Motor copper rotor die casting device and die casting method

A copper rotor and rotor technology, applied in the field of motor copper rotor die-casting devices, can solve the problems of motor noise, large mold damage, low copper rotor filling rate, etc., and achieve the effects of improving work efficiency, reducing mold heat dissipation, and excellent filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

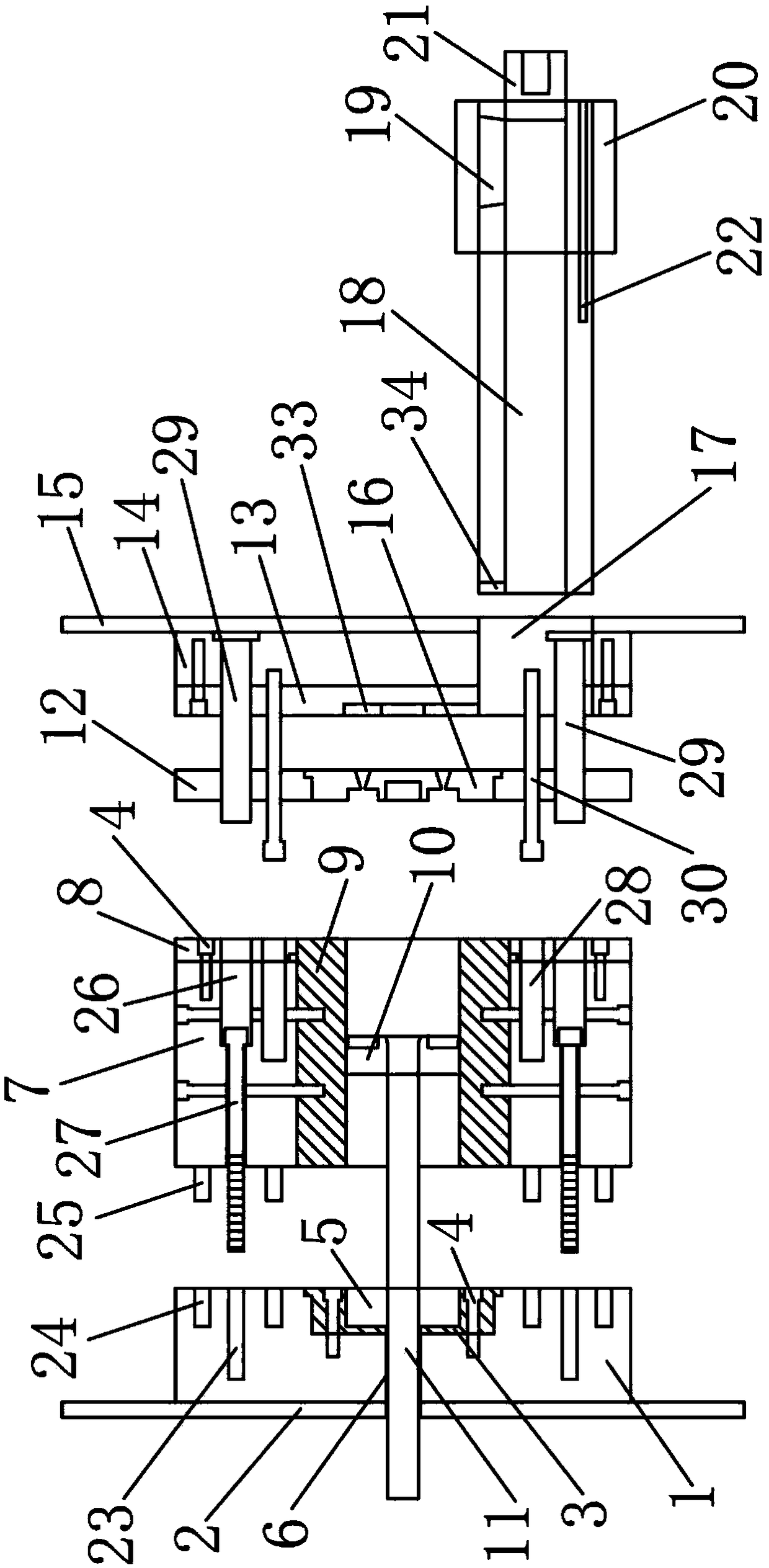

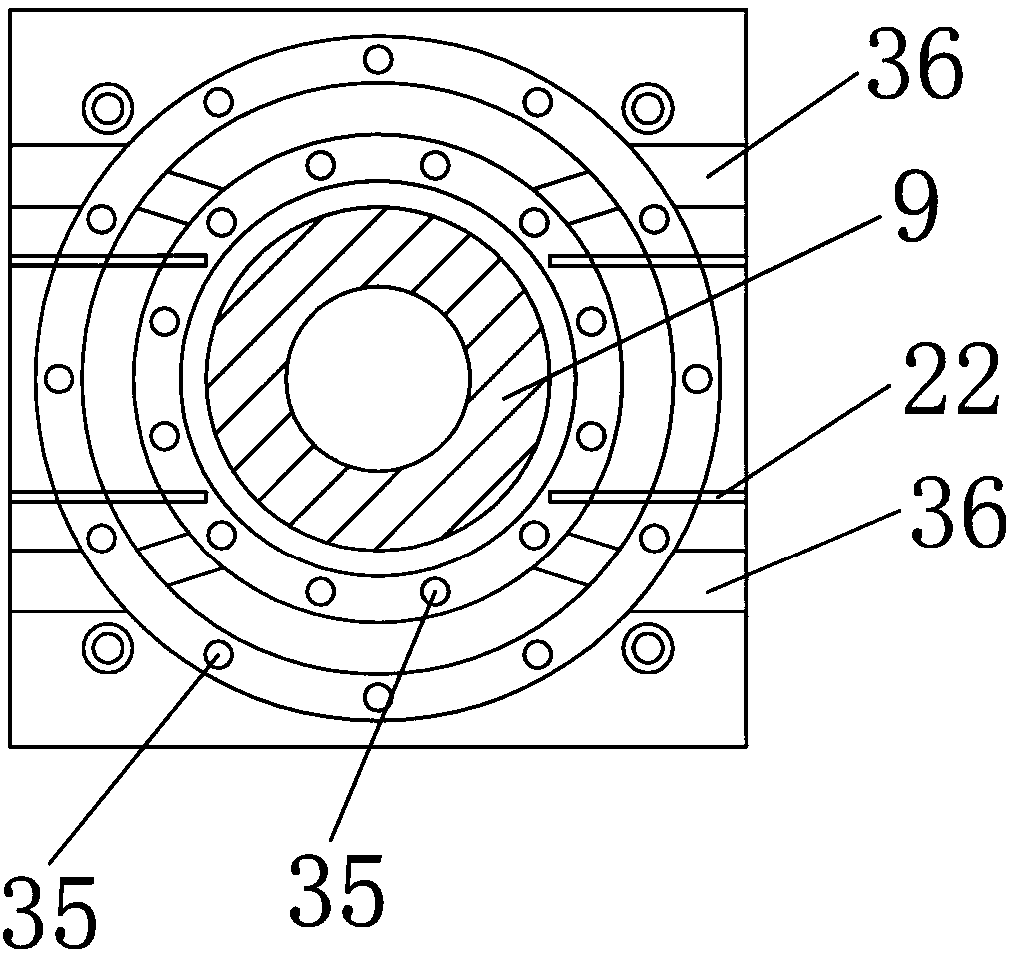

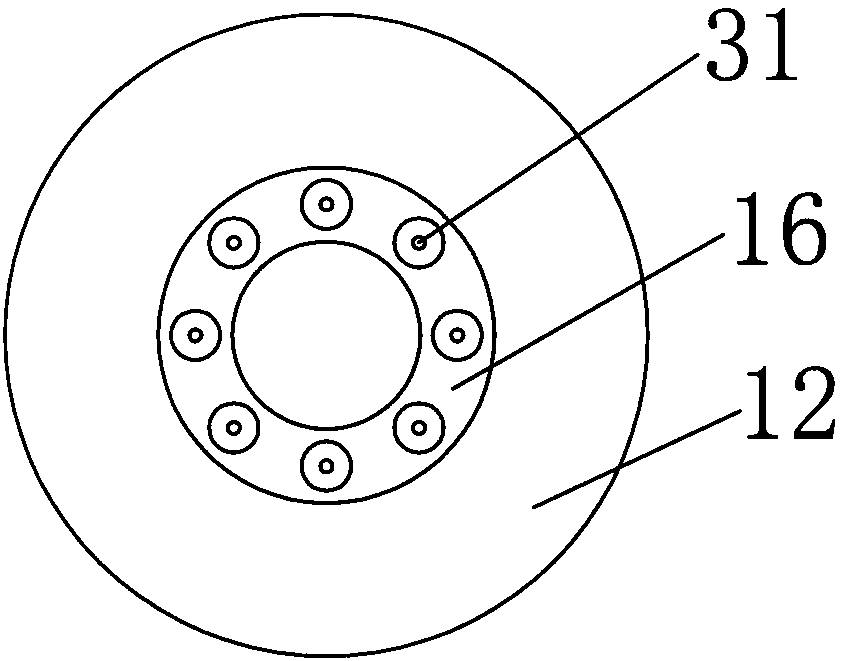

[0022] Embodiment: a kind of motor copper rotor die-casting device, such as Figure 1-Figure 4As shown, it includes a low-frequency induction furnace and a die-casting machine. The heating power of the low-frequency induction furnace is 0-50KW. The die-casting machine includes a front mold assembly, a middle mold assembly, a rear mold assembly and an injection mold assembly. The rear mold Components, middle mold components, front mold components, and injection mold components are arranged in sequence and assembled together; the rear mold component includes a rear mold frame and a rear mold heat shield, and the rear mold heat shield is fixedly arranged on the left side of the rear mold frame. side, the right side of the rear mold base is provided with a mold base, the mold base is coaxial with the rear mold base, and the mold base is fixedly connected with the rear mold base through a screw, and a groove is arranged in the mold base, and the The bottom of the groove is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com