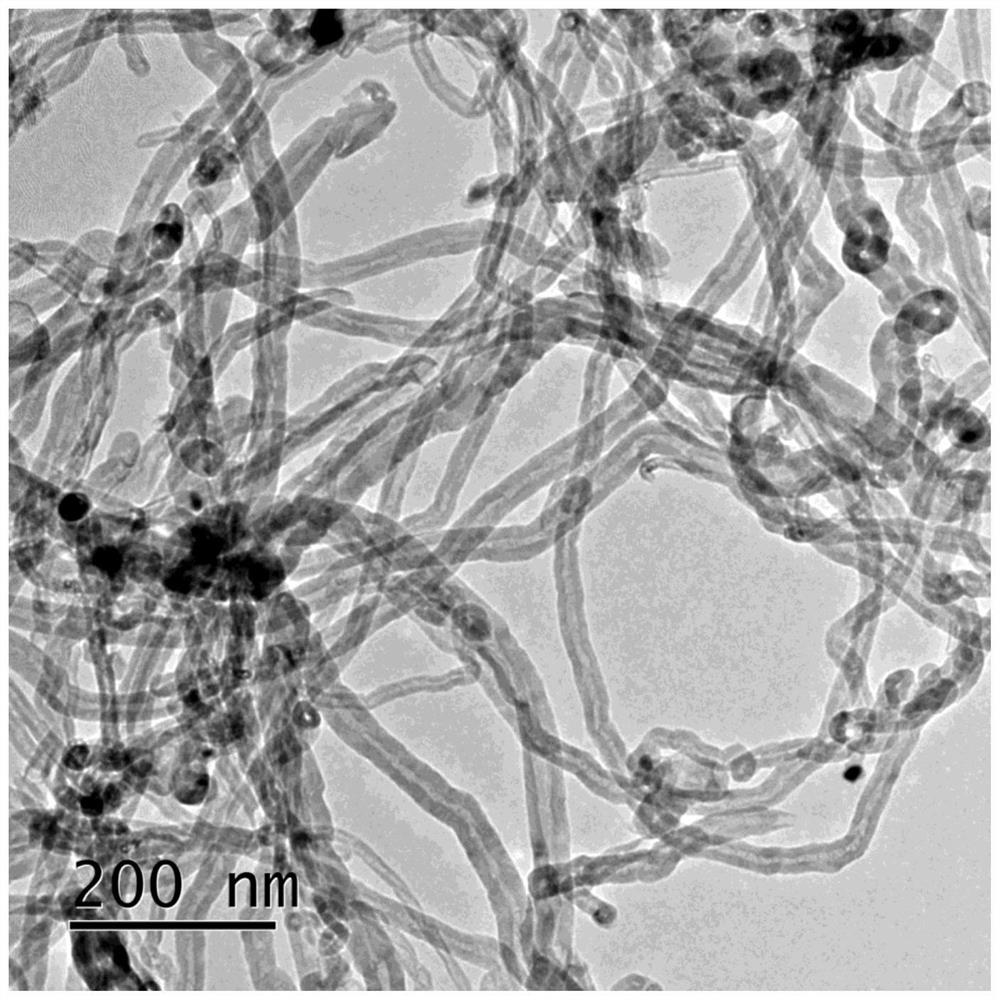

Image

Examples

Embodiment 1

[0047] Step 1, add absolute ethanol, deionized water and ammonia solution with a mass concentration of 25% in a volume ratio of 50:1:3 to a 250ml three-necked bottle, stir in a water bath at 25°C at a speed of 250rpm After the stirring started, add ethyl orthosilicate (the volume ratio of ethyl orthosilicate to absolute ethanol is 3:50) into the three-necked bottle, react for 6 hours, let it stand for 20 minutes, and then centrifuge at 8000rpm for 10 minutes , remove the upper clear night, wash once with ethanol, wash twice with water, and dry at 60°C to obtain SiO 2 nanospheres.

[0048] The SiO obtained in this step 2 SEM micrographs of the microspheres figure 2 Shown, SiO 2 The microspheres are regular spheres with smooth surfaces and uniform sizes, with diameters ranging from 400 to 500 nm.

[0049] Step 2, the nano-SiO 2 The microspheres were added to the CTAB solution with a mass concentration of 2% (nano-SiO 2 The mass volume ratio of the microspheres to the CTAB...

Embodiment 2

[0055] Step 1, add absolute ethanol, deionized water and ammonia solution with a mass concentration of 26% in a volume ratio of 50:10:3 to a 250ml three-neck bottle, stir in a water bath at 26°C at a speed of 255rpm After stirring, add ethyl orthosilicate (the volume ratio of ethyl orthosilicate to absolute ethanol is 3:51) into the three-necked bottle, react for 6.5 hours, let it stand for 22 minutes, and then centrifuge at 8500rpm 10min, remove the upper clear night, wash with ethanol twice, wash with water three times, and dry at 60°C to obtain SiO 2 nanospheres.

[0056] Step 2, the nano-SiO 2 The microspheres were added to the CTAB solution with a mass concentration of 2.2% (nano-SiO 2 The mass volume ratio of the microspheres to the CTAB aqueous solution is 1.1g / 300ml), after stirring with a magnetic stirrer at room temperature for 26min, ultrasonically disperse at 42°C for 1.5h, and after standing for 3.5h, pass N 2Carry out reflux stirring, add MMA monomer and initi...

Embodiment 3

[0061] Step 1, add absolute ethanol, deionized water and ammonia solution with a mass concentration of 27% in a volume ratio of 60:1:3 to a 250ml three-necked bottle, stir in a water bath at 27°C at a speed of 270rpm After the stirring started, add tetraethyl orthosilicate (the volume ratio of tetraethyl orthosilicate to absolute ethanol is 3:52) into the three-necked flask, react for 7 hours, let it stand for 25 minutes, and then centrifuge at 9000rpm for 8 minutes , remove the upper clear night, wash once with ethanol, wash three times with water, and dry at 65°C to obtain SiO 2 nanospheres.

[0062] Step 2, the nano-SiO 2 The microspheres were added to the CTAB solution with a mass concentration of 2.5% (nano-SiO 2 The mass volume ratio of the microspheres to the CTAB aqueous solution is 1.2g / 300ml), after stirring with a magnetic stirrer at room temperature for 27min, ultrasonically disperse at 45°C for 1h, let it stand for 4h, and then inject N 2 Carry out reflux stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com