Method for forecasting continuous casting crystallizer steel leakage by adopting spatial density-based clustering DBSCAN

A continuous casting mold and space density technology, which is applied in the field of continuous casting mold breakout prediction using space density clustering DBSCAN, can solve the problems of heavy model maintenance workload, cumbersome setting of time series characteristic values and thresholds, etc. Achieve the effect of avoiding steel breakout accidents and reducing the number of false alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

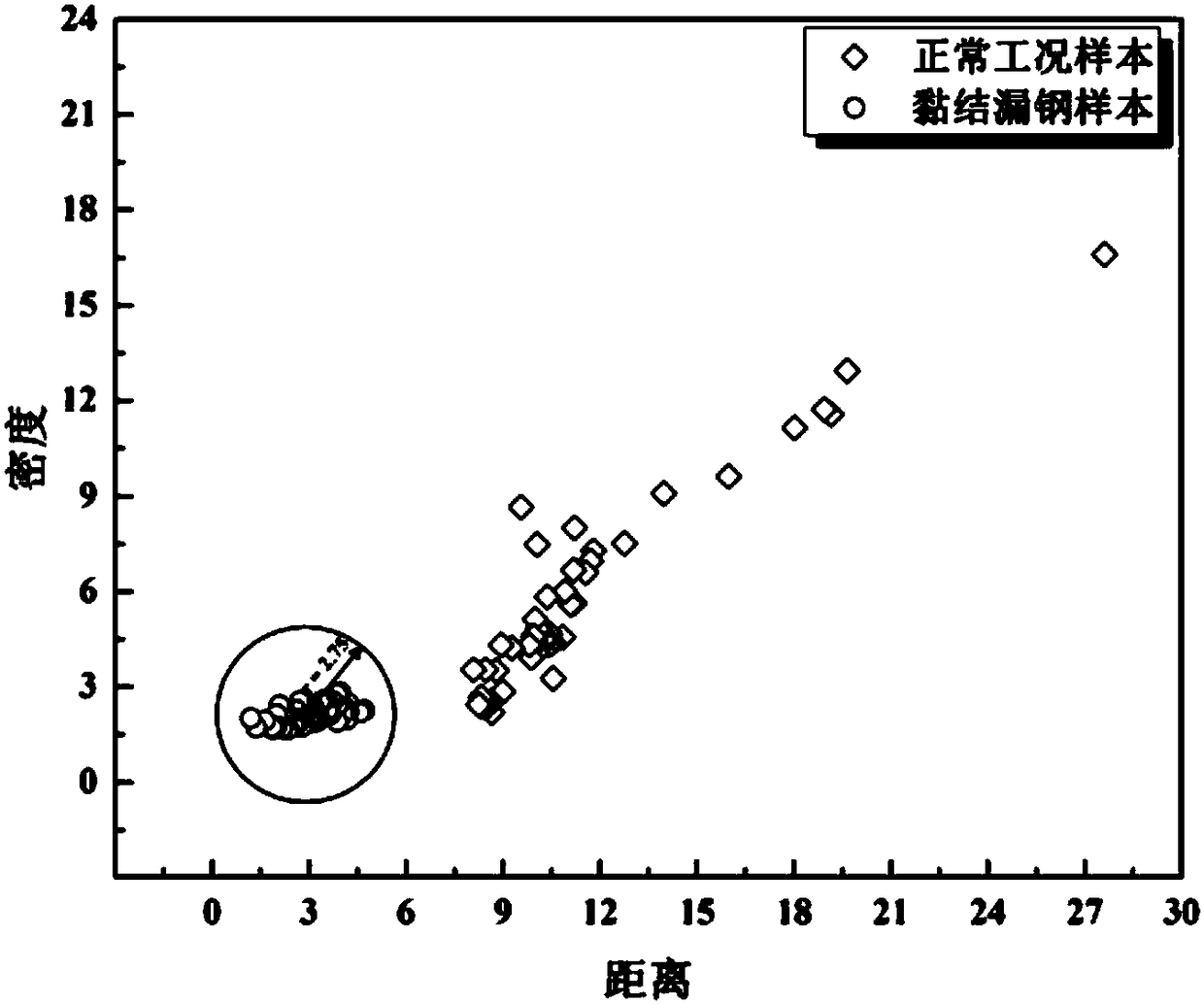

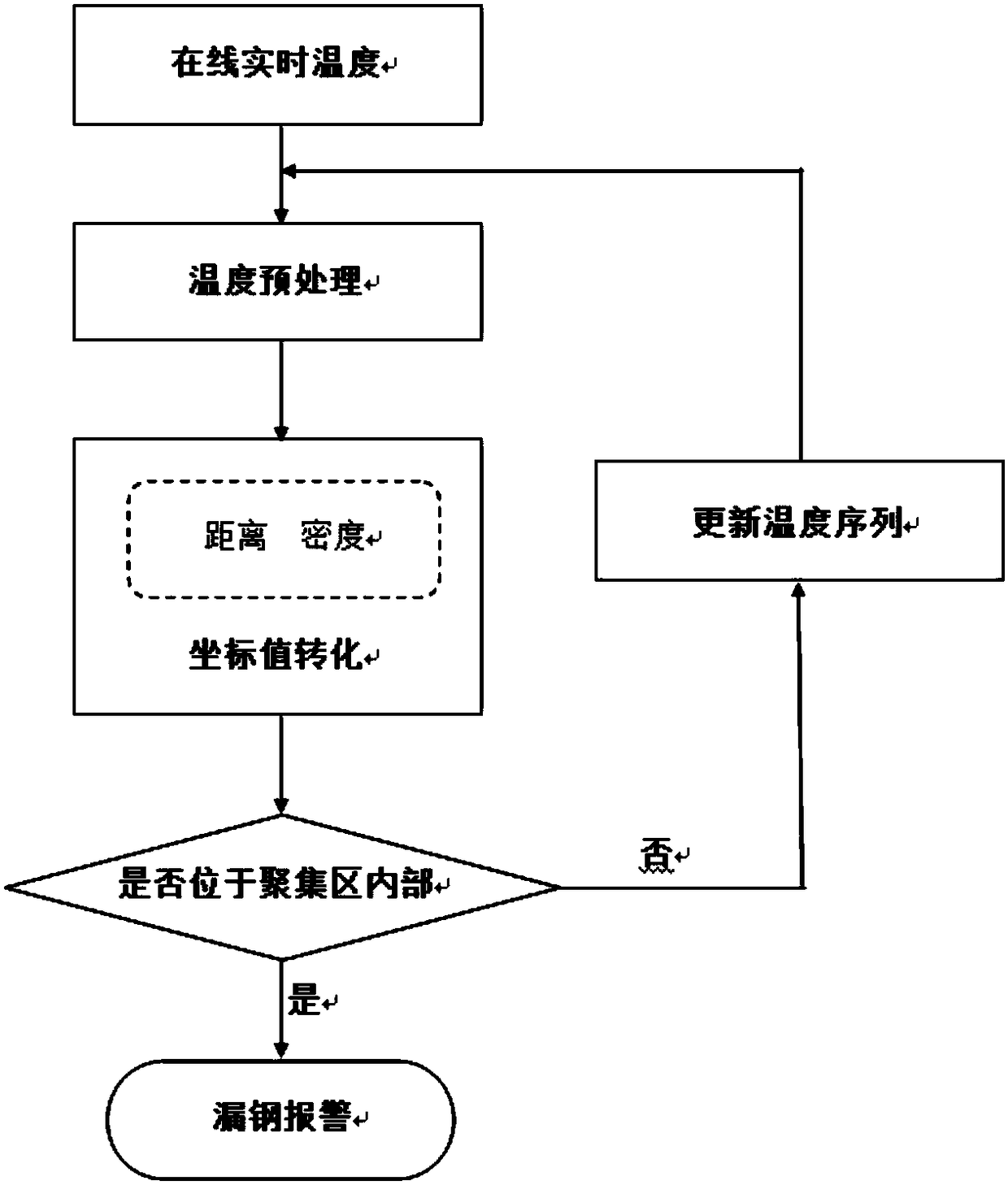

[0073] The invention proposes a method for predicting mold breakout by using density clustering DBSCAN, aiming at solving the technical problem of prediction of bonded breakout in continuous casting production process. The invention organically combines breakout prediction and cluster analysis, based on the single important feature of breakout temperature mode, uses cluster analysis to dig out the similarity between new temperature sequence and known breakout temperature mode, so as to judge breakout, significantly improve The accuracy rate of steel breakout prediction and the advance amount of alarm are improved.

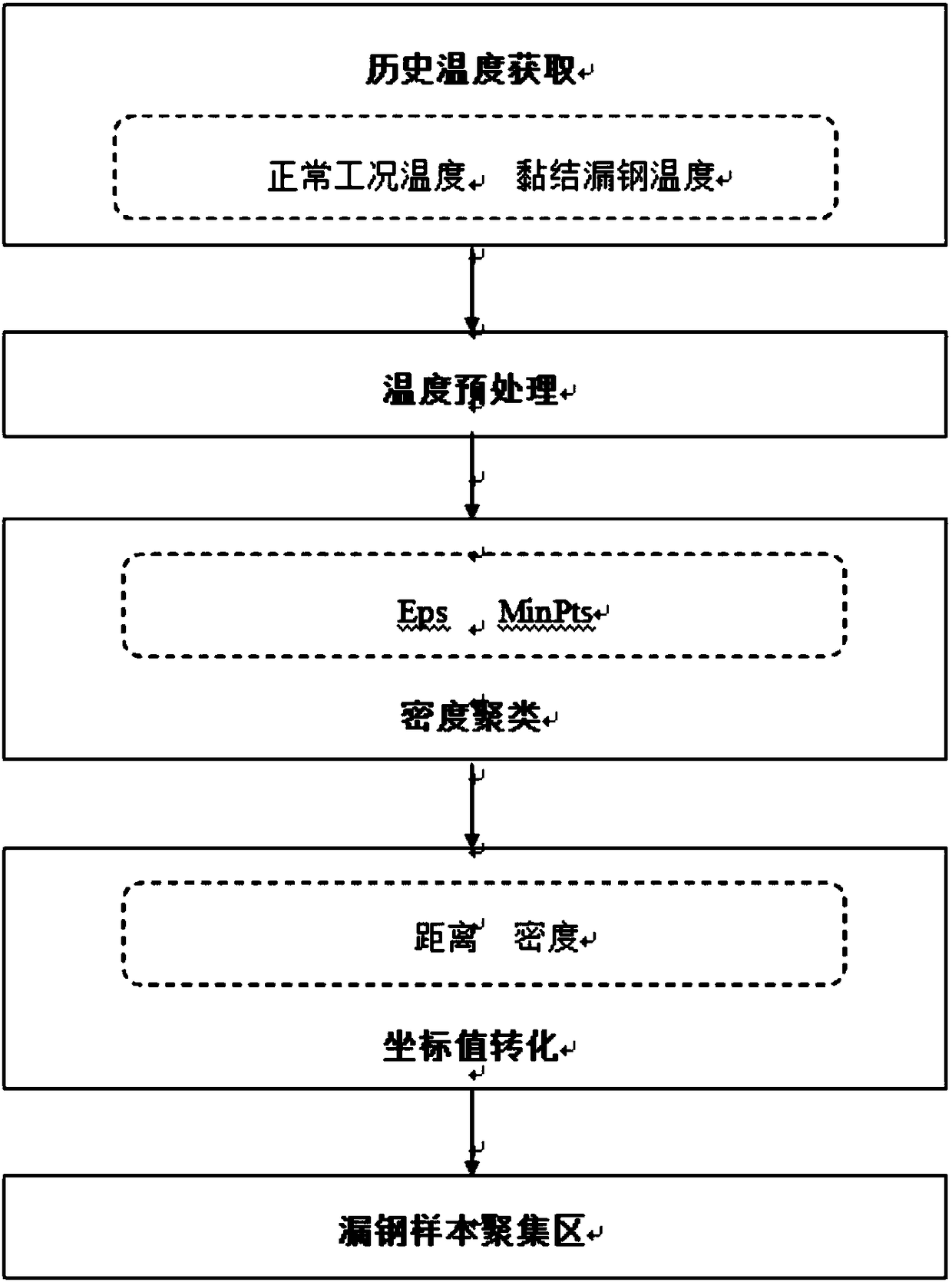

[0074] This method is mainly composed of two parts: the acquisition of the breakout sample gathering area and the identification and judgment of the breakout.

[0075] Step 1. Acquisition of breakout sample gathering area

[0076] figure 1 Shown is the flow chart for the acquisition of the breakout sample gathering area. Depend on figure 1 It can be seen that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com